MAINTENANCE

60C 01/10 Maintenance Section 5-5

© 2010 Alamo Group Inc.

MAINTENANCE

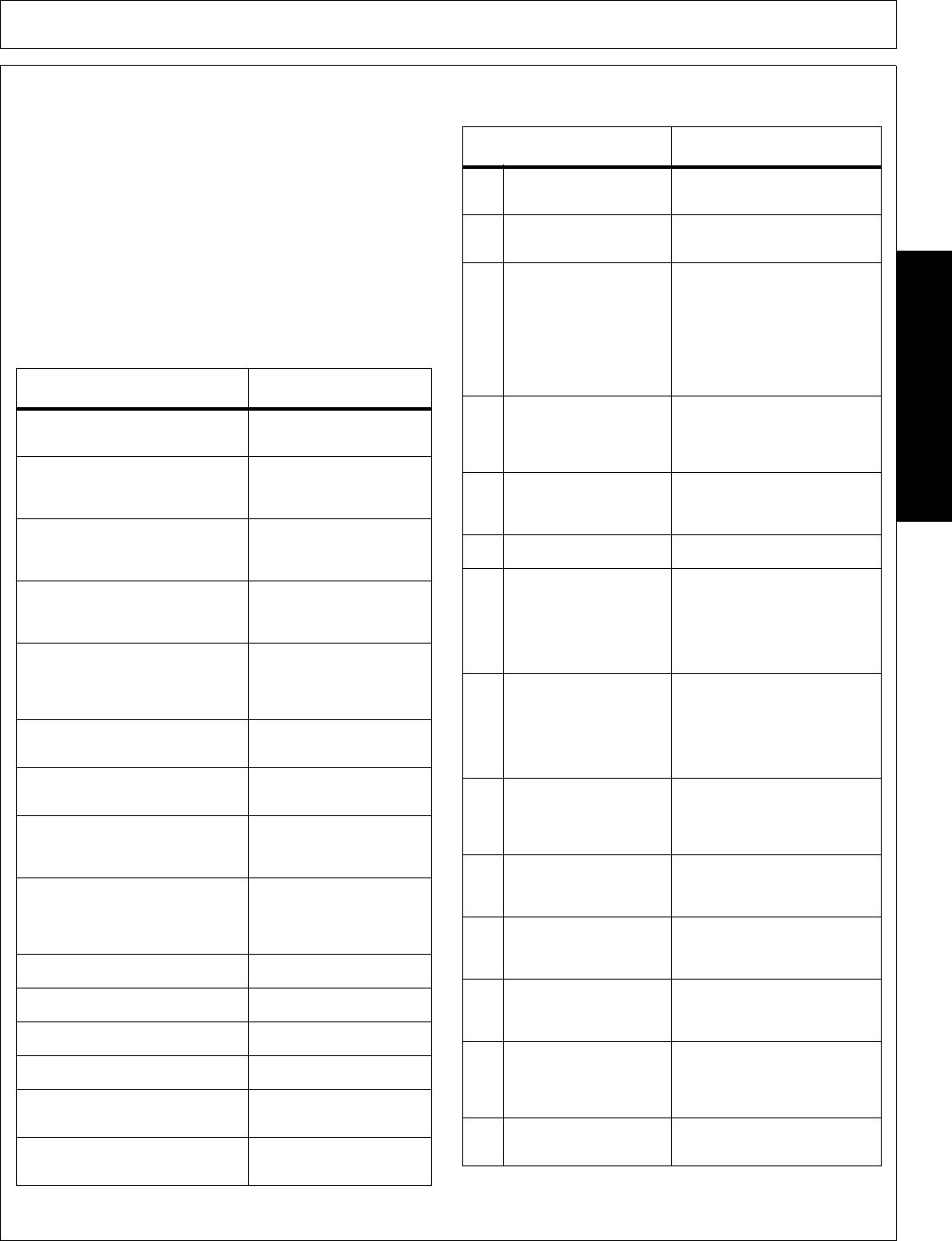

HYDRAULIC TROUBLESHOOTING

Hydraulic troubleshooting material presented in this section

is offered as a guide to diagnosing probable causes and

remedies for general operational problems.

Match your problem wiht the typical problem examples

given in the possible cause column. These numbers

correspond with the possible cause and correction

paragraphs that follow.

NOTE: If, when using the following chart, it is decided that

overhaul of components or pressure adjustment is

necessary, it is recommended that your dealer make these

repairs. He is equipped to do this work.

PROBLEM POSSIBLE CAUSE

Machine fails to operate

when initially started.

1, 2, 5, 7, 15, 23

Machine looses power after

initially operating

satisfactorily.

1, 8, 10, 15, 23

Loss of power in lift or crowd

cylinder, but other cylinders

function properly

22, 24, 28

Loss of power in any one

cylinder including lift and

crowd

8, 9, 10, 11, 12, 13, 22,

23, 25

Loss of power or loss of

cushioning action in swing

cylinders, but other cylinders

function properly.

8, 9, 10, 11, 12, 13, 22,

23, 25

Maximum swing action

cannot be obtained.

12, 14

Slow operation of machine

(lack of power) all cylinders.

1, 4, 6, 15, 23

Spongy or jerky action of

cylinders and/ or noisy

operation.

1, 3, 4, 5

Lift crowd or bucket cylinders

drop under load when lever

spools are shifted from

neutral.

26, 28

Load drops or settles. 8, 10, 13, 25, 26

Leaky cylinders. 10, 11, 12, 13

Leaky valve. 8, 15, 16, 27

Sticky valve spool. 16, 19, 20, 21

Unable to push valve spool

in.

16, 17, 20, 21

Spring centered spools do not

return to neutral.

16, 17, 18, 19, 20, 21

POSSIBLE CAUSE CORRECTIVE ACTION

1 Low oil level in

reservoir.

Fill reservoir to proper

level.

2 No oil supply to

machine.

Engage tractor PTO.

3 Air in system. Purge all circuits of air by

operating all cylinders

through full movements

several times. Check oil in

reservoir for foaming.

Check all suction lines for

leaks. Fill reservoir to

correct level.

4 Oil viscosity too

heavy or oil is not at

operating

temperature.

Use recommended

hydraulic fluid. Run

machine until it reaches

operating temperature.

5 Pump not running. Check PTO to be sure it is

engaged. Pump

connected to PTO.

6 Insufficient pumping. Advance engine throttle.

7 Improper hose

connection.

IMPORTANT: Be sure inlet

and return hoses are

hooked up correctly.

Improper hookup will

result in damage to

backhoe valve.

8 Loose hydraulic

connections, leaks

in fittings or hoses.

Tighten all hose

connections and replace

all damaged o-rings at

leaking o-ring fittings.

Check and replace any

damaged hoses.

9 Restriction in fittings

or hoses.

Check and replace any

damaged hoses and

fittings. Check for pinched

hoses.

10 Oil is bypassing

cylinder piston.

Replace or rebuild

cylinder. Replace

damaged parts.

11 Scored piston rods

or worn rod guides

in cylinder.

Replace or rebuild

cylinder. Replace

damaged parts.

12 Bent piston rod in

cylinder

Replace or rebuild

cylinder. Replace

damaged parts

13 Worn or damaged

rod seals on

cylinder. External

leaks.

Re-pack cylinder. Rebuild

cylinder replacing

damaged parts as

necessary.

14 Swing linkage

jammed.

Remove interference.