22

Section 5: Maintenance

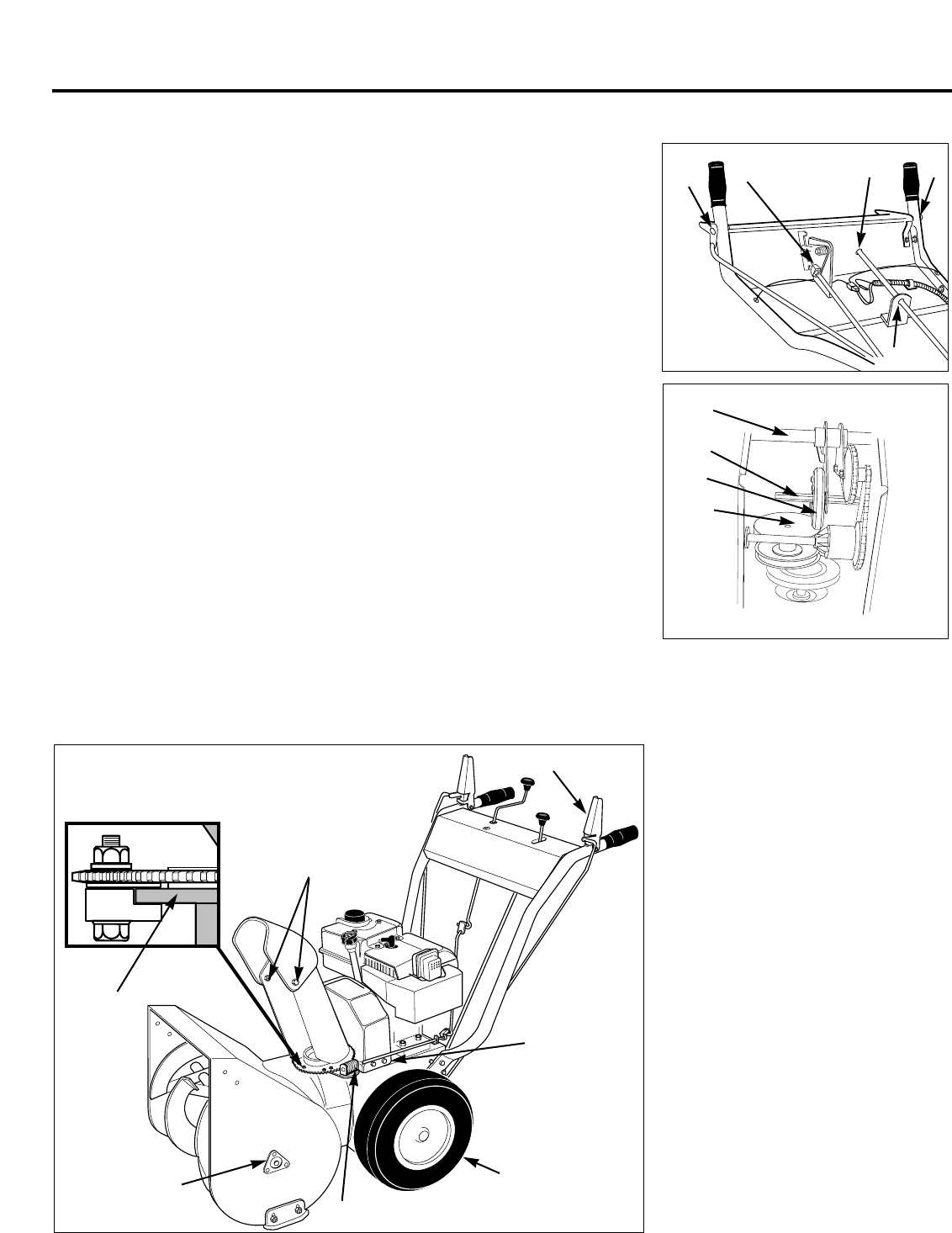

Lubrication

At the beginning and end of each season

or after every 25 hours of operation,

lubricate the unit as recommended below:

1. Lightly oil both the deflector chute cap

pivot points (D, Fig. 5-3).

2. Lightly oil the discharge chute control

rod pivot points where the control rod

enters the control panel bearing

(E, Fig. 5-4), the support tab

(F, Fig. 5-4), and the support on the

left rear of unit housing (G, Fig. 5-6).

3. Remove the left wheel (H, Fig. 5-3).

Clean the wheel shaft and apply multi-

purpose grease to the wheel shaft.

Reinstall the left rear wheel.

4. Apply oil to the bearings on sides of the

auger shaft (J, Fig. 5-3).

5. Clean dirt and old grease from the

flange at the bottom of the discharge

chute (K, Fig. 5-3). Apply multi-purpose

grease to the worm gear (C), toothed

portion of flange and the flange.

6. Lightly lubricate the handlebar control

levers at pivot points (M, Fig. 5-4) with

oil or a non-silicone spray. Do not get

oil or lubricating spray on levers.

7. Lightly oil the pivot points on the gear

shift control lever (N, Fig. 5-4).

8. Remove the two shear bolts (C, Fig. 5-

7) from the auger shaft, then lubricate

the four auger grease fittings (O, Fig.

5-7) using a grease gun. Rotate auger

three or four times. Reinstall shear

bolts, torque to 11 ft-lbs (15Nm).

9. Check the auger gear case oil level :

a. Place the unit on a smooth, level

surface. Unscrew the plug

(P, Fig. 5-7) from the front of

gear case.

b. Inspect plug hole. Oil should just

begin to seep out of the hole. Add

SAE 90 gear oil if necessary until

oil just begins to flow out of hole.

Let the excess oil drain out of the

gear case.

c. Reinstall the plug (P).

10. Remove bolts (Q, Fig. 5-6) securing

bottom cover to unit. Remove bottom

cover. Put gear shift lever in highest

speed setting and apply a coating of

multi-purpose grease to the shafts (R

and S, Fig. 5-5). Prevent grease from

contacting rubber drive wheel (T) or

drive disk (U). If grease should contact

these parts, wipe clean to avoid

slippage and assure proper operation.

Move shift lever between high speed

and reverse settings to spread grease

along shafts. Replace bottom cover.

Wheel Drive Disc Adjustment

Due to wear, the wheel drive control disc

may begin to slip when wheel drive

lever is engaged. To adjust wheel drive

disc:

1. Pull the wheel drive control arm

(V, Fig. 5-6) down completely.

2. Measure and note the distance

between the coiled ends of the spring

(W, Fig, 5-6).

3. Squeeze wheel drive control lever (X,

Fig. 5-3) against handlebar. Measure

Fig. 5-3

J

K

Fig. 5-4

F

D

X

M

N

E

M

AB

H

C

Fig. 5-5

R

S

T

U