GB - 23

CHECK CLUTCH OPERATION

Auger / impeller must stop within 5 seconds

when attachment clutch/impeller brake lever

is released.

Wheels must stop quickly when traction drive

clutch lever is released.

If clutches do not engage or disengage

properly, adjust or repair before operation

(see Attachment Clutch/Brake Adjustment on

page 27 and Attachment Drive Belt

Replacement on page 29).

CLEAN ENGINE

Refer to Engine Manual for detailed

instructions.

CHECK ENGINE OIL

The engine crankcase oil should be checked

every 5 hours of operation. Oil level MUST be

maintained in safe operating range on

dipstick at all times or engine damage will

result (See Engine Manual).

Park unit on a level surface. Refer to Engine

Manual for detailed instructions.

CHANGE ENGINE OIL

Refer to Engine Manual for detailed

instructions.

CHECK TIRE PRESSURE

Keep tires at pressure listed on the tire

sidewall. (see Check Tire Pressure on

page 13).

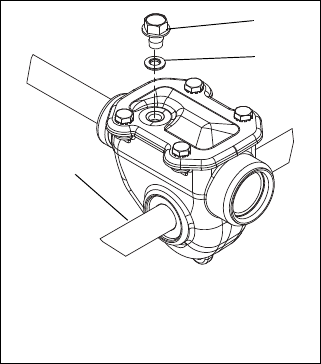

CHECK AUGER GEARCASE

(Figure 20)

IMPORTANT: Proper oil level must be

maintained.

Gear cases are filled to the correct level at

the factory. Unless there is evidence of

leakage, no additional lubricant should be

required. Check oil level each season or

every 25 hours of operation.

IMPORTANT: Be sure unit is resting on a

level surface before checking lubricant levels.

To ensure adequate lubricant level:

1. Remove filler plug and seal washer

(Figure 20). Lubricant must be 1.63 in. –

1.88 in. (4.14 cm – 4.78 cm) from the flat

surface of the inspection cover.

IMPORTANT: DO NOT remove the

inspection cover.

2. Check oil level with suitable dipstick

device. Add lubricant if required.

NOTE: Inspect seal washer for wear or

rubber deterioration and replace as needed.

IMPORTANT: Use only Ariens L3 synthetic

severe duty gear lube (Part Number

00068800). Use of other lubricants will void

unit warranty.

3. Reinstall filler screw and seal washer to

80 lbf-in. (9 N•m).

IMPORTANT: DO NOT OVER-TORQUE!

Note that measurements are in pound force

inches (lbf-in) and NOT pound force

foot (lbf-ft).

IMPORTANT: Be sure to install seal washer

with rubber side down (Figure 20).

IMPORTANT: Improper torquing, omission of

seal washer, or incorrect installation of seal

washer will void unit warranty.

GENERAL LUBRICATION

(Figure 21)

IMPORTANT: Wipe each fitting clean before

and after lubrication.

IMPORTANT: DO NOT allow grease or oil to

get on friction disc, friction plate or belts.

NOTE: Apply Ariens Hi-Temp Grease or

equivalent to the lubrication fittings. See

SERVICE PARTS on page 33.

Sno-Thro should be lubricated (Figure 21) at

beginning of season or every 25 operating

hours.

Auger Shaft

NOTE: To grease auger shaft, remove shear

bolt nuts, and shear bolts. Apply grease at the

grease zerks and then turn the auger

assemblies on the auger shaft. Replace

shear bolts per instructions in Shear Bolts on

page 25.

Figure 20

1. Auger Gearcase

2. Filler Plug

3. Seal Washer

OS8195

2

1

3