13

Section 2: Assembly

K. Wiring Harness Installation

1. Remove the plastic cable tie that

secures the wiring harness to the right

handlebar.

2. Route the wiring harness to the inside

of the right handlebar and over to the

right side of the engine.

3. Attach the ring terminal (AK, Fig. 2-10)

on the two black wires to the screw on

the engine shroud as shown. The

lockwasher should be next to the

screw head and the ring terminal in

between the lockwasher and the

engine shroud.

4. Connect the spade terminal (AL, Fig.

2-10) on the black wire to the yellow

wire receptacle inside the connector

receptacle (AM). Note that there are

two yellow wires extending out of the

back of the receptacle (AM).

Do not install the spade terminal (AL)

into the receptacle for the yellow wire

that is attached with a small plastic

connector to the red wire.

5. Plug the wiring harness connector

(AN) into the engine connecting plug

(AO). Note that it can only be plugged

in one way.

6. Using two of the plastic cable ties

provided, loosely (to avoid stretching

wires) attach the upper section of the

wiring harness to the right handlebar.

Use the third cable tie to loosely tie the

black, blue and red wires together at

the side of the engine. Be sure that the

wires are positioned safely away from

the wheel.

M. Check Auger Gear Case Oil

Level

The auger gear case was filled at the

factory with the correct amount of SAE 90

gear oil. This level should be checked

before using the unit. Refer to

“Lubrication” in the Maintenance section

of this manual for complete information.

N. Check Tire Pressure

Check the air pressure in both tires using

an automotive-type tire pressure gauge.

Inflate tires evenly to 8-12 psi (55-82 kPa).

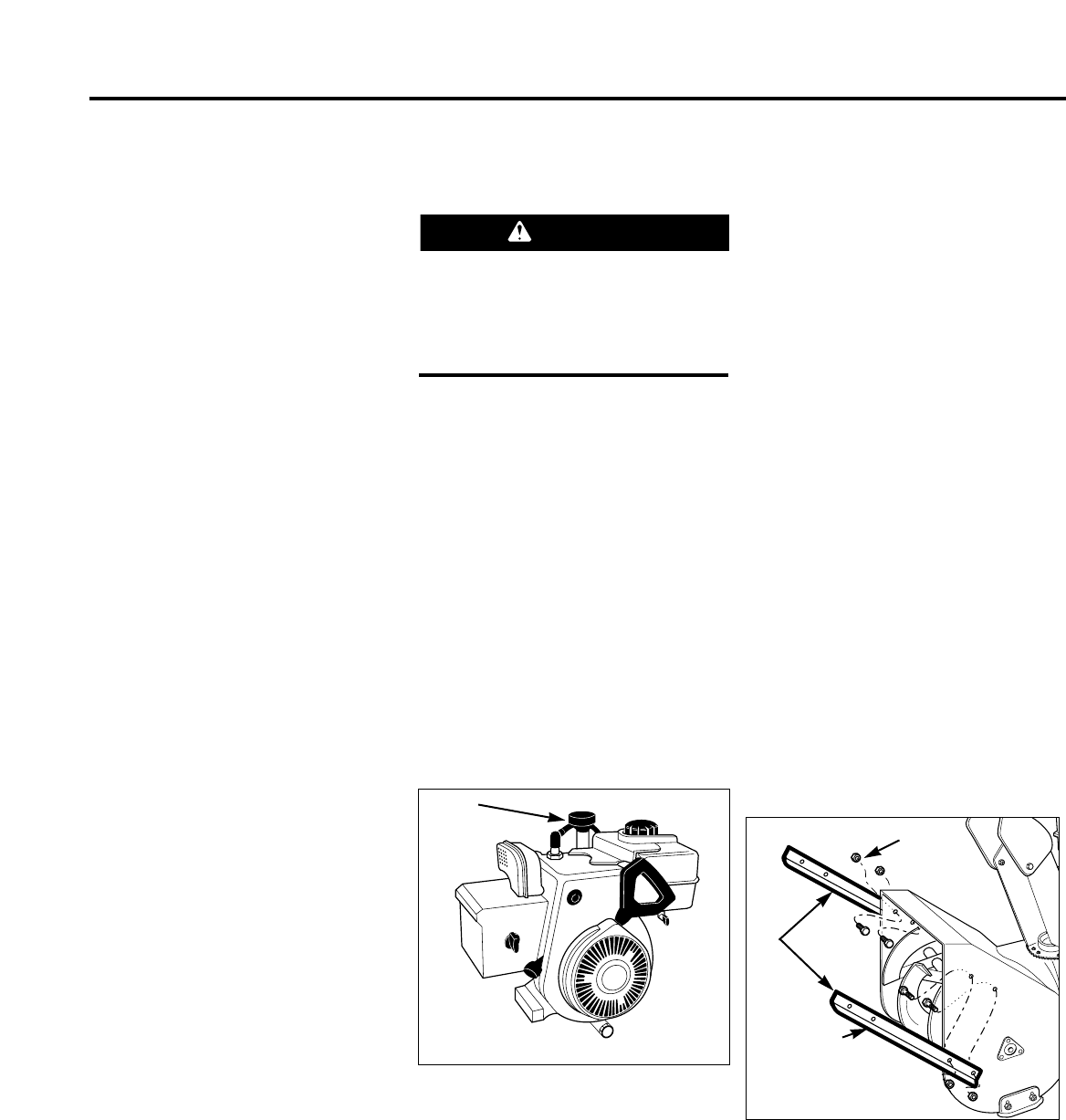

O. Install Drift Slicers (optional

attachment)

The optional drift slicers (AR, Fig. 2-12)

are designed for use in deep snow

conditions. To install the drift slicers:

1. Position the drift slicers (AR, Fig. 2-12)

to the outside of the auger housing.

2. Attach the drift slicers with the four

5/16–18 x 3/4 screws and locknuts

(AS) provided with the drift slicers.

L. Add Engine Oil to Crankcase

1. Be sure that the engine is level before

checking or adding oil.

2. To add engine oil, unscrew dipstick

(AP, Fig. 2-11). Fill oil at the dipstick

opening with fresh oil. See the engine

owner manual for correct oil specifica-

tions and quantity required. Do not

use SAE 10W40.

3. Oil level on dipstick should always be

above “ADD” and below “FULL”. Wait

a few minutes after filling crankcase,

allowing oil to settle. Insert dipstick

and tighten securely. Recheck level

and adjust as necessary.

WARNING

DO NOT START ENGINE UNTIL ENGINE

CRANKCASE HAS BEEN FILLED WITH

OIL. FAILURE TO FOLLOW THIS

INSTRUCTION WILL RESULT IN SERIOUS

ENGINE DAMAGE.

Fig. 2-11

AP

AR

AS

AS

Fig. 2-12