14

CHAIN TENSION ADJUSTMENT

Correct chain tension is very important throughout the life

of the chain. Check the chain tension often during use

(when the chain saw is stopped and the saw bar and chain

have cooled off). The chain should move easily around the

saw bar when pulled by hand. To adjust the chain tension:

1. Turn off the water and power supplies.

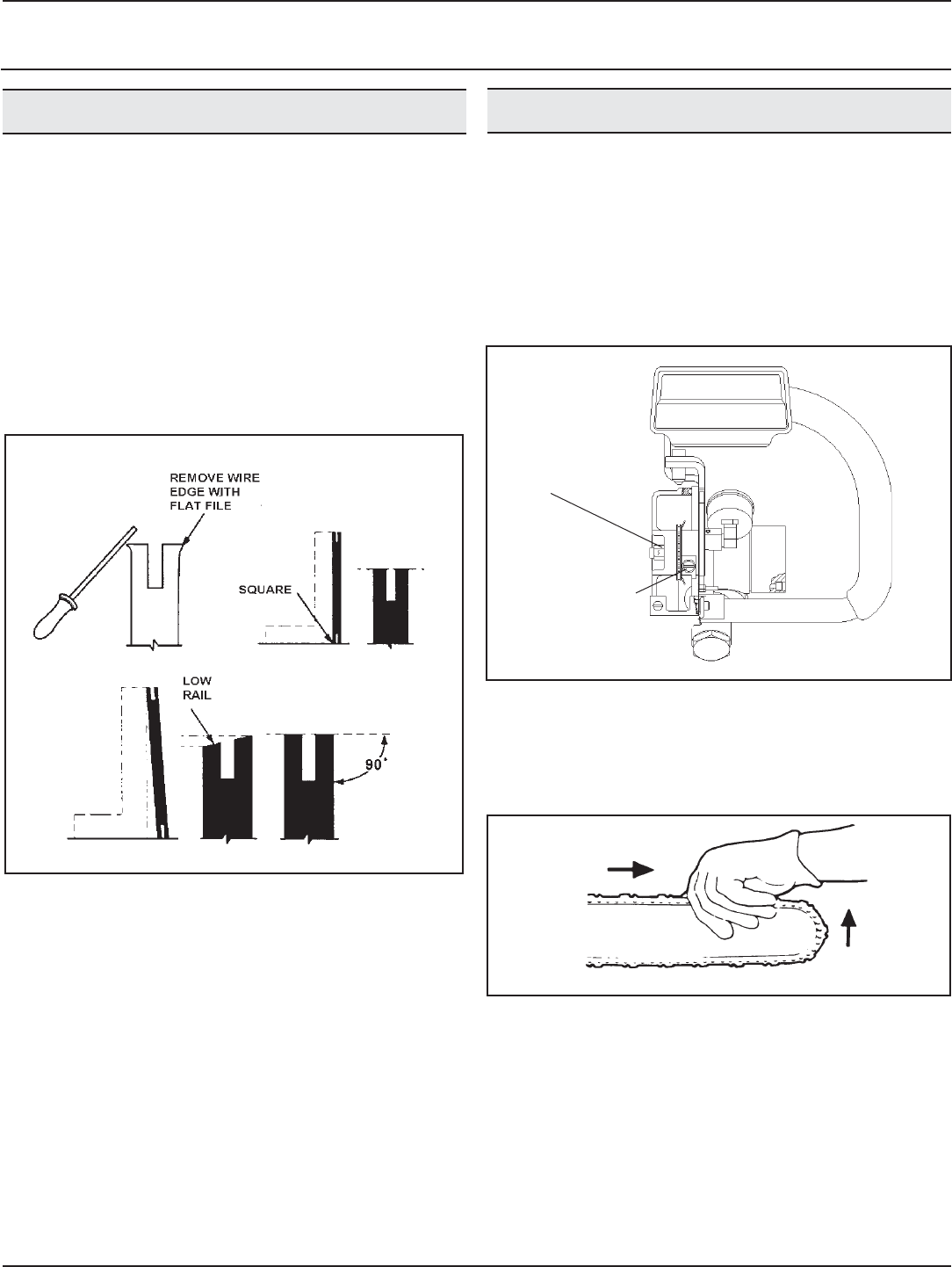

2. Loosen the two saw bar attachment nuts (Figure 8).

Figure 8. Attachment Screw Locations

3. Using the saw bar adjustment screw (Item 68, Parts Il-

lustration), tighten the chain until you are still able to rotate

it one full revolution by hand (Figure 9).

Figure 9. Pulling the Chain

4. Pull the chain around the saw bar to make sure it proper-

ly fi ts the sprocket and saw bar. The chain should be easily

pulled.

5. Fully tighten the two saw bar attachment nuts (Figure 8).

Note:

Adjust the chain tension each time the drive link tang

hangs fully exposed from the groove at the bottom of

the saw bar (Figure 10).

GENERAL MAINTENANCE TIPS

Several simple maintenance tasks which, if performed, can

keep a chain saw operating at a high level of effi ciency.

Routine maintenance also keeps replacement costs down

on the parts of the chain saw, which occasionally wear out.

If any chain saw disassembly is required, refer to the Ser-

vice Manual.

SAW BAR RAIL

A quick check can be made to determine if saw bar rail or

chain segment wear exists. Figure 7 shows a worn saw bar

rail.

Figure 7. Rail Wear

If the saw bar rails are worn, use a fl at fi le and dress each

one until it is fl at and square with the side of the saw bar

(Figure 7).

Also make sure the saw bar is perfectly straight. If bows

or bends are present in the saw bar, it must be replaced

before dressing any rail.

ROTATING THE SAW BAR

Maximum saw bar life can be achieved by occasionally

turning the bar over so the top and bottom bar surfaces

wear evenly. Refer to the saw bar disassembly procedures

in the Service Manual for further details.

MAINTENANCE & ADJUSTMENTS

Bar Attachment

Nuts (2)

Bar Adjusting Screw