10

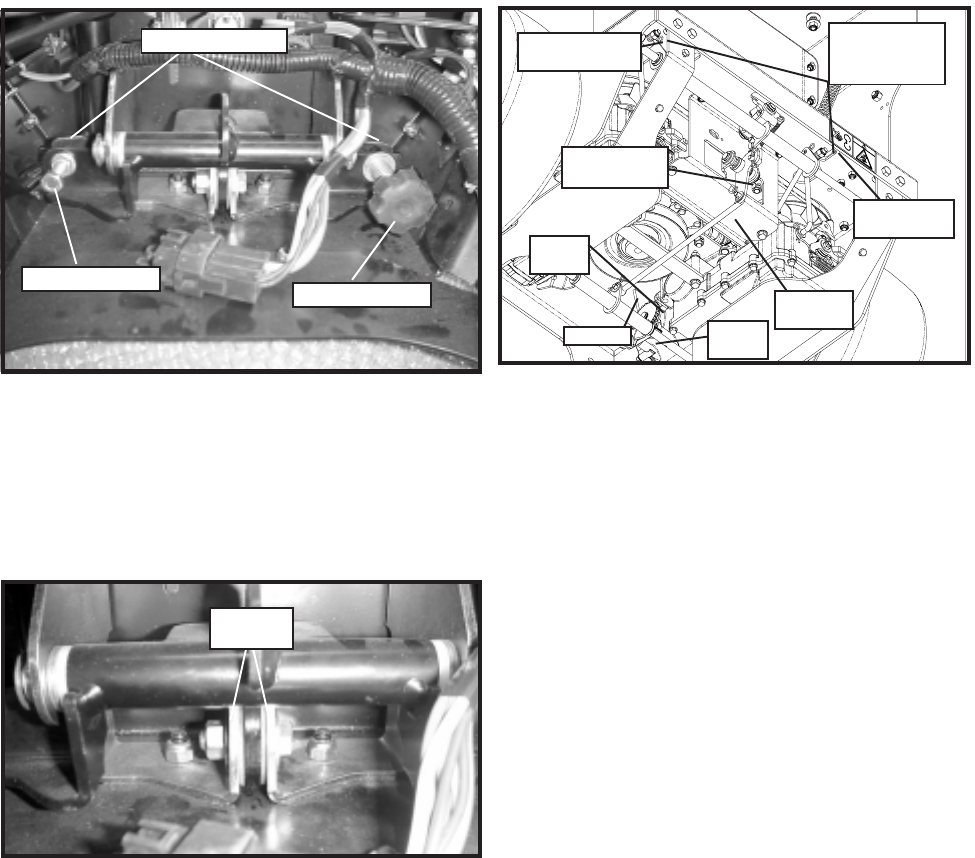

FIGURE 7

BYPASS ADJUSTMENT

If the mower will not free wheel with the brake/by-

pass lever in the bypass position, an adjustment

may be needed. Jack up the rear of the unit and

secure with jack stands. Remove the rear guard

on the back of the rear deck. (See Figure 7.) Place

the brake/bypass lever in the brake position. Us-

ing a 1/2” wrench, tighten the nyloc nut on the by-

pass linkage until the compression spring is fully

compressed. Move the brake/bypass lever into the

bypass position. Check the tires to verify that they

will turn. If they still will not turn, a brake adjust-

ment may be required. (See Brake Adjustment.)

NOTE: IF THE BYPASS ADJUSTMENT IS

MADE WITH THE BRAKE BYPASS LEVER IN

THE BYPASS POSITION, THE BRAKE POSI-

TION MAY NOT BE OBTAINABLE.

COMPRESSION

SPRING

BYPASS

ADJUSTMENT

NUTS

BRAKE

BELLCRANK

IZT BYPASS

LINKAGE

BRAKE

LINKAGE

BRAKE

COG

BRAKE

ARM

SWIVEL

SET-UP

GROUND SPEED LEVER FRICTION

The ground speed lever has friction washers to

adjust the tension of the lever. To adjust, use two

9/16” wrenches and tighten or loosen the bolt and

nut on each side of the friction plate. See Figure 6.

FIGURE 6

BRAKE ADJUSTMENT

Jack up the rear of the unit and secure with jack

stands. Remove the rear guard on the back of the

rear deck. Remove the hairpin and washer from

the rear of the brake linkage. See Figure 7. Place

the brake/bypass lever in the brake position. Pull

back on the brake linkage. Verify that the IZT brake

arms are fully seated in the brake cogs. (The tires

may need to be rotated slightly to seat the brakes.)

Turn the linkage in the swivel until the linkage just

slides in the hole in the brake bell crank. Replace

the washer and hairpin. Verify that the brakes en-

gage.

TRACKING BOLT

TRACKING PLATE

TRACKING KNOB

FIGURE 5

FRICTION

PLATES

INTERLOCK SAFETY SYSTEM

The interlock modules function is to prevent the

engine from starting if the blades are engaged and/

or the driver levers are not locked in the thumb

latches. It also causes engine shutdown if the op-

erator removes hands, or attempts to leave the

operator position while the blades are engaged or

the drive levers are not locked in the thumb latches.

After the engine starts, the operator must hold ei-

ther the left or right O.P. lever down before engag-

ing the blades or unlocking the thumb latches. If

neither O.P. lever is held, the engine will kill. Check

the function of the safety electrical system on a

regular basis.