MAYCO C-30HDG PUMP — OPERATION AND PARTS MANUAL — REV. #6 (04/02/12) — PAGE 43

C-30HDG PUMP — MAINTENANCE (PUMP)

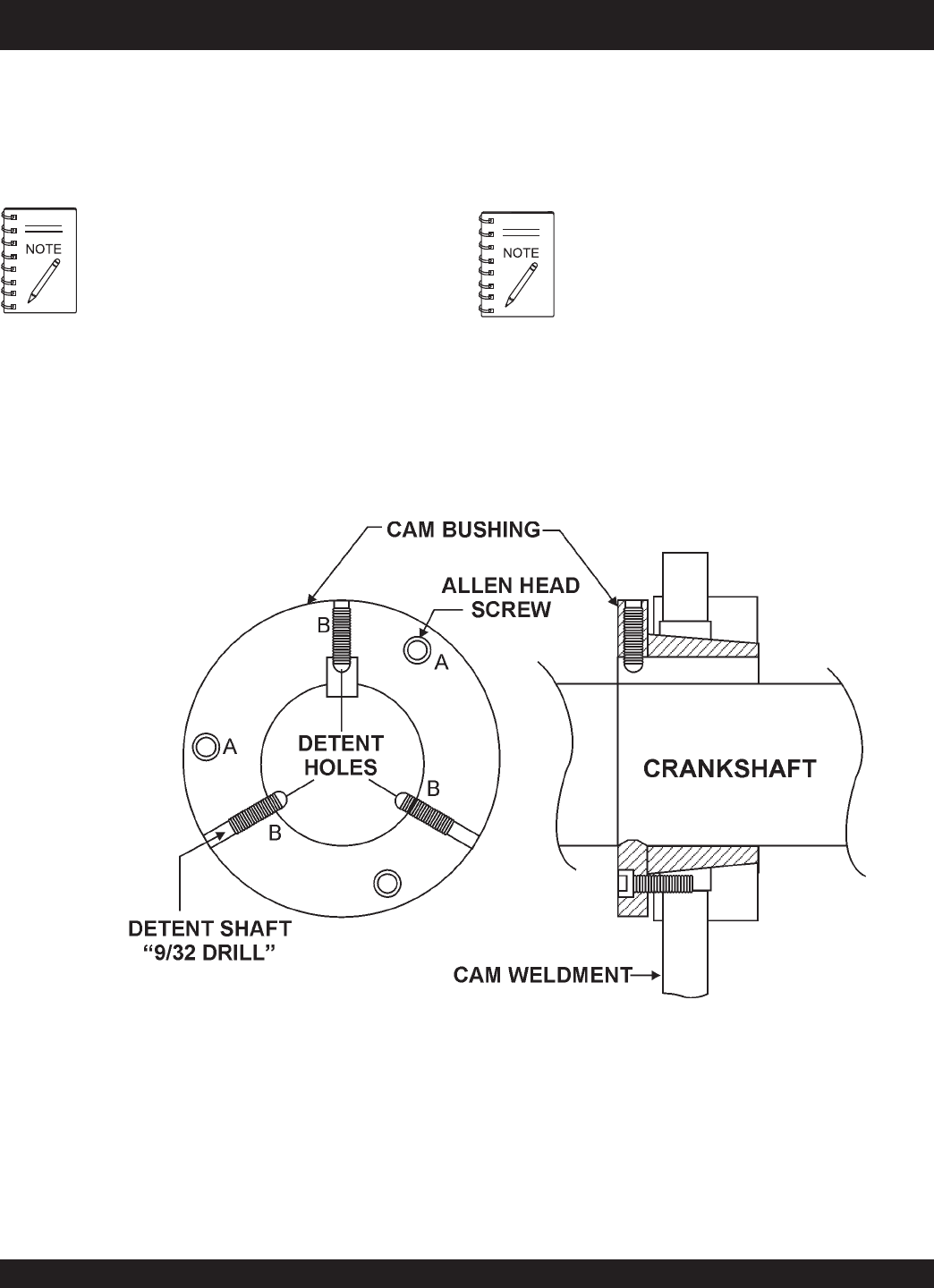

Detent Hole (3) Installation

1. After the bearing assembly has been is installed , remove the

three “dog type” allen head set screws (B) to allow detents to

be drilled. See Figure 25 below.

The detent holes will prevent the bushing from

sliding away from the bearing spacer when the

pump is under load.

2. Use a 9/32” drill to “detent” half (minimum 1/8” deep). Then

“chase” the threads with a 3/8-16 bottom tap and blow out the

chips after drilling, to be certain that the “dog type” allen set

screws bottom in the detents to prevent the taper bushing from

sliding laterally.

3. If this procedure is not followed closely the heavy loading

of the bearing during pumping operation causes the

Timken

™ cone bearings to create lateral forces which will

move the taper bushing and allow the Timken

™ cone

bearings to separate from the race and subsequently fail.

Figure 25. Detent Holes

4. Drill (detent) the shaft under the allen set screws “B” to prevent

the bushing from the sliding away from the bearing spacer

when the pump is under a load.

Position the ‘O’ ring on the O.D. of the bearing

spacer during assembly to assure proper bearing

adjustment.