Hydraulic Installation 9

MAN0530 (6/30/2006)

1014620 HOSE KIT INSTALLATION

Keep hands and body away from pressurized

lines. Use paper or cardboard, not hands or other

body parts to check for leaks. Wear safety goggles.

Hydraulic fluid under pressure can easily penetrate

skin and will cause serious injury or death.

Make sure that all operating and service person-

nel know that if hydraulic fluid penetrates skin, it

must be surgically removed as soon as possible by

a doctor familiar with this form of injury or gan-

grene, serious injury, or death will result. CON-

TACT A PHYSICIAN IMMEDIATELY IF FLUID

ENTERS SKIN OR EYES. DO NOT DELAY.

Air in hydraulic systems can cause erratic oper-

ation and allows loads or equipment components

to drop unexpectedly. When connecting equipment

or hoses or performing any hydraulic maintenance,

purge any air in hydraulic system by operating all

hydraulic functions several times. Do this before

putting into service or allowing anyone to

approach the equipment.

Protective hose sleeves must cover all hydrau-

lic hoses within 20 inches of the operator and be

secured onto metal hose fittings. Replace hoses or

sleeves if damaged or if protective sleeve cannot

be properly positioned or secured.

Make sure all hydraulic hoses, fittings, and

valves are in good condition and not leaking before

starting power unit or using equipment. Check and

route hoses carefully to prevent damage. Hoses

must not be twisted, bent sharply, kinked, frayed,

pinched, or come into contact with any moving

parts. Operate moveable components through full

operational range to check clearances. Replace

any damaged hoses immediately.

IMPORTANT

■ If hydraulic lines are not connected as shown in

this manual, the control valve may be damaged. A

blocked outlet (RETURN) or improper hose

connection will cause pressurized oil to enter the

return circuit and damage the valve.

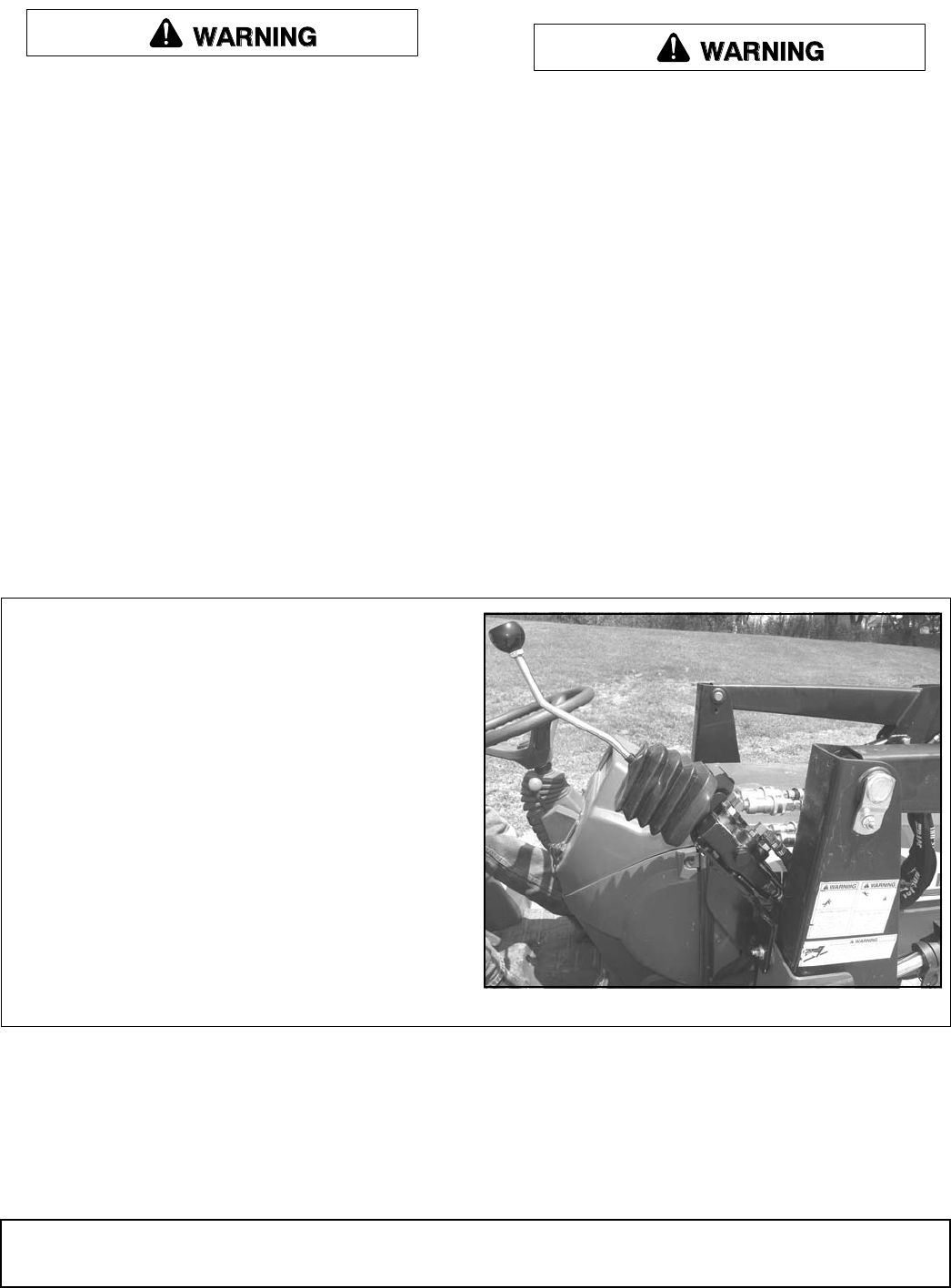

General Description

Completion of this hose kit installation requires con-

nection to a Woods single-lever control valve,

mounted to the right loader mount with a mounting

bracket as shown in Figure 14.

Mount control valve to loader mount before proceed-

ing.

Figure 14. Single-Lever Control Valve

DP8