Groundsmaster 4500--D/4700--D Page 5 -- 41 Electrical System

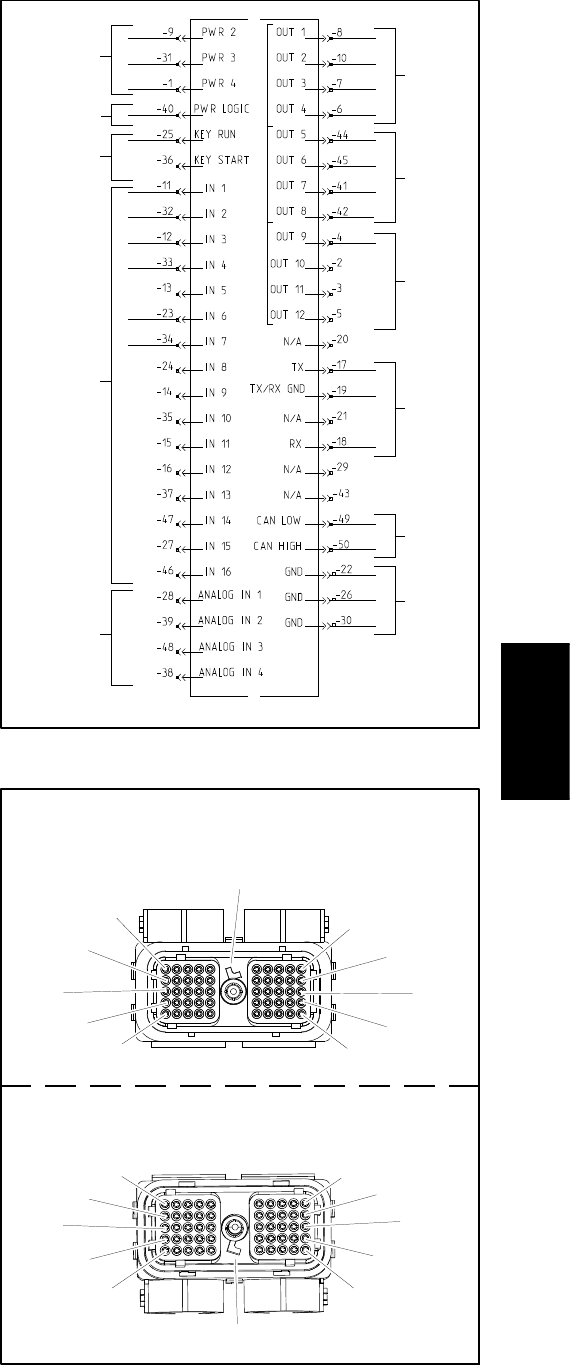

The connection terminal functions for the TEC c ontrol-

lers are shown in Figures 48 (TEC--5002) and 49

(TEC--5001). Note that electrical power for controller

outputs is provided through three (3) connector termin-

als (PWR 2, PWR 3 and PWR 4) each protected with a

7.5 amp fuse. A fifty (50) pin wire harness connector at-

taches to each controller. The wire harness connector

pins are identified in the diagram in Figures 48 and 49.

The layout of the wire harness connectors that plug into

the TEC controllers is shown in Fig. 50.

IMPORTANT: When testing for wire harness con-

tinuity at the connector for the TEC controller, take

care to not damage the connector pins with multi-

meter test leads. If connector pins are enlarged or

damaged during testing, connector repair will be

necessary for proper machine operation.

The machine electrical schematic and wire harness

drawings in Chapter 9 -- Foldout Drawings can be used

to identify possiblecircuit problems between the control-

lers and the input/output devices (e.g. switches and

solenoid coils).

Because of the solid state circuitry built into the TEC

controllers, there is no method to test a controller direct-

ly. A controller may be damaged if an attempt is made

to test it with an electrical test device (e.g. digital multi-

meterortestlight).

NOTE: The two (2) TEC controllers used on the

Groundsmaster 4700--D are matched for correct ma-

chine operation. If either of these components are re-

placed for any reason, system software needs to be

reprogrammed by your Toro Distributor.

IMPORTANT: Before performing welding on thema-

chine, disconnect both positive and negative bat-

tery cables from the battery, disconnect the wire

harness connector from the TEC controllers and

disconnect the terminal connector from the alterna-

tor. Also, disconnect and remove the engine ECU

from the machine before welding. These steps will

prevent damage to the machine electrical system

when welding.

Figure 49

12V POWER

(7.5AFUSES)

12V LOGIC

IGNITION

SWITCH

INPUTS

DIGITAL

INPUTS

(OPEN/

ANALOG

INPUTS

POWER

(2AMP FUSE)

COMM

PORT

CAN BUS

CLOSED)

OUTPUTS

(PWR 2)

GROUND

(VARIABLE)

OUTPUTS

(PWR 3)

OUTPUTS

(PWR 4)

TEC--5001

Figure 50

WIRE HARNESS CONNECTOR FOR

TEC--5002 CONTROLLER

1

11

21

31

41

30

20

10

40

50

NOTE TAB POSITION

1

11

21

31

41

30

20

10

40

50

NOTE TAB POSITION

WIRE HARNESS CONNECTOR FOR

TEC--5001 CONTROLLER

Electrical

System