Groundsmaster 4500--D/4700--DPage 6 -- 30Axles, Planetaries and Brakes

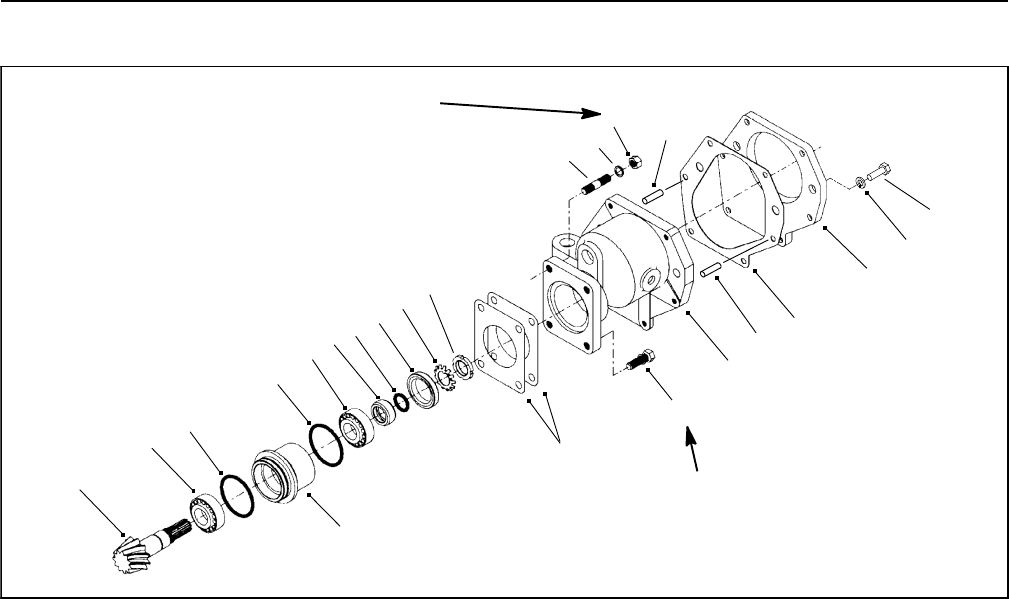

Input Shaft/Pinion Gear

Figure 35

1

1. Nut (2 used)

2. Lock washer (2 used)

3. Stud (2 used)

4. Lock nut

5. Stake washer

6. Oil seal

7. O-ring

8. Seal collar

9. Bearing

10. O-ring

11. Input shaft/pinion gear

12. Bearing case

13. Shim

14. Screw (2 used)

15. Gear case

16. Gasket

17. Cover plate

18. Dowel pin

19. Lock washer (6 used)

20. Cap screw ( 6 used)

2

3

4

5

6

7

8

9

10

9

11

12

13

14

15

16

17

10

18

18

35 to 41 ft--lb

(47 to 56 N--m)

35 to 41 ft--lb

(47to56N--m)

19

20

The following procedures assume the rear axle assem-

bly has been removed from the machine.

Removal (Fig. 35)

1. Remove the cover plate, gasket and gear case as-

sembly from the axle assembly. Remove the gasket and

any remaining gasket material.

2. Remove the retaining rings and the driven gear from

the input shaft/pinion gear.

3. Remove input shaft/pinion gear assembly from the

gear case. Remove the shims and bearing case O-

rings.

4. Release the stake washer and remove the lock nut.

Remove and discard the stake washer.

5. Drive the input shaft/pinion gear out from the outer

bearing cone and bearing case. Remove and discard

the oil seal and O-ring.

6. Inspect all gears, shafts, bearings, spacers and

cases for damage and wear. Replace components as

necessary.

NOTE: Replacement input shaft/pinion gear (item 11)

is only available in matched set with differential ring

gear.

Installation (Fig. 35)

NOTE: When installing bearing cones onto the input

shaft/pinion gear, press only on the inner race of the

bearing cone.

1. If the inner bearing cone was removed, press a new

bearing cone all theway onto the input shaft/pinion gear.

2. Place the shaft and bearing assembly in the bearing

case and install t h e outer b earing cone.

NOTE: The bearings must be completely seated.

There should be no input shaft/pinion gear end play.

3. Coat a new oil seal with grease and install as shown

(Fig. 36). The seal should be installed with the garter

spring towards the hydraulic motor location.

4. Coat new O-ring with grease. Install O-ring in the oil

seal collar and install the collar.