Page 14

SERIES 28HE BOILER INSTALLATION AND OPERATION INSTRUCTIONS

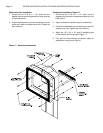

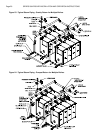

Figure 15 - Back Section Tapping Locations

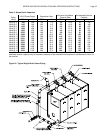

Table 5 - Water & Steam Tappings

Relief & Safety Valve Piping

Install the pressure relief or safety valve in the 3" NPT

opening in the top of the back section, Figure 14.

WARNING: The discharge of the pressure relief

or safety valve must be piped close to the floor

to prevent scalding in the event of a discharge,

see Figure 16. The discharge piping must be

sized the same as the pressure relief or safety

valve outlet. Never install any type of valve

between the boiler and the pressure relief or

safety valve! Failure to comply with this

warning can result in an explosion causing

extensive property damage, severe personal

injury or death!

GENERAL PIPING REQUIREMENTS

CAUTION: Never use automotive antifreeze in the

boiler or heating system. If antifreeze is necessary

it must be formulated specifically for hydronic

heating systems, such as ethylene or propylene

glycol. Failure to comply with this caution will void

the warranty!

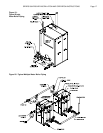

All heating system piping must be installed by a qualified

technician in accordance with the latest revision of the

ANSI/ASME Boiler and Pressure Vessel Code, Section

IV. Also ANSI/ASME CSD-1, Standard for Controls and

Safety Devices for Automatically Fired Boilers where

required. All applicable local codes and ordinances must

also be followed. A minimum clearance of 1" must be

maintained between heating system pipes and all

combustible construction.

CAUTION: Improper piping of this boiler can result

in poor performance and premature failure of the

boiler voiding the warranty! Improper piping can

also cause flooding and extensive property damage!

Ensure that the boiler is level from front to back and from

side to side. Use metal shims to level the boiler. NEVER

use wood, plastic or other combustible materials as

shims.

If a boiler is installed above any radiation elements it

must be fitted with a low water cutoff device.

NOTE: Install the observation port assembly before

making any return piping connections as access

may be blocked by piping.

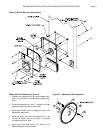

Figure 14 - Front Section Tapping Locations

Tapping Size Water Steam

1 1/8" Chamber Pressure Chamber Pressure

2 3/4" Probe LWCO

3 3/4" Temp./Pressure Gage

4 3/4" Operating Control - Top Water Glass

5

3/4"

Manuel Reset Manuel Reset High

High Limit Limit & Steam Gage

6 1" Air Removal Water Column - Top

7 6" Water Supply Skim Tapping

8 3/4"

Tankless Heater

Operating Control

9 1 1/2" Inspection Tapping - Top

10 1" Water Column - Bottom Water Column - Bottom

11 4" Boiler Drain Boiler Drain/Blowoff

12 4" Return Return

13 Relief Valve Safety Valve