Assembly 43

MAN0390 (Rev. 4/6/2007)

ASSEMBLE - DS96 MOUNTED CUTTER

Refer to Figure 39.

Place jackstands under cutter to raise it off the ground

to provide clearance when assembling cutter. See

“BLOCKING METHOD” on page 21 for jackstand

placement.

Install A-Frame

1. Attach front A-frame bars (3) to the top of the cutter

mast plates using hitch pins (4), bushing sleeves

(11), washers (41), slotted hex nuts (42), and cotter

pins (39).

2. Torque hex nuts to 400 lbs-ft.

Refer to Figure 37 and Figure 39

3. Attach rear A-frame bars (2) to the mounting lugs

on the rear of the cutter using cap screws (31) and

lock nuts (32).

4. Attach the two rear A-frame bars together at the

top rear hole using cap screw (33), spacer sleeve

(9), and lock nut (32).

5. Place both break links (7) together and position

between front hole of rear A-frame bars. Secure

rear A-frame bars and break links together using

cap screw (33), pacer sleeve (9), and lock nut (32).

NOTE: Break links must rest on top of rear spacer

sleeve (9).

6. Place spacer sleeve (6) through front holes of

break links. Align break links with bottom holes on

front A-frame bars (3) and secure together using

cap screw (37) and lock nut (38).

7. Install top link pin (10) and sleeve (8) into top holes

of A-frame. Secure with cotter pin (39) and klik pin

(40). Sleeve (8) is used with category 2 top links.

Figure 37. Break Linkage Installation

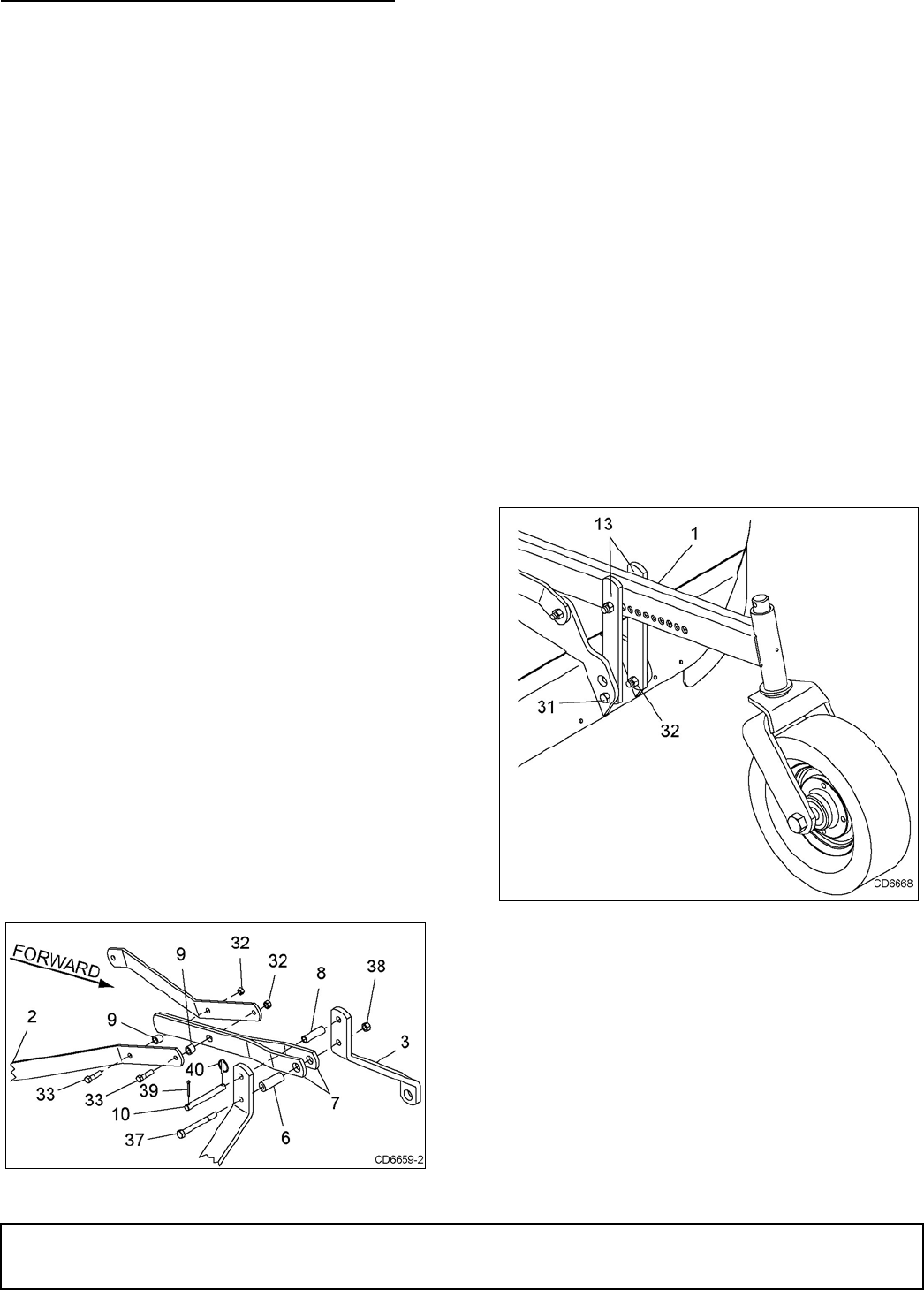

Install Tailwheel Arms

Refer to Figure 38 and Figure 39.

1. Attach adjustment arms (13) to lower holes of lugs

on the rear of the cutter. Braces must be placed on

the inside of mounting lugs (Figure 38).

2. Secure each adjustment brace with a cap screw

(31) and lock nut (32).

3. Attach tailwheel arms (1) between deck rail and lug

near the middle of the cutter. Secure into position

using cap screws (30), two washers (12), and lock

nut (32). NOTE: See Figure 39 for washers (12)

placement.

4. Align holes on adjustment arms (13) with a hole in

the tailwheel arm and insert cap screw (30).

Secure with lock nut (32). NOTE: Hole positions in

tailwheel arms determines cutting height. Final

adjustment will be necessary when cutter is

mounted to the tractor.

Figure 38. Adjustment Arm Installation

Install Driveline

1. Coat input shaft of gearbox with a light coating of

grease.

2. Attach slip clutch on driveline (5) to input shaft of

gearbox. Tighten cap screws (35) and lock nut

(36).

3. Attach rear tether chain of driveline to driveline

shield.

1. Tailwheel arm

13. Tailwheel adjustment arm

31. 5/8 NC x 4-1/2 Cap screw

32. 5/8 NC Lock nut