28

370406 F103104A

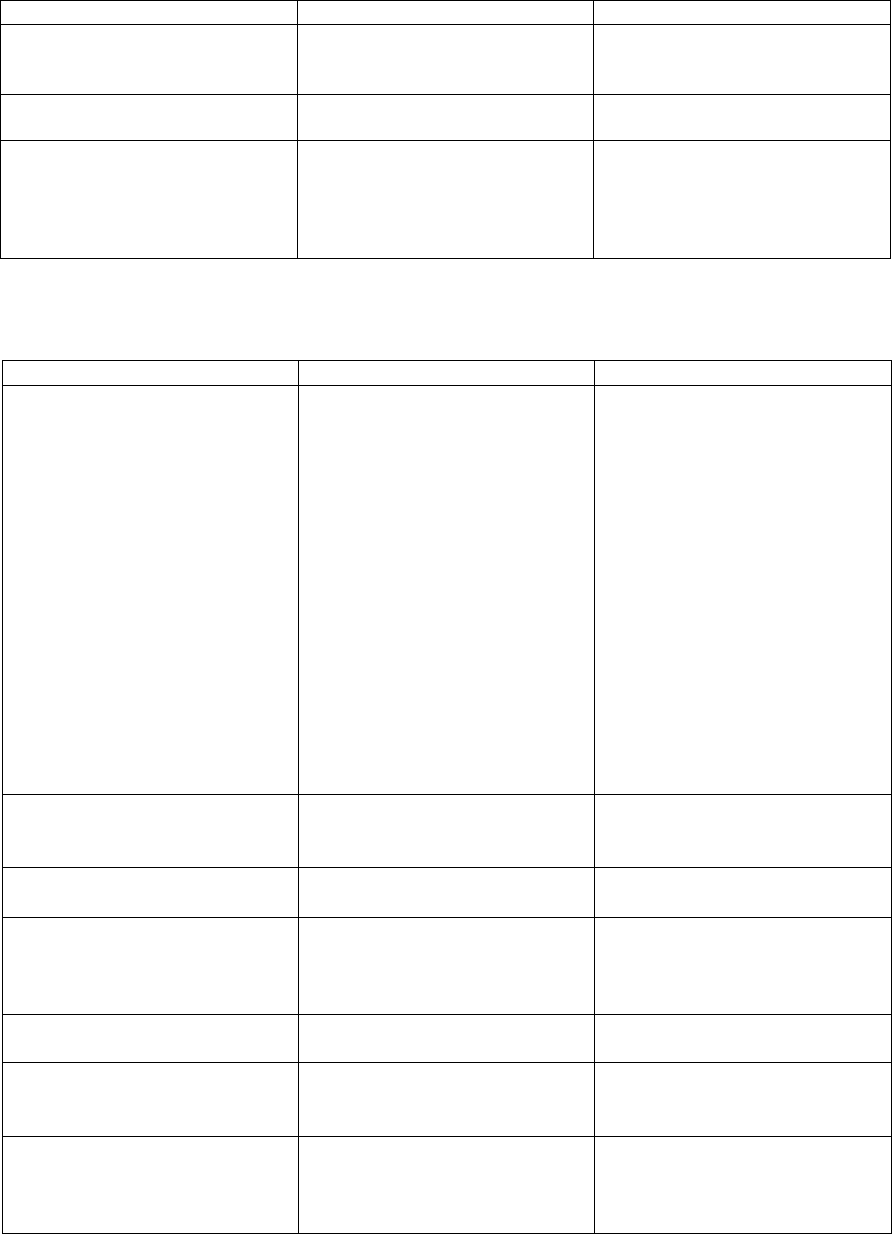

21. TROUBLESHOOTING

The following table illustrates some problems which may arise during operation.

ENGINE

FAULT CAUSE MEASURES TO BE TAKEN

Engine sluggish at switch on 1. accelerator not in start-up

position

2. Choke not closed

3. Petrol does not arrive

4. Air bubbles or water inside

the petrol lines

5. Thick oil prevents rotation

6. Winding or start

mechanism faulty

7. Spark plug in poor

condition

1. move the accelerator to the

intermediate position

2. Close the choke when cold.

3. Check the fuel tank and

remove any water or

sediment.. Make sure that

the feed cock is open.

4. Check the lines and bands.

Repair or replace if

damaged

5. Use oil with a viscosity

suited to the temperature

6. Replace winding or start

mechanism

7. Clean or replace spark

plug. Adjust the distance

between the electrodes.

Poor power 1. No fuel

2. Air filter blocked

3. Elastic bands worn

1. refill tank with petrol

2. clean air filter

3. replace elastic bands

Engine stalls 1. no fuel

2. feed cock shut off

1.

refill tank with petrol

2.

open feed cock

Exhaust fumes dark 1. low grade fuel

2. too much engine oil

1. replace with high grade

fuel

2. restore engine oil to correct

level

Engine emits black smoke and

power is poor

1. air filter blocked

2. choke not fully opened

1. clean air filter

2. open the choke completely

Exhaust fumes bluish 1. too much engine oil

2. elastic bands worn

1. restore engine oil to correct

level

2. replace elastic bands

Silencer becomes red through

overheating

1.

ir filater blocked

2.

Inside of self-winding

starter blocked with grass

cuttings

1.

clean air filter

2.

clean self-winding starter

housing

For any problems not easily resolved or in case of doubt you are advised to contact

your dealer.

FAULT CAUSE MEASURES TO BE TAKEN

Belt slips 1. Belt tension inadequate

2. Too great a working depth

3. Belt worn

1. Adjust the belt tension

2. Reduce the working depth

3. Replace belt

Machine vibrates excessively 1. Belt damaged

2. Blade bent or broken

1. Replace belt

2. Replace blade

Engine overloads during work

operations

1. Engine speed too low.

2. Blade worn

3. Forward speed too high

4. Too great a working depth

1. Accelerate to maximum

2. Replace blade

3. Decrease the forward

speed

4. Reduce the working depth