GB - 31

TRACTION DRIVE BELT

REPLACEMENT

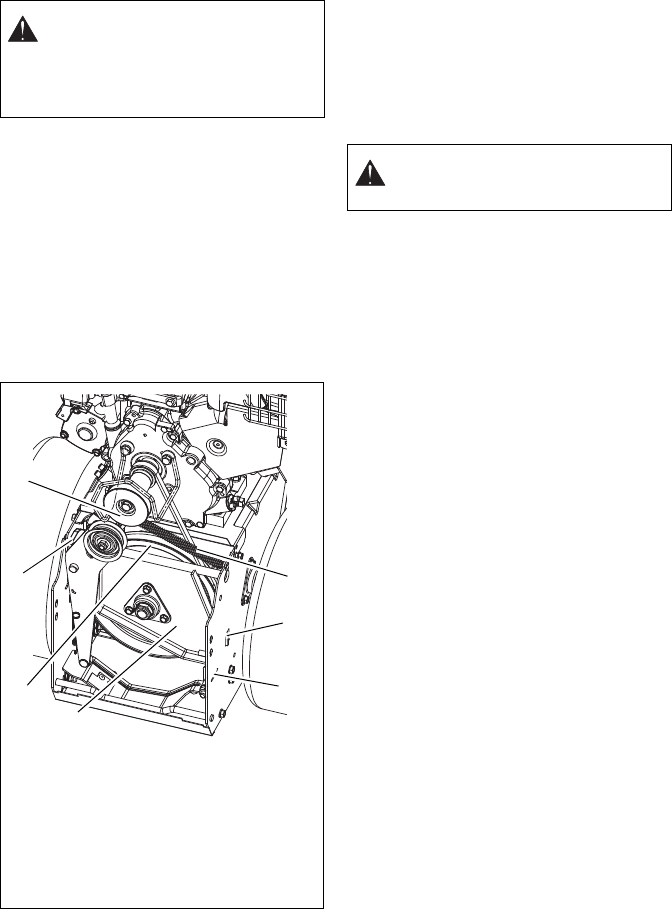

(Figures 38)

NOTE: Housing and frame must be tipped

apart and attachment drive belt removed from

engine sheave in order to change traction

drive belt.

1. Remove attachment drive belt (See

Remove Attachment Drive Belt on

page 29).

2. Remove swing gate spacer.

3. Slide drive plate to the left until finger is

out of the frame.

NOTE: The drive plate is detached to create

space between the drive plate and friction

disc to remove and reinstall the belt.

4. Detach traction idler spring.

5. Remove traction drive belt.

NOTE: To remove belt it may be necessary to

turn crankshaft pulley using recoil starter

handle.

6. Replace traction drive belt.

7. Swing drive plate toward friction disc

and slide finger into stop hole in frame.

8. Reinstall swing gate spacer.

NOTE: Make sure drive plate spring remains

connected to the frame and drive plate.

9. Replace attachment drive belt (See

Replace Attachment Drive Belt on

page 30).

FRICTION DISC REPLACEMENT

Remove Friction Disc

(Figure 39)

1. Shut off engine, remove key, disconnect

spark plug wire and allow unit to cool

completely.

2. Place the unit into the service position

on a level surface.

3. Remove lockpins from wheel axles and

remove wheels.

4. Remove bottom cover by removing six

hex bolts.

5. Disconnect pivot pin from the speed

selector arm. Save the hardware for

reinstallation.

6. Remove spring hairpin nearest drive

gear from hex shaft.

7. Remove left bearing flange from frame.

8. Slide hex shaft to the left to remove the

flat washer, pinion gear and friction disc

assembly from the hex shaft.

NOTE: Be sure to save washers between

bearing and sliding fork for reassembly.

9. Remove friction disc assembly from

frame.

10. Remove three screws holding friction

disc to carrier bearing.

11. Remove old friction disc. Put the new

friction disc in place, cup side to carrier

bearing.

12. Reinstall three screws into new friction

disc and carrier bearing. Torque to

5 – 6 lbf-ft. (6.8 – 8.13 N•m).

CAUTION: Always support Sno-Thro

frame and blower housing when

loosening the cap screws holding

them together. Never loosen cap

screws while unit is in service

position.

Figure 38

1. Swing Gate

2. Swing Gate Spacer

3. Swing Gate Finger & Stop Hole

4. Drive Plate

5. Traction Idler Spring

6. Crankshaft Pulley

7. Drive Plate Spring

4

2

3

5

6

7

1

OS8246

CAUTION: Before tipping unit,

remove enough fuel so that no spills

occur.