16 unigreen

4.13 WASHING THE ATOMISER

After every treatment, thoroughly clean the equipment, washing it with water

inside and out. Dirty equipment is very dangerous for people and in particular

for children.

Discharging the residues of washing in the environment without taking

precautions is forbidden as this pollutes water courses. Distribute the

residues on the field or the crops where they won’t cause any damage.

WARNING: the indications to follow for using chemical products are indicated

in paragraph 2.2.1.

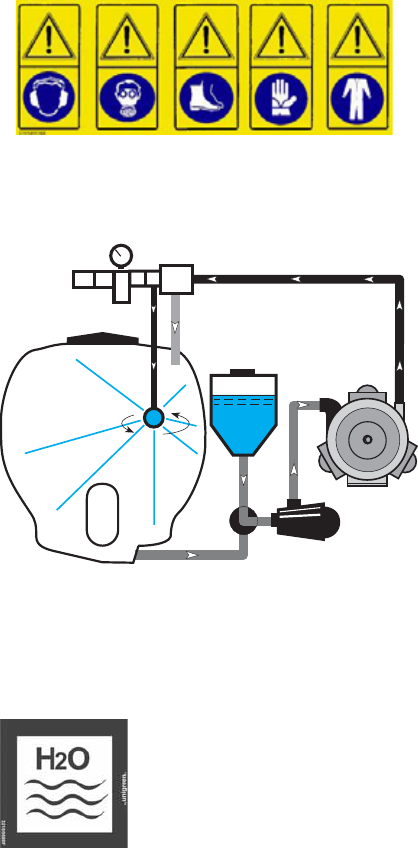

4.13.1CIRCUIT WASHER AND TANK WASHER

Some machine models are fitted with a circuit washer tank (FIG.17). This

tank must be filled with clean water and used to rinse the entire circuit

including the suction, delivery, pump, pressure regulator, jets and nozzles.

Thanks to the practical rotary nozzle it also rinses the inside surfaces of the

tank.

NB: To completely clean the tank and the pipes of any residues of the various

active principles, we recommend adding 2kg of soda to the washing liquid for

every 100 L of water.

At the end of the treatment, wash the circuit and the tank.

a) Stop the diaphragm pump disengaging the power-takeoff.

b) Check you have filled the circuit washer tank (C).

c) Make sure the main control of the pressure regulator is OFF and that all

the boom sectors are closed.

d) Turn suction deviator A to the circuit washer position (H2O).

e) Start the diaphragm pump by engaging the power-takeoff.

f) Increase the engine speed until all of the liquid in circuit washer tank C

has been sucked up.

g) Turn the diaphragm pump off and turn deviator A to the work position

(TANK).

h) Turn the main control to ON, so there is pressure in the circuit.

i) Start the diaphragm pump again and use the tank washing tap on the

regulator (or on pump P) that supplies jet B.

j) After a few minutes you can close the tank washing tap

k) Distribute the washing residues over a portion of the field where it won’t

cause damage.

l) After you have finished washing, stop the diaphragm pump.

NB: at the end of the washing cycle, if there is the risk of frost, pour roughly

500 grams of normal antifreeze for auto vehicles into the tank.

FIG. 16

A

B

C

F

P

This symbol identifies

the clean water tank

on the machine used

to wash the circuit

WARNING: using the taps on the pump or in any

case on the front of the machine puts the operator

near the cardan shaft. Despite the presence of CE

standard protective covers you should take great

care.