Carefully read this Section on mower

and engine maintenance and service.

Performing the required maintenance

according to schedule will ensure the

proper performance and long life of your

machine.

NOTE: All references to left, right, front

and rear of the machine are determined by

standing behind the handlebars and facing

the direction of forward travel.

IMPORTANT: REFER TO

MAINTENANCE CHART IN THIS

SECTION FOR A LISTING OF REGU-

LARLY SCHEDULED MAINTENANCE

PROCEDURES.

ENGINE SERVICE

Routine engine service is described

below. For more complete engine ser-

vice information, refer to the engine

manual provided with your machine.

For complete engine service, contact an

authorized engine dealer.

ENGINE OIL

OIL LEVEL: With mower on level

ground, the engine oil level must be be-

tween the "ADD" and "FULL" marks on

the dipstick at all times. Check before

each use and every 5 operating hours.

OIL CHANGE: On a new engine, change

oil after first 2 hours of use, then change

oil regularly as specified on the

Maintenance Chart. Refer to Engine

Owner's Manual for oil capacity.

OIL TYPE: Use clean, high quality deter-

gent oil having an A.P.I. service classifi-

cation of SE, SF or SG. Use no special

additives with oil. Refer to the Engine

Owner’s Manual for recommended SAE

viscosity grades that match the starting

temperature anticipated before the next

oil change.

Checking Oil Level:

1. Park machine on level ground.

2. Stop engine, wait for parts to stop

moving, and disconnect spark plug

wire.

3. Clean area around dipstick (Z, Figure

5-1) to prevent dirt from entering oil fill

hole.

4. Remove dipstick. Oil level must be

between “ADD” and “FULL” marks. Do

not exceed “FULL” mark on dipstick.

5. To add oil, pour slowly into dipstick

opening. While adding, check oil level

frequently by securely replacing dipstick

and removing to read oil level. Wipe dip-

stick clean each time oil level is

checked.

6. After filling to “FULL” mark, securely

replace dipstick.

Changing Oil:

Change oil while engine is still warm

from recent operation. Warm oil flows

more freely and carries away more im-

purities.

1. Stop engine, wait for parts to stop

moving, and disconnect spark plug

wire.

2. Remove dipstick (Z, Figure 5-1).

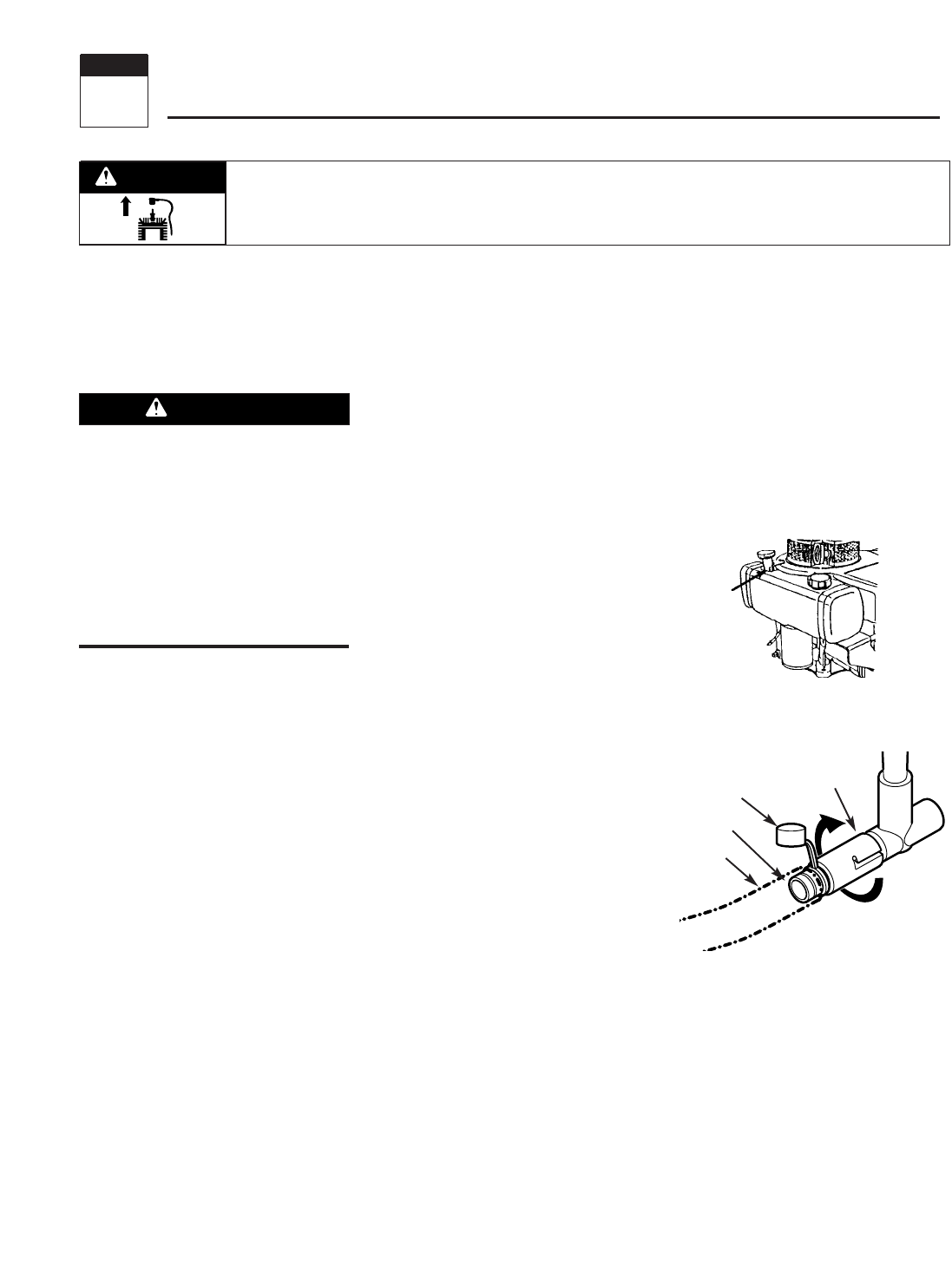

3. Remove protective cap (A, Figure 5-

2) to expose oil drain port (B).

4. Push oil drain hose (D) (included in

hardware bag with unit) onto oil drain

port. Route other end of hose to an ap-

propriate oil collection receptacle.

5. Twist oil drain fixture (C) to the open

position. Pull out. Drain oil completely.

6. Push in and twist oil drain fixture to

the closed position. Remove drain

hose. Replace protective cap (A).

7. Refill engine with fresh oil and se-

curely replace dipstick.

NOTE: Please dispose of all waste mate-

rials in an ecologically responsible man-

ner. Use proper waste material storage

containers.

Before inspecting, cleaning or servicing

the machine, shut off engine, make

sure that all moving parts have come to

a complete stop, disconnect spark plug

wire and move wire away from spark

plug. Remove ignition key on electric

start models.

Failure to follow these instructions can

result in personal injury or property

damage.

WARNING

Figure 5-1: Briggs and Stratton engine oil

fill.

Z

Figure 5-2: Oil drain.

C

A

B

D

Maintenance

5

Section

Before inspecting, cleaning or servicing the machine, shut off engine, wait for moving parts to stop, disconnect spark

plug wire and move wire away from spark plug. Remove ignition key (electric start models).

Failure to follow these instructions can result in serious personal injury or property damage.

WARNING

16