20

370406 F103104A

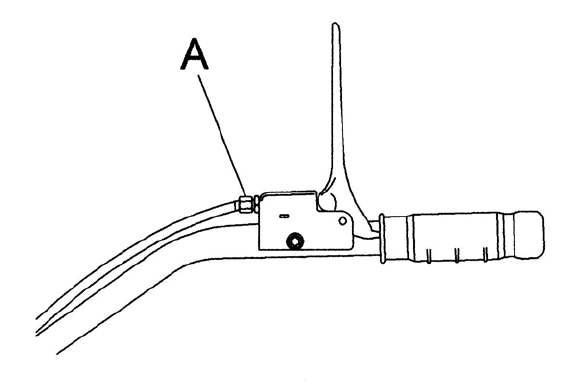

B2) FORWARD CONTROL CABLE

Make sure that there is no play between the upper end of the cable and the adjustment

screw. If there is, or if the cable has stretched, restore to ideal position using the relative

adjustment screw ( Fig. 5, ref. A).

If adjustment using the relative screw proves ineffective, the belts, and hence the engine

mounting, must be adjusted. To perform this operation refer to section 14 C “ BELT

REPLACEMENT AND ADJUSTMENT” of this manual.

Figure 5

C) BELT REPLACEMENT AND ADJUSTMENT

Switch off the engine and disconnect the spark plug wire before carrying out any

maintenance or repair work on the machine.

If a belt is worn or breaks it should be replaced as follows:

- remove the metal guard ( fig. 6 ref. A), by unscrewing and taking out the screws shown

in figure 6 ref. B and C.

C1)BLADE BELT

Disconnect the connecting rod (Fig. 7 Ref. B) by removing the nut and loosening the

screw that secure it to the arm (Fig. 7 Ref. C)

- Once the connecting rod has been disconnected the belt can be slipped off (Fig. 7

Ref. A) by manually turning the relative lower pulley anticlockwise (Fig. 7 Ref. D).

- To fit the new belt follow the procedure in the reverse order.

- Afterwards check that the belt is correctly positioned by using the relative blade control

lever. When this lever is lowered and the belt is at maximum tension, the distance

between the belt and the relative belt guides (Fig. 7 Ref. E) should be approximately 2

mm.

- Then make sure that the belt works properly by tugging lightly on the self-winding

starter cable with the engine switched off and the spark plug wire disconnected. If

everything is working properly the pulley will turn on the engine but will not engage the

belt.

If the belt engages push the engine back slightly towards the rear of the machine (in

the direction of the handlebars) until the belt is in the correct position.