Operation 15

MAN0670 (11/16/2007)

DRIVELINE INSTALLATION (TRACTOR

PTO)

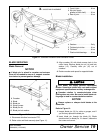

Make sure spring-activated locking pin or collar

slides freely and is seated firmly in tractor PTO

spline groove.

To Install:

Pull locking collar back and at the same time push the

driveline onto tractor PTO shaft until locking device

engages.

To Remove:

Hold driveline into position, pull locking collar back, and

slide driveline off tractor PTO shaft.

Figure 5. Lock Collar

DRIVELINE ADJUSTMENT

Attach the cutter to the tractor 3-point hitch (or quick

hitch if available). Do not attach driveline. Raise and

lower cutter to determine maximum and minimum dis-

tance between the tractor PTO shaft and the gearbox

input shaft. If the distance is too large, the driveline will

be too short for proper engagement. If distance is too

small, the driveline may bottom out in operation

and damage the cutter or tractor.

The driveline length must be sufficient to provide at

least 1/3 driveline length of engagement during normal

operation. There must be at least 4 inches of engage-

ment at the cutter’s lowest possible point of operation.

Driveline must not bottom out when raised to the maxi-

mum height possible.

If driveline is too short, please call your Woods dealer

for a longer driveline.

If driveline is too long, please follow the instructions for

shortening the driveline.

SHORTEN DRIVELINE

1. Move cutter up and down to get the shortest

possible distance between tractor PTO shaft and

gearbox input shaft.

2. Separate driveline into two halves and connect

them to the tractor PTO and gearbox.

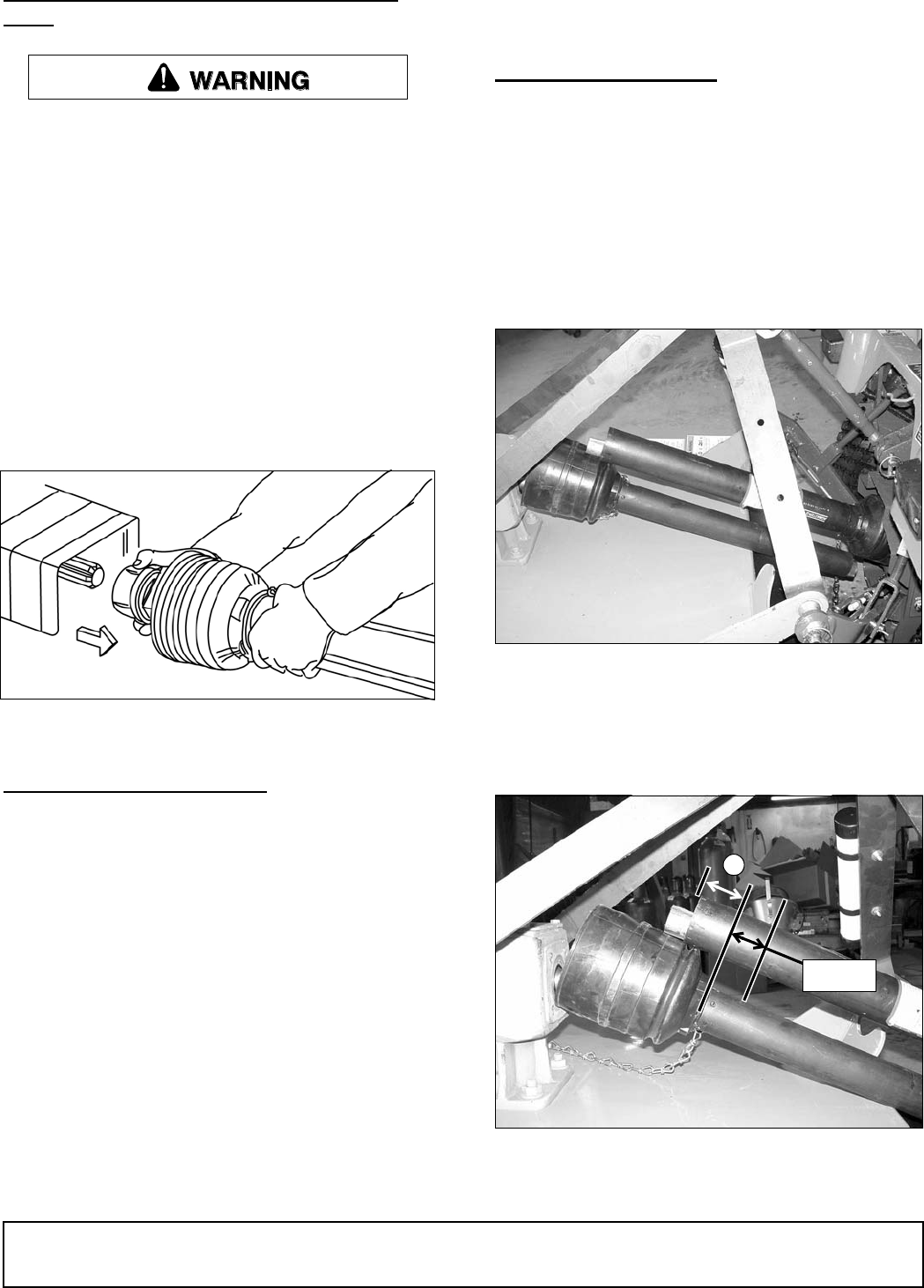

3. Place driveline halves parallel to one another to

determine how much to shorten the driveline.

Figure 6. Drive Halves Placed Parallel

4. Measure from end of the upper shield to the base

of the bell on the lower shield (A). Add 1-9/16" to

dimension (A). See Figure 7.

Figure 7. Determine Shield Length

5. Cut the shield to the overall dimension.

DP2

1-9/16"

A

DP3