Operation 13

MAN0670 (11/16/2007)

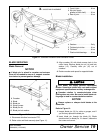

Top Link Adjustment

Figure 2. Top Link Adjustment

1. Attach tractor top link (1) to lowest hole provided in

the tractor’s top link bracket (6).

2. Attach rear portion of tractor top link to the first hole

on the cutter floating link (3). Select a top link

mounting pin that will allow the floating link to

swing freely through the cutter A-frame bars (5).

3. Raise cutter to transport position and adjust tractor

top link until cutter is level in the raised position.

NOTE: If you cannot level the cutter using the low-

est hole in the tractor’s top link bracket, move top

link to the next hole and level the cutter.

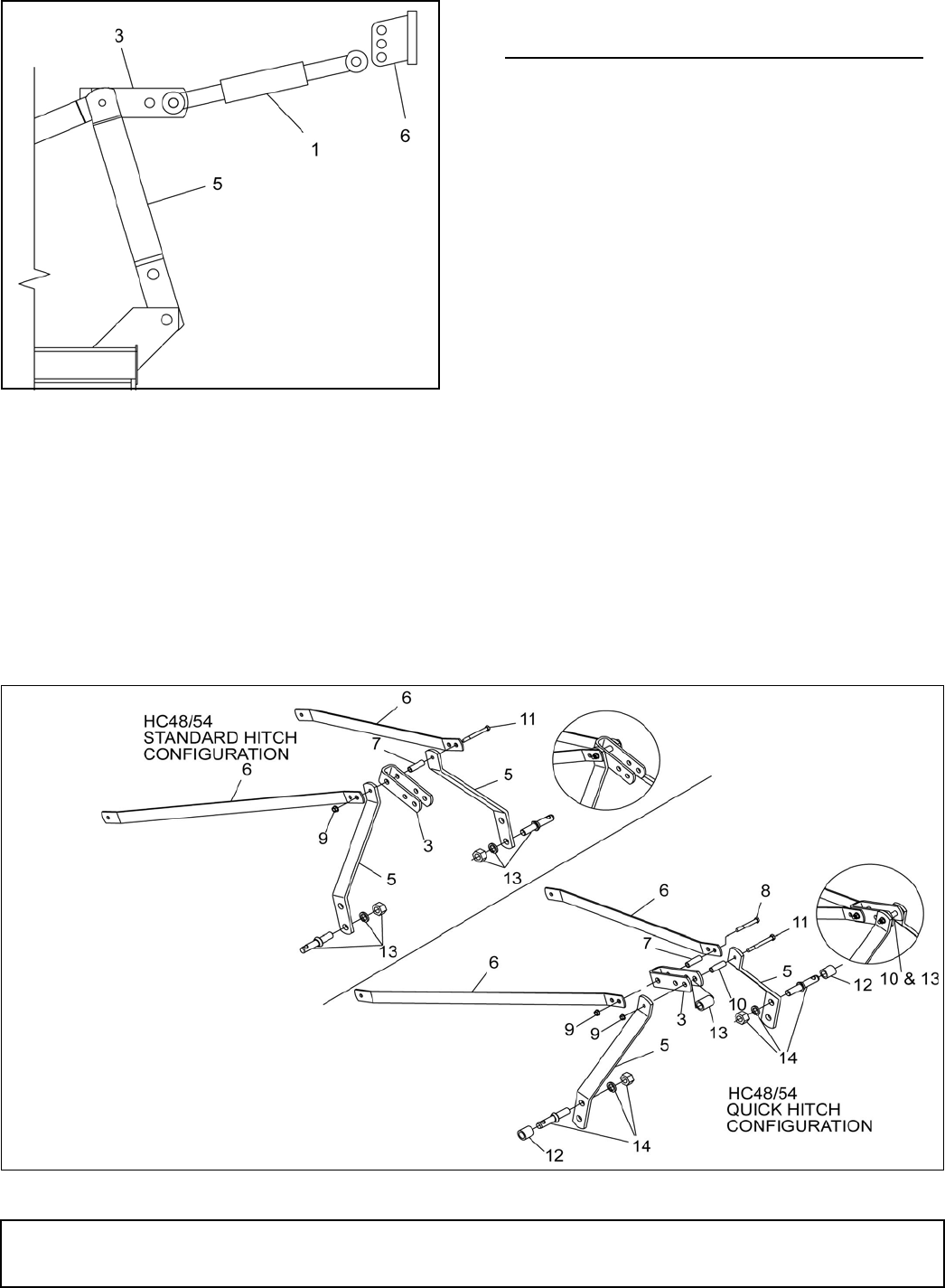

QUICK HITCH ASSEMBLY (HC48 / HC54)

Refer to Figure 3

1. Remove brace arms (6), floating link (3), cap screw

(11), spacer (7), and flange lock nut (9) from hole

on top of A-frame bars (5).

2. Remove hitch pins and place A-frame bars (5) in

second holes. Install hitch pins and tighten at this

time.

3. Attach open end of floating link (3) to hole in A-

frame bars (5) and secure using cap screw (11),

sleeve (10), and flange lock nut (9).

4. Attach closed end of floating link (3) to first hole in

diagonal braces (6), use second hole for sub-

compact tractors. Secure using cap screw (8),

spacer (7), and flange lock nut (9) supplied in

hardware bag. Tighten all hardware and hitch pins.

NOTE: Top hook on quick hitch will pick up on

sleeve (10). Bottom quick hitch hooks will attach to

cutter hitch pins. Category I hitch pins will require

bushings (PN 38214) to be installed over hitch pins

before connection to quick hitch.

5. Install sleeve (12) over hitch pins and secure with

klick pin before connecting to quick hitch.

6. Raise cutter to transport position and adjust tractor

top link until cutter is level in the raised position.

Figure 3. Standard Hitch and Quick Hitch Configurations - HC48, HC54

1. Tractor top link

3. Floating link

5. A-Frame bars

6. Tractor top link bracket

3. Floating link

5. A-frame

6. Lift bars

7. 1/2 x 2-3/4 Spacer

8. 1/2 NC x 4 Cap screw

9. 1/2 NC Flange lock nut

10. 1/2 x 3/4 x 2-13/16 Sleeve

11. 1/2 NC x 5 Cap screw

12. .91 x 1.44 x 1.25 Sleeve

13. Cat 1 Mounting pin with

hardware

(Rev. 7/4/2008)