MODEL 2230R, Process Hydrogen Analyzer

Page 20

5. MAINTENANCE

5.1 CLEANING

If the unit is exposed to process streams containing debris, condensates or other material that

may collect over the sensor tip then the unit should be removed from the stream periodically

and the tip cleaned by a gentle wiping with a clean lint-free cloth or paper.

5.2 CALIBRATION INTERVAL

TELEDYNE ANALYTICAL INSTRUMENTS recommends that the system calibration be carried out if

the unit fails Verification. Field Verification can occur as often as needed and is recommended

when the tolerated sensor drift may result in unacceptably high errors. Anticipated drift rates

and error calculations are explained in the Verification section of this manual. The user has two

choices in calibrating the unit:

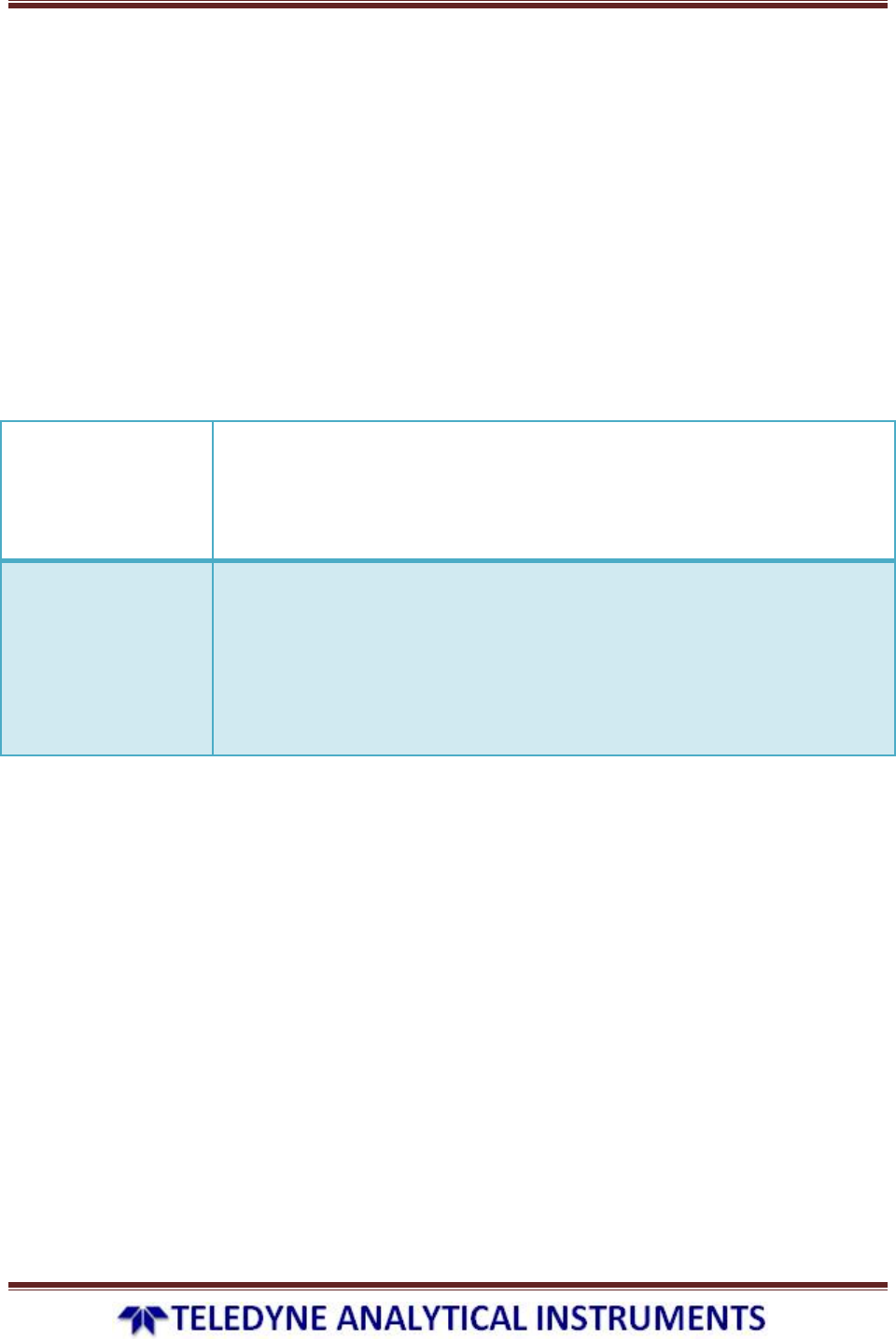

Factory

Calibration

Contact TELEDYNE ANALYTICAL INSTRUMENTS to make arrangements

for a comprehensive Factory Calibration using high accuracy gases by

TELEDYNE ANALYTICAL INSTRUMENTS’s factory trained technicians;

optional NIST traceable certificate available upon request. An annual

Factory Calibration is advisable to optimize performance.

Field

Calibration

Refer to Sections 4.4 and 4.5 for the operational procedure. Customer-

specific Field Calibration Kits for the Model 2230R analyzer is available

from TELEDYNE ANALYTICAL INSTRUMENTS. Field Calibration is a 3 stage

process:

1. Run Field Verification,

2. Run Field Calibration,

3. Repeat the Field Verification to confirm a successful Field Calibration.

In the event the Field Calibration procedure seems to not be effective, TELEDYNE ANALYTICAL

INSTRUMENTS recommends the unit be shipped back to the factory for a comprehensive

evaluation and Factory Calibration.

5.3 FIELD VERIFICATION & FIELD CALIBRATION GASES

Field Verification and Field Calibration require the availability of at least two certified known

gases at values specific to the user’s application. For optimization, the hydrogen concentrations

of the gases implemented in Field Verification and Field Calibration must be the same. Flow

rate recommended is 0.5 ± 0.2 slpm.

Verification / Calibration in an Inert (i.e. nitrogen) Background Gas:

For a unit calibrated in an inert gas (i.e. nitrogen) background, carry out Verification and

Calibration in an inert (i.e. nitrogen) gas background.

Gas Connection

Gases are applied to the unit through user’s piping.