80

9. Maintenance (EX-PS only)

English

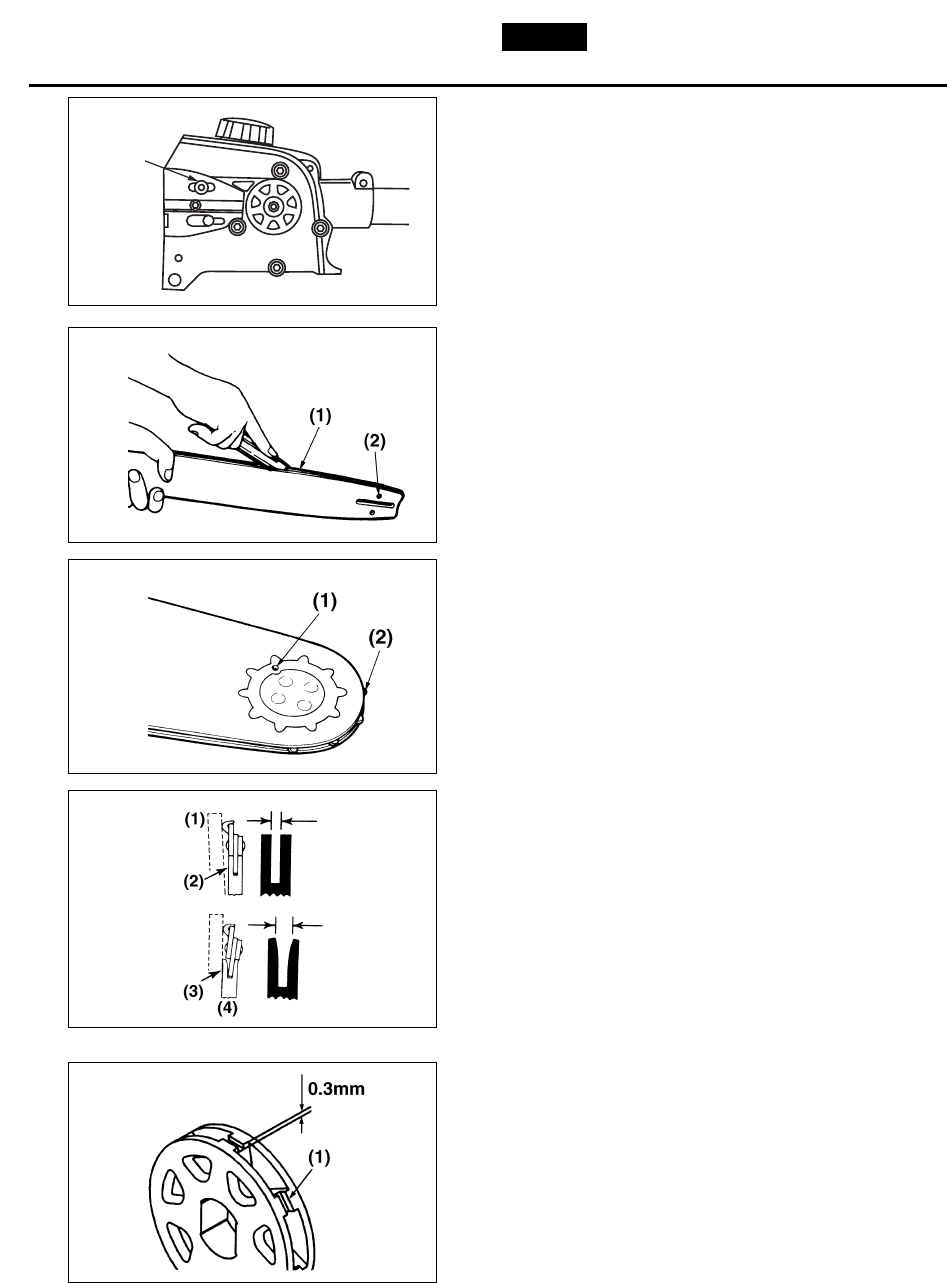

■ OILING PORT

Dismount the guide bar and check the oiling port for

clogging. (MA1)

(1) Oiling port

■ GUIDE BAR

Remove sawdust in the bar groove and the oiling port.

(MA2)

(1) Groove

(2) Oiling port

(Type: Sprocket nose)

Grease the nose sprocket from the feeding port on the

tip of the bar. (MA3)

(1) Grease port

(2) Sprocket

The bar rail should always be a square. Check for wear

of the bar rail. Apply a ruler to the bar and the outside

of a cutter. If a gap is observed between them, the rail

is normal. Otherwise, the bar rail is worn. Such a bar

needs to be corrected or replaced.(MA4)

(1) Ruler

(2) Gap

(3) No gap

(4) Chain tilts

■ SPROCKET

Check for extensive wear, and replace it when the

teeth are worn over 0.3mm. (MA5)

(1) Sprocket

(1)

EX-PS

MA1

EX-PS

MA2

EX-PS

MA3

EX-PS

MA4

EX-PS

MA5