MAINTENANCE

A84B 03/07 Maintenance Section 5-7

© 2007 Alamo Group Inc.

MAINTENANCE

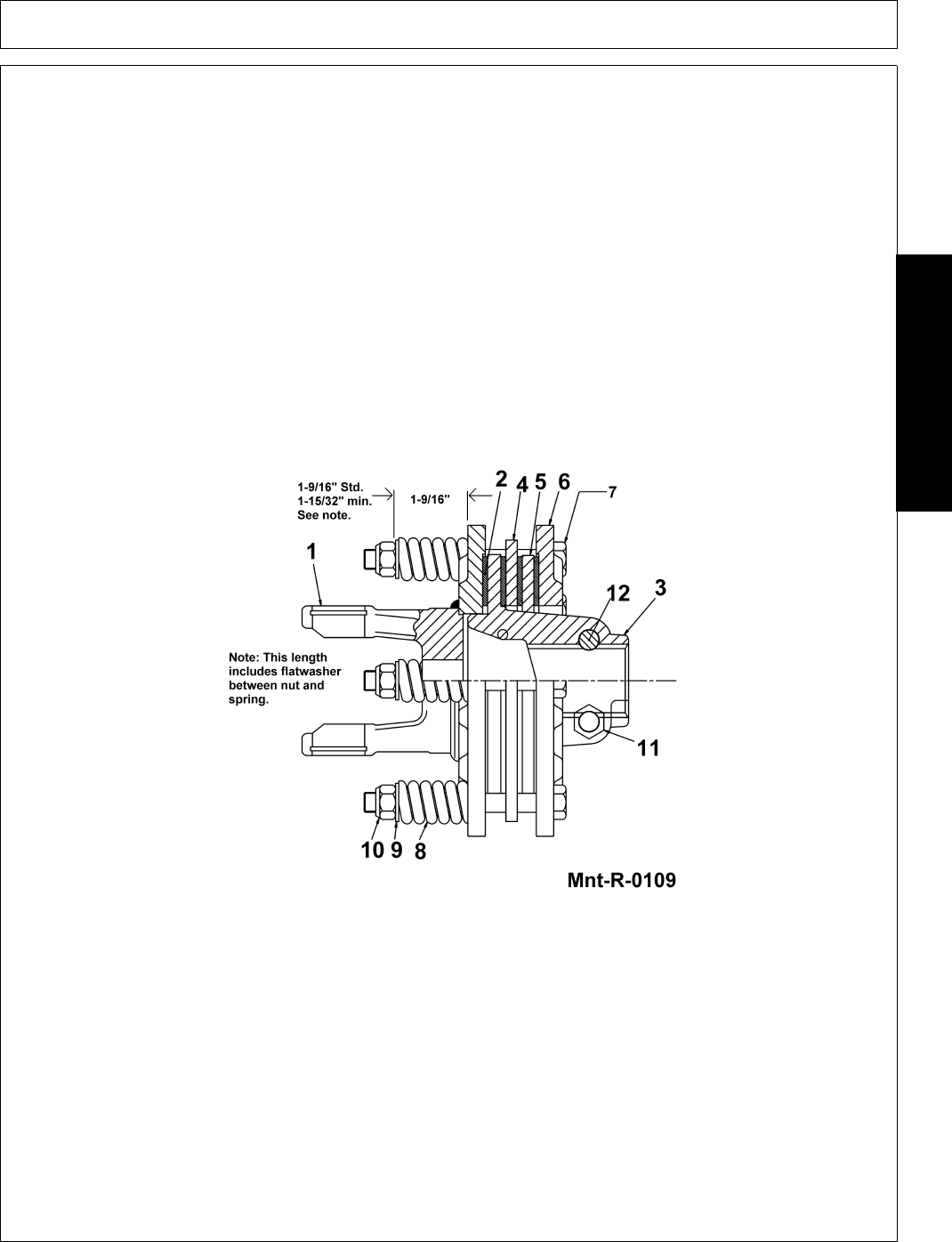

SLIP CLUTCH

A slip clutch is incorporated in the PTO driveline. It is designed to slip, absorb the shock load, and protect the

driveline.

After the first hour of operation, the slip clutch should be checked for overheating. After this first check, the slip

clutch should be checked weekly or anytime there is overheating. To adjust the slip clutch, tighten the spring

bolts to 1-9/16" length. Any increase or decrease in this tightness will change the torque rating and could cause

premature failure.

The slip clutch should be checked periodically and adjusted to compensate for wear. The lining plates are 1/8"

thick when new. Replace after 1/16" wear. If mower has been idle for an extended period of time, or in wet

weather, before operating check to be sure the friction lining plates are not frozen or rusted together. Should

this freezing occur refer to the procedure described in the "Seasonal Clutch Maintenance" section on this page.

Friction lining plate should be checked weekly for oil or grease, wear, and moisture which could cause

corrosion on the drive plates.

SEASONAL CLUTCH MAINTENANCE

It is important the clutch will slip when an obstacle or load heavier than clutch setting is encountered. Before

using the cutter each season, use the following procedure to make sure the clutch will slip and give the

overload protection required.

1. Loosen nuts (#10) FIGURE Mnt-R-0109 until the spring is free and then retighten approximately one

turn.

2. Attach machine to tractor, set engine at approximately half throttle and quickly engage PTO. This

procedure will break clutch facings loose and allow the proper torque to be maintained.

3. Return nuts and bolts to original position. - See Mnt-R-0109.