BIL-JAX 3522A

28

TROUBLESHOOTING

Refer to Table 4-1 for basic troubleshooting operations. Additional information

can be found in the Bil-Jax Model 3522A Parts and Service Manual. Contact the

Bil-Jax Service Department with any questions or before attempting any

advanced troubleshooting operations.

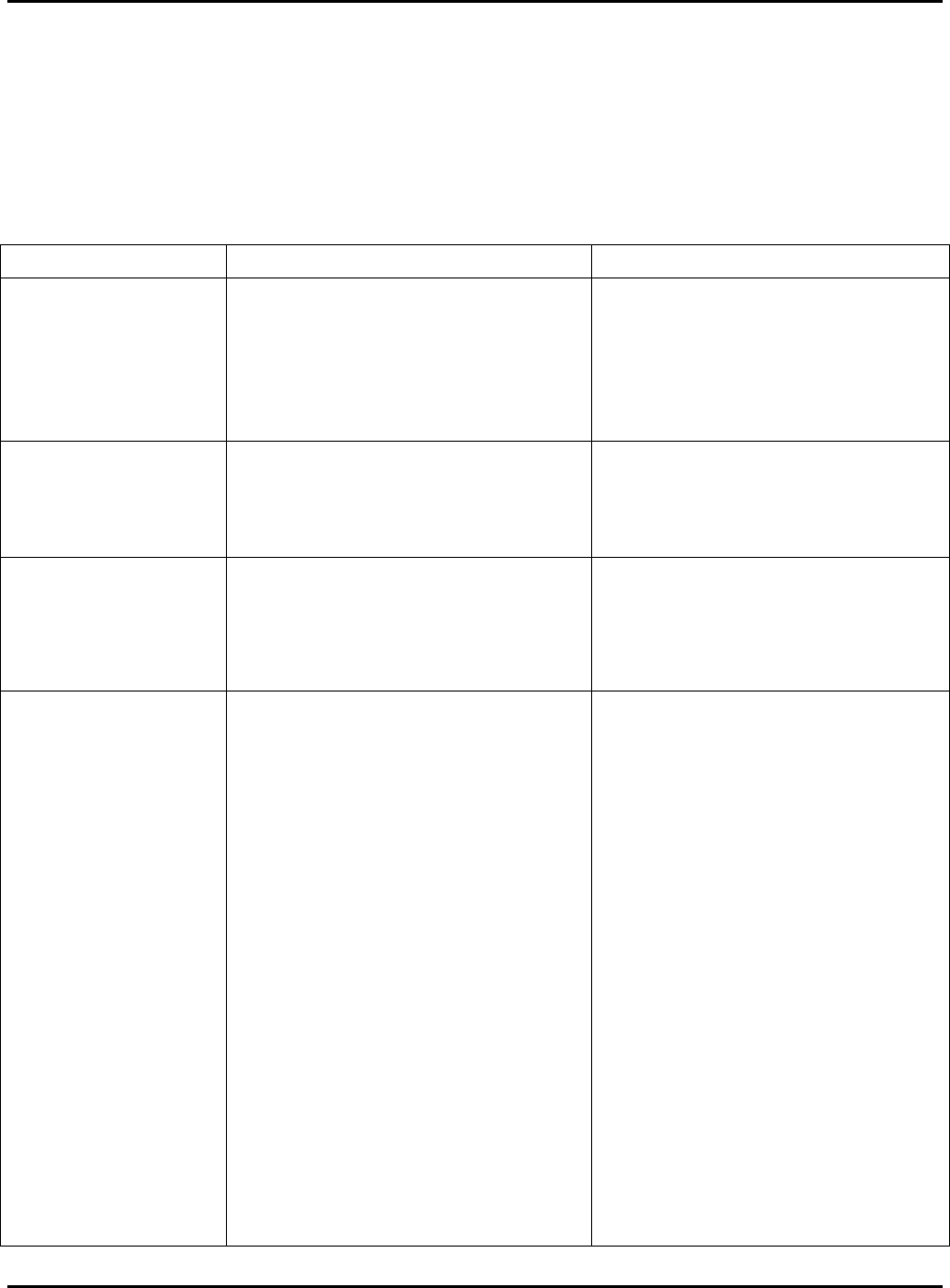

Table 4-1. Troubleshooting Steps

PROBLEM CAUSE SOLUTION

No lights on panel when

key switch is turned to the

on position.

a. Emergency STOP engaged.

b. Battery charge is low.

c. Battery ground or in-series cable is loose.

d. Battery main disconnect unplugged.

a. Disengage Emergency STOP buttons.

b. Recharge as needed.

c. Inspect and repair battery connections.

d. Plug in main disconnect.

Hydraulic function does not

work and display window

shows an error message

a. Fault detected by safety interlock

microprocessor.

b. Boom Lift electric or electronic failure

a. Refer to Table 4-2 for error code

definition and correction.

b. Refer to Table 4-2 for error code

definition and correction.

Outrigger indicator LED

lights do not function.

a. Key switch turned to the OFF or platform

controls position.

b. Emergency

STOP engaged.

c. Outriggers not deployed.

a. Turn key switch to ground controls

position.

b. Disengage emergency STOP buttons.

c. Deploy all outriggers.

One or more boom controls

do not function

OR

One or more boom controls

function improperly

OR

One or more boom controls

function intermittently.

a. Key switch is turned to the OFF or

incorrect control position.

b. Battery charge is low.

c. Emergency

STOP engaged.

d. Battery ground or in-series cable loose.

e. All outriggers not properly deployed.

f. Hydraulic pump inoperative.

g. Loose wiring connector.

h. Valve solenoid not operating properly.

i. Fault detected by system interlock.

j. Broken or loose wire.

a. Turn key switch to ground or platform

controls position.

b. Recharge battery.

c. Disengage Emergency STOP buttons.

d. Inspect and repair battery connections.

e. Deploy all outriggers and level boom lift.

f. Inspect pump; replace or repair as

needed.

g. Check wiring terminals in control box

and at valve manifold; replace or repair

as needed.

h. Clean valve solenoid and recheck

function(s); replace or repair as needed.

i. Check display for system status. Refer

to Table 4-2 for error code definitions

and correction.

j. Inspect wiring in control box and at

valve manifold and valve coil; repair or

replace as needed.