Dealer Service 25

MAN0475 (9/21/2005)

with an OD that will sit on the outside edge of the

seal but will clear the housing. Tubing with an OD

that is too small will bow seal cage and ruin seal.

5. Carefully press seal into housing, avoiding

distortion to the metal seal cage.

Figure 19. Seal Installation

Vertical Shaft Seal Replacement

1. Disconnect and remove the driveline from the

gearbox.

2. Remove vent plug (24). Figure 18, and siphon gear

lube from housing through this opening.

3. Remove gearbox stand from mower deck.

4. Remove gearbox and pulley from gearbox stand.

5. Remove vertical shaft seal (18). Replace with new

seal (see Seal Replacement, page 24).

Vertical seal should be recessed in housing.

NOTE:Distortion to seal cage or damage to seal lip

will cause seal to leak.

6. Fill gearbox with SAE 80W or 90W gear lube until it

runs out the level plug.

7. Assemble gearbox and pulley to gearbox stand.

Attach gearbox stand to mower deck.

Horizontal Shaft Seal Replacement

1. Disconnect and remove the driveline from the

gearbox.

2. Remove vent plug (24), Figure 18, and siphon gear

lube from housing through this opening.

3. If the leak occurred at either end of horizontal shaft,

remove oil cap (20) and/or oil seal (19). Replace

with new one (see Seal Replacement, page 24).

Horizontal seal should be pressed flush with out-

side of housing.

4. Fill gearbox with SAE 80W or 90W gear lube until it

runs out the level plug

Gearbox Removal from Mower

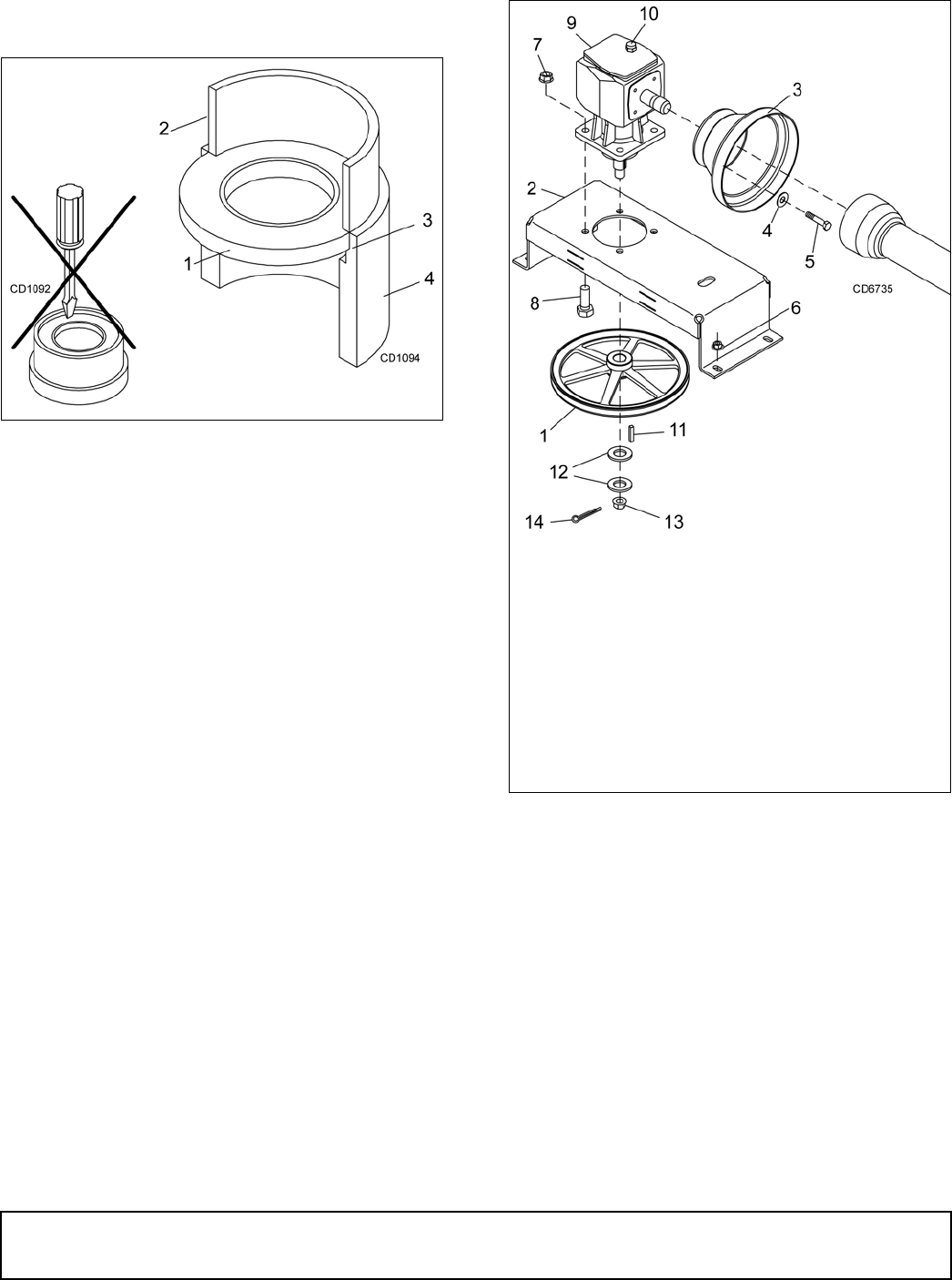

Refer to Figure 20.

Figure 20. Gearbox Stand Assembly

1. Disconnect and remove the rear driveline from the

gearbox (9).

2. Remove vent plug (10) and siphon gear lube from

housing through this opening.

3. Remove gearbox stand (2) from mower deck by

removing four flanged lock nuts (6).

4. Remove four cap screws (5) and washers (4) and

remove shield (3) from gearbox.

5. Remove castle nut (13) and hardware from output

shaft of gearbox.

6. Remove sheave (1) from gearbox.

7. Remove four bolts (8) that attach gearbox to

gearbox stand and remove gearbox.

1. Seal

2. Pipe or tube

3. Seal seat

4. Casting

Pipe or tube

must press at

outer

edge of

Incorrect

Installation

6. Nut, flanged lock 1/2 NC

7. Nut, flanged lock 5/8 NC

8. Screw, HHCS 5/8 NC x 1-3/4

9. Gearbox

10. Vent plug

11. Key, 1/4 x 1/4 x 1-1/4

12. Washer, 25 x 44 x 4 mm

13. Castle nut, M24 x 2

14. Cotter pin, 3/16 x 2

1. Sheave, offset 13.25 PD

2. Gearbox stand

3. Shield

4. Washer, flat 5/16

5. Screw, HHCS 8 mm x

1.25P x 16 mm