44

(1)

MA1

MA2

MA3

MA4

MA5

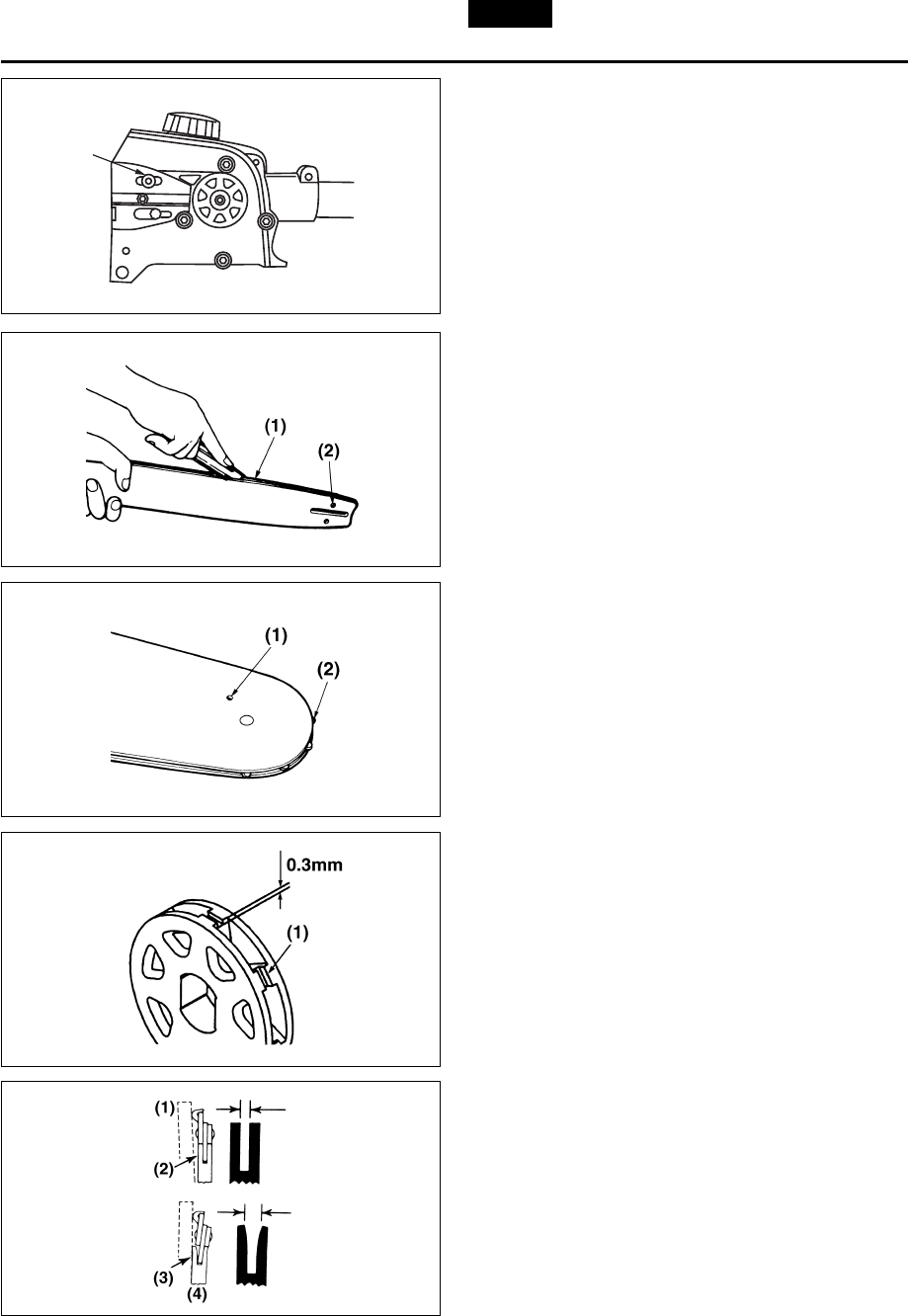

■ OILING PORT

Dismount the guide bar and check the oiling port for

clogging. (MA1)

(1) Oiling port

■ GUIDE BAR

Remove sawdust in the bar groove and the oiling port.

(MA2)

(1) Groove

(2) Oiling port

(Type: Sprocket nose)

Grease the nose sprocket from the feeding port on the

tip of the bar. (MA3)

(1) Grease port

(2) Sprocket

■ OTHERS

Check for fuel leakage and loose fastenings or damage

to major parts, especially housing joints and guide bar

mounting. If any defects are found, make sure to have

them repaired before operating again.

■ SPROCKET

Check for extensive wear, and replace it when the

teeth are worn over 0.3mm. (MA4)

(1) Sprocket

■ GUIDE BAR

The bar rail should always be a square. Check for wear

of the bar rail. Apply a ruler to the bar and the outside

of a cutter. If a gap is observed between them, the rail

is normal. Otherwise, the bar rail is worn. Such a bar

needs to be corrected or replaced.(MA5)

(1) Ruler

(2) Gap

(3) No gap

(4) Chain tilts

9. Maintenance

English