GB - 29

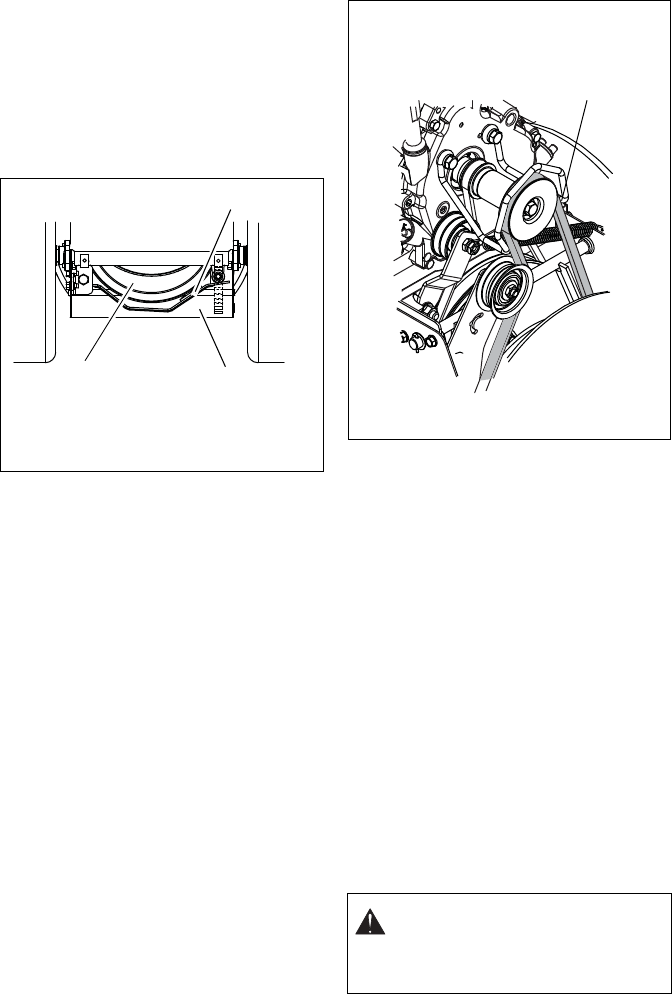

Check Attachment Brake

(Figure 33)

1. With the clutch lever disengaged, brake

pad must contact attachment belt. With

clutch lever engaged, brake pad must be

more than 1/16 in. (1.6 mm) from belt. If

there is more than 1/16 in. (1.6 mm) gap,

go to Check Belt Finger Clearance on

page 29. If there is less than 1/16 in. (1.6

mm) gap, go to Step 2.

2. If there is less than 1/16 in. (1.6 mm)

gap between brake pad and belt, follow

these steps:

a. To increase brake pad gap,

loosen idler adjustment nut, and

move idler away from belt.

Position idler to achieve a 1/16 in.

(1.6 mm) minimum brake pad gap

and a 1/2 – 7/8 in. (12.7 –

22.2 mm) gap between the

plastic roller and the frame.

IMPORTANT: If adjustments cannot be

brought into specified ranges see your Dealer

for repairs.

Check Belt Finger Clearance

(Figure 34)

1. With clutch lever engaged, the belt

finger located opposite the belt idler

must be less than 1/8 in. (3,2 mm) from

belt, but not touching the belt.

To adjust belt finger, loosen the bolts and

move the finger to the proper position.

Tighten the bolts and recheck the belt

finger clearance.

2. Replace the belt cover and tighten

hardware.

ATTACHMENT DRIVE BELT

REPLACEMENT

Remove Attachment Drive Belt

(Figures 35, 36 and 37)

1. Shut off engine, remove key, disconnect

spark plug wire and allow unit to cool

completely.

2. Loosen the hardware securing belt

cover to unit.

NOTE: DO NOT completely remove the

hardware from unit.

3. Remove belt cover.

4. Remove hairpin from chute crank and

separate.

5. 920014 – Remove remote deflector

control cable from dash control.

6. Remove belt finger by removing cap

screws mounting belt finger to engine

(Figure 36 or Figure 37).

7. Remove attachment drive belt from

engine sheave (it may be necessary to

turn engine sheave using recoil starter

handle).

Figure 33

Minimum of 1/16 in. (1.6 mm)

1. Brake Arm and Pad

2. Attachment Pulley

1

2

OS8260

CAUTION: Always support Sno-Thro

frame and housing when loosening

the cap screws holding them

together. Never loosen cap screws

while unit is in service position.

Figure 34

Check belt finger clearance here. With the

attachment clutch engaged, there should

be less than 1/8 in. (3,2 mm) clearance

between the belt and the belt finger. The

belt finger should not touch the belt.

OS8240