44

Begin with either side and put the motion control

lever into the neutral position. Adjust the motion

control linkage by rotating the double nuts (D) in

the proper direction until the wheel stops rotating.

See illustration. Move the motion control lever

forward then into the neutral position and place it

into the neutral slot. The wheel must be stopped

completely at this point. Now do the same in

reverse and release the lever. The lever should

return to neutral on its own.

Run engine full throttle to make sure wheels do

not rotate. Readjust if any rotation occurs.

Repeat the whole process for the opposite side

and tighten the nuts against the ball joints.

Turn machine off.

Cutter Housings

Grease housings once weekly or every 40 to 50

hours of use. Use a good synthetic grease. Pump

grease in until a small amount purges from the

popet on the underside of the deck. Check the

torque of the pulley bolt 45 ft/lbs should be

maintained.

Deck Lift Power Unit

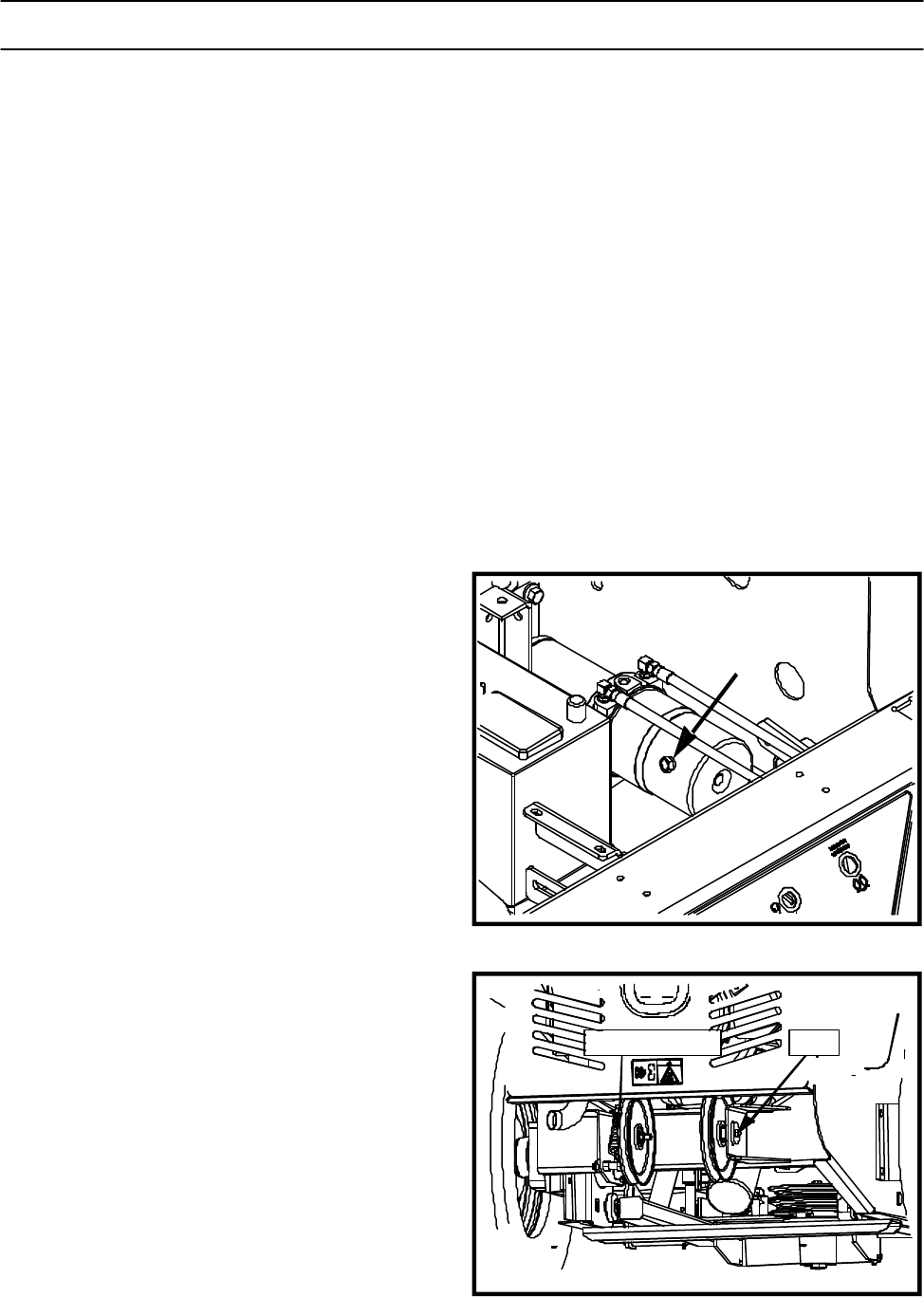

Mule Drive System Adjustment

As the mule drive belt wears and elongates, some

spring tension must be maintained on the left (self-

adjusting) mule drive idler.

For best performance, occasionally adjust the right

(fixed) mule drive idler position in the slot so central

axis of idler pulleys align.

MAINTENANCE

Deck Lift Power Unit Vent Plug

Mule Drive Adjustment

SELF-ADJUSTING FIXED

The system is pre-filled and factory sealed. In the

event it becomes necessary to replace oil in the

reservoir, the cylinder or cylinders must be in the

retracted position. Carefully remove all dirt and

debris from around the fill plug and remove the

plug. Fill to the lower edge of the hole with 15W-50

synthetic oil and replace the plug firmly to reseal

the system.