1. Remove control valve from the backhoe.

2. Thoroughly clean the exterior of the valve before

beginning disassembly procedures.

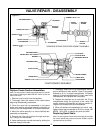

3. At the BACK of the valve remove all bonnet assem-

bly parts which are connected to the spool. Keep

parts in the order of disassembly. See Figure 11 for

the parts involved in the make-up of the bonnet

assembly.

IMPORTANT: DO

NOT remove the spool from the

valve. The seals can be replaced externally. Prevent

spools from turning or moving by inserting a screw dri-

ver through the clevis slot, or by running a rod through

the pin hole and using the rod as a handle. DO NOT

hold the spool with a wrench. This will destroy the fin-

ish.

4. At the BACK of the valve, remove seal retainer,

back-up washer, and spool O-ring seal, or

retaining

sleeve,bonnet O-ring seal and spool U-cup seal.

5. Thoroughly clean counterbores.

6. Install new seals:

A. Spring-Centered Bonnet

Assembly Only:

Lightly oil new O-ring seal. Slide O-ring seal over

valve spool and insert in seal counterbore. Replace

back-up washer and seal retainer.

B. Float Bonnet Assembly Only:

Replace retaining sleeve on valve spool. Lightly oil

new U-cup seal. Slide U-cup seal over valve spool

being careful to orient seal as shown in Figure 11.

Install new O-ring seal in bonnet counterbore.

7. At the BACK of the valve replace bonnet assembly

parts, reversing the order in which they were disas-

sembled in step 3. Use 12 ft. lbs. torque to tighten

assembly screw on spring centered bonnet assembly.

8. At the FRONT of the valve remove all parts con-

nected to the spool (handle, linkage, etc.).

9. At the FRONT of the valve remove seal plate retain-

er, seal retainer, back-up washer and spool O-ring

seal.

10. Thoroughly clean counterbore.

11. Lightly oil new O-ring seal. Slide O-ring seal over

valve spool and insert in seal counterbore. Replace

back-up washer, seal retainer, and seal plate retainer.

12. Reattach all parts connected to the spool (handle,

linkage, etc.).

20

ASSEMBLY

Basic components for all models can be identified in Figure 12. Refer to Page 38 for photographs of units on their shipping pallets.

General:

The backhoe has been partially disassembled and

strapped to a skid for shipping purposes. Initial installa-

tion on the tractor will require a hoist or other device

capable of safely lifting the entire backhoe from the skid.

After the initial installation is complete, the backhoe can

serve as its own erecting hoist, by lowering stabilizers

and bucket to the ground. Additional lifting devices will

not be required for normal removal and reattaching.

Assembly(865H & 965H) - Figure 12

IMPORTANT: Tighten all hardware to torque require-

ments specified in torque chart.

1. Remove the stabilizer assemblies and any miscellaneous

items which have been fastened to the skid and arrange

conveniently. Reposition Stabilizer Cylinders from their ship-

ping configuration, by assembling them into the mainframe,

using the hardware provided. Be sure cylinder ports are

pointed upward and hoses are routed above the cylinder to

mainframe pivot pin connection. Refer to page 38.

Figure 12

CAUTION

DO NOT cut any strapping that

fastens the backhoe mainframe

and swing frame to the skid base

at this time.

CAUTION

Be sure hoist being used is suit-

able, has sufficient capacity and

is in the proper position. Do not

allow anyone under a backhoe

member supported by hoist.

C

B

E

D

A

I

G

H

F

2. Support boom(A) and dipperstick (B) with hoist and

remove boom transport lock pin. Lower boom and

manually extend dipperstick until it rests on ground.

Move control handle to “BOOM DOWN” position as

required to aid movement.