18 unigreen

5.5 CLUTCH

Big aluminium and nylon blowers have a centrifugal type clutch that makes it

possible to engage the fan rotor gradually.

This prevents jerky starts, due to the inertia of the fan rotor, which can have a

negative effect on the transmission.

For the centrifugal clutch to work properly the speed of the power-takeoff

mustn’t be less than 450 rpm, especially if you are using the first gear of the

multiplier.

Generally clutches with shoes/plates made of sintered material with a high

coefficient of friction are fitted, on some low power models rubber clutches may

be fitted.

5.6 OPTIONAL DEFLECTORS AND ACCESSORIES

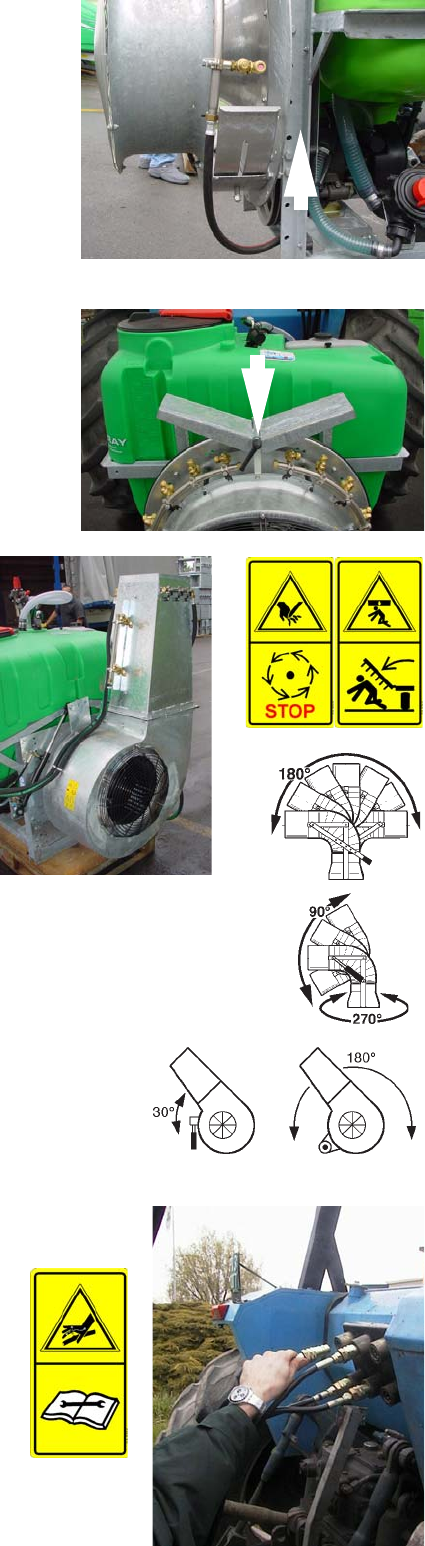

The atomisers are fitted with deflectors underneath for the optimal regulation of

the airflow towards the zone to be treated. To adjust these, simply pull or push

the deflector, positioning it in the desired way (FIG.23).

Top deflectors can also be supplied on request to improve the regulation of the

airflow towards the lateral zones without dispersing the product upwards. To ad-

just these, simply loosen the black lever (shown in figure 24), position the de-

flectors and lock the lever again.

5.7 CANNON BLOWER GROUP

The cannon blower group is equipped with a multiplier similar to the normal axial

blower groups and all of its operating characteristics are the same.

The main difference with respect to the axial blower groups is that the

centrifugal fan rotor is made of galvanised steel, the fan rotors in this type are

fixed and can’t be adjusted, for the clutch see the previous paragraph. This fan

rotor can usually produce a delivery which is much higher with a very high

speed airflow (Fig. 25).

The cannon fan is mounted on a thrust block that can be adjusted by hand by

unscrewing the relevant locking screw. This adjustment must be done with the

fan rotor stopped because the high speed of the air make the movement of the

fan dangerous.

5.7.1 MANUALLY INCLINABILE HEAD

The cannon blower group can be equipped with a pivoting head (max inclination

180°) adjustable by hand.

5.7.2 HYDRAULIC DRIVEN HEADS

On request hydraulic pivoting (inclination 90° roughly) and rotating (max rotation

270°) heads are available.

5.7.3 HYDRAULIC DRIVES

The cannon fans can be equipped with hydraulic drives: with the cylinder fitted

directly (30° inclination roughly) or a motor with a pinion and chain (180°

inclination roughly).

5.7.4 OIL FEED FROM TRACTOR

(for hydraulic systems)

Connect the delivery and discharge quick-fit coupling to the respective

connections, respecting the direction of flow.

The distributor inlet pipe is connected to the aluminium flow separator valve

next to the distributor.

The flow separator must be adjusted correctly so it sends less than 4-5 L/1° to

the distributor.

To prevent the cylinders moving at a dangerous speed, adjust the relevant

chokes near the cylinders. If the registration ringnuts aren’t visible then fixed

chokes are fitted. The chokes are fitted on the discharge line of the movement

to slow.

Any impurities in the oil could block the chokes and as a consequence block

the cylinder; remove the dirt if necessary. The maximum pressure valves of the

distributors are regulated to a pressure of around 150 bar.

FIG. 23

FIG. 24

FIG. 25