unigreen 7

Refer to the enclosed handbooks for the use and maintenance of the pump

and pressure regulator and any accessories or motors.

b) Please contact the agent in your zone, the nearest authorised workshop

or UNIGREEN S.p.A. directly for any repairs the user feels they aren’t capable

of performing alone. (see point 10.4)

c) Due to the complexity of the equipment and the variety of technologies

used (mechanical, hydraulic, oil-pressure and electrotechnical) operators must

not dismantle or modify the equipment. All of the relevant operations must be

performed by specialised personnel, authorised by UNIGREEN S.p.A.

2.4.1 TAKING PRECAUTIONS AGAINST FIRE HAZARDS

Don’t use naked flames or heat sources near the machines.

The atomisers are made with many materials that derive from petroleum:

tanks, tubes, pipes and hoses, wheels and plastic parts; furthermore the

presence of oils of various nature and residues of chemical products make

them potentially flammable.

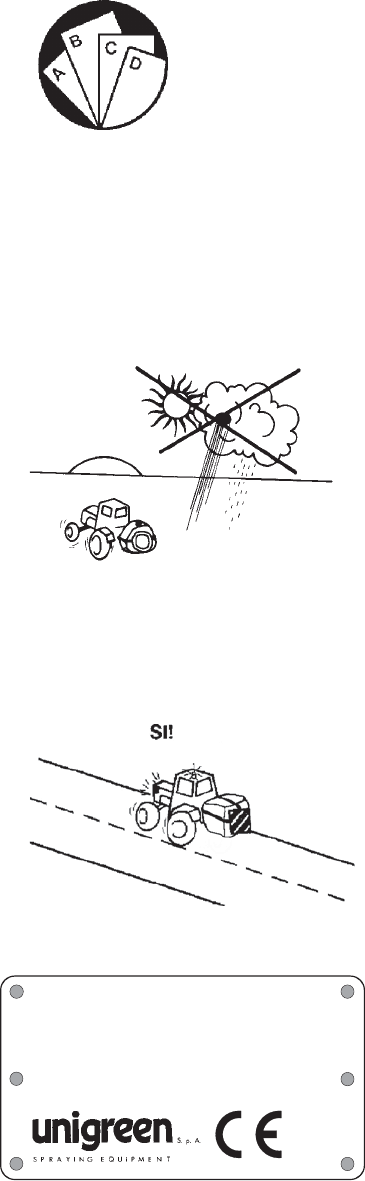

2.5 WEATHER CONDITIONS

We recommend spraying in the early hours of the morning or late in the

afternoon, avoiding the hottest time of day.

Never do any spraying if it’s raining or rain is forecast.

Don’t spray in strong wind or in any case, in winds above 3/5 m/second.

If you have to spray in windy conditions, use relatively low pressures to obtain

quite large drops that are less sensitive to drifting (being heavier the wind has

less effect). There are also special anti-drift nozzles available from UNIGREEN

S.p.A.; for information, please contact our offices.

2.6 MACHINES DESIGNED TO BE USED ONLY WITH CLEAN WATER

There are versions of the machines designed only to be used with a hose reel

for washing with cold clean water.

These machines cannot be used with chemical products as they don’t have some

of the devices or accessories that are needed to use these products safely.

These machines are identified by the word “washing” on the CE plate.

2.7 DRIVING ON THE ROAD

The towed atomisers are not specifically designed for road use. Nevertheless,

many models are also available in the version homologated for road traffic with

the tank empty.

You should check with your local reseller on the correct couplings to use and

use tractors that meet the regulations in force.

3 CHARACTERISTICS AND SPECIFICATIONS

This handbook is valid for mounted atomisers with axial fans for phytosanitary

treatment in orchards and vineyards, in any case for arboreal cultivation in

rows of varying nature and type.

It is also valid for cannon atomisers for the phytosanitary treatment of tall

plants and forest trees such as poplars or similar.

The axial atomisers produce a mixed spray, breaking the drops with the

pressure and the speed of the air produced by the fan.

These atomisers produced by UNIGREEN SPA are identified by the CE plate

(FIG. 2) bearing one of the marks indicated in the tables of the allowed fittings

(see the following paragraph).

3.1 TABLES OF FITTINGS ALLOWED

Tables N° 14A-15A-16A let you identify the version of your machine indicating

the basic equipment and all the possible fittings available (optional).

You can also find the other fittings allowed or other versions to meet your

requirements in the future.

THE EQUIPMENT DEFINED IN THE TABLES OF THIS HANDBOOK (TAB:

14A-15A-16A, pages 37, 38, 39) SHOULD BE CONSIDERED BINDING FOR

THE VALIDITY OF THE DECLARATION OF CONFORMITY.

Other fittings or setups of basic components and/or optionals should be

considered unsafe and therefore are not covered by the guarantee and aren’t

UNIGREEN’s responsibility.

The same goes for fittings realised with components or accessories that aren’t

original UNIGREEN parts.

UNIGREEN accessories can easily be identified by the label with the yellow

background “ORIGINAL UNIGREEN ACCESSORY”

TYPE : .......................................................................

code: ........................................ N˚ ...........................

massa a vuoto: ..........................Kg. max press. : ........... bar

net mass

massa totale ammessa: .............................. Kg.

total mass

via Rinaldi, 105 - Reggio Emilia ITALIA

ANNO

YEAR

20 .......

made in

Italy

FIG. 2