32 Assembly

MAN0670 (Rev. 6/27/2008)

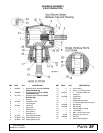

DISASSEMBLE SHIPPING UNIT

Remove all parts that are wired and strapped to cutter.

Remove cap screws (5) and flange lock nuts (6) that

are securing tailwheel bracket (2) to the tailwheel

bracket mounting holes (A).

ASSEMBLE CUTTER

1. Attach tailwheel bracket (2) to cutter on the inside

of tailwheel pivot holes (A) using cap screw (5) and

flange lock nut (6) previously removed. Tighten

hardware finger tight.

NOTE: Make sure grease fitting on tube is on top

when installing tailwheel.

2. Select desired height adjustment holes (4), and

secure tailwheel bracket with cap screws (9) and

flange lock nuts (10). Cutting height adjustment will

be necessary when cutter is fully assembled. See

page 16.

3. Loosen hitch pins, rotate A-frame bars (11) up and

align diagonal brace bars (1) with tailwheel pivot

holes (A) and the inside of tailwheel bracket (2).

Secure using cap screw (5) and flange lock nut (6)

previously installed.

4. Disassemble clevis and A-Frame bars and attach

diagonal braces to the outside of A-Frame bars.

Secure all bars, clevis and sleeve with previously

used hardware.

5. Tighten all hardware on cutter.

6. Raise rear of cutter and insert tailwheel assembly

(3) into tailwheel bracket (2). Secure with washer

(8) and spiral pin (7).

Figure 29. Tailwheel Installation

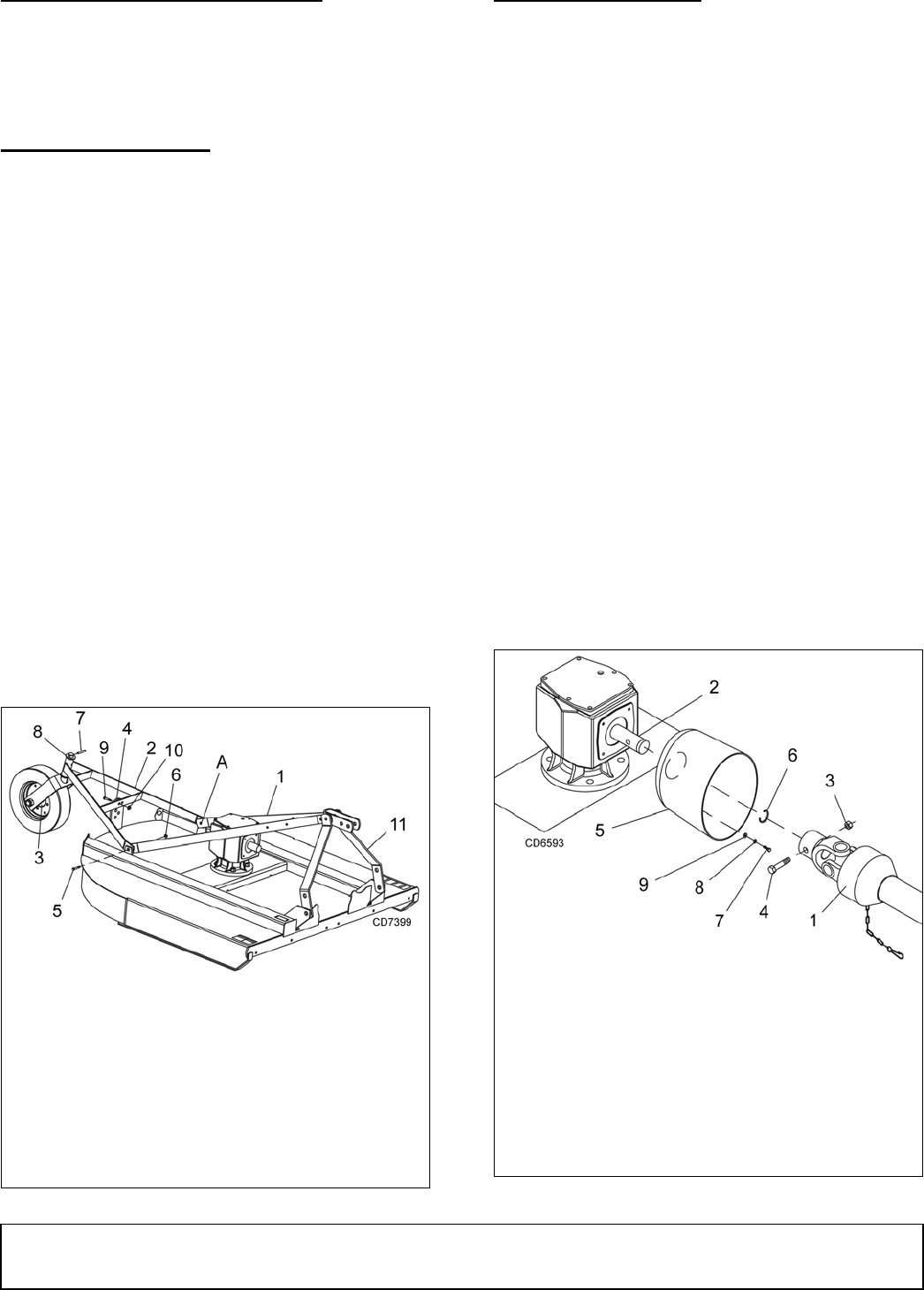

INSTALL DRIVELINE

Select either the standard shear bolt or optional slip

clutch driveline.

Shear Bolt Driveline

NOTICE

■ A grade 2 bolt must be used for the shear bolt to

provide gearbox protection.

1. Position clutch shield (5) against gearbox. Secure

using cap screw (7), lock washers (8), and flat

washers (9). Torque hardware to 12 lbs-ft.

2. To prevent seal damage, carefully push driveline

onto gearbox input shaft until it contacts the

gearbox housing.

3. Place retaining ring (6) in slot on input shaft and

snap into place.

4. Align the holes in the driveline yoke and gearbox

input shaft. Install and tighten shear bolt (4) and

nut (3).

5. Lubricate rear driveline half and install front

driveline half.

6. Attach tether chain (if equipped) to clutch shield

(5).

Figure 30. Shear Bolt Driveline Assembly

1. Diagonal brace

2. Tailwheel bracket

3. Tailwheel

4. Height adjustment

5. 1/2 NC x 2 HHCS

6. 1/2 NC Flange lock

washer

7. Spiral pin

8. Flat washer, 33 mm

9. 1/2 NC x 1-1/2

HHCS

10. 1/2 NC Flange lock

nut

11. A-Frame bar

A. Diagonal brace &

Tailwheel bracket

mounting hole

1. Driveline shield

2. Input shaft

3. 1/2 NC Lock nut

4. 1/2 NC x 3 Cap screw GR2 (Shear Bolt)

5. Clutch shield

6. Retaining ring

7. M8 x 1.25P x 20 mm Cap screw

8. 5/16 Lock washer

9. 5/16 Flat washer

* Items 3, 4, & 6 are in manual tube.