Page 10

SERIES 28HE BOILER INSTALLATION AND OPERATION INSTRUCTIONS

9. Assemble the rest of the sections following steps 3

through 8 above.

10. Hydrostatically test the boiler by following the

instructions on page 8.

11. While the boiler is being filled confirm that all

of the draw rods are properly torqued and that

there are no leaks.

12. If any leaks are found tighten the draw rods on that

section until the leak stops.

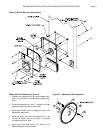

Heat Transfer Rod Installation, Figure 7

The high efficiency 28HE comes with design certified

heat transfer rod sets. Each tube of 15 heat transfer rods

will baffle one flue. In order to obtain the high efficiency

for which the boiler was designed, the heat transfer rods

must be properly installed, Figure 7.

Figure 7 -Heat Transfer Rod Installation

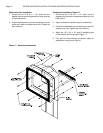

Cleanout Cover Installation

1. The cleanout covers come insulated from the

factory. Inspect the covers to ensure that the

insulation is not damaged or missing. If it is call the

Smith Customer Service Department.

2. Trim the 1/2" rope that’s sticking out around the

cleanout opening flush with the castings to insure

an air-tight seal, see Figure 5.

3. Install the cleanout cover bolts from the baffled side

of the cleanout cover and start the nuts, Figure 8.

4. Rotate the bolts so the cam heads fit between the

cleanout cover bosses on the castings.

5. Insert the cleanout cover and tighten the nuts to

15 ft lbs,

21 Nm

.

6. Apply a bead of high temperature silicone caulk

around the perimeter of the cleanout cover to

ensure an air tight seal.

Figure 8 - Cleanout Cover Assembly

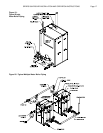

Burner Mounting Plate Installation, Figure 9

1. Apply two coats of the spray adhesive supplied with

the boiler to the rope groove on the plate. Allow time

for the first coat to dry then apply the second coat.

When the second coat is tacky lay the 3/8" rope into

the rope groove and press in place.

2. Screw the four 7/16-14 x 2 1/2" studs into the

tapped holes in the boiler front section, Figure 9.

3. Install the burner mounting plate insulation block in

the burner opening in the front section of the boiler.

The small observation port cutout must be on the

top, left side.

4. Position the front jacket panel frame over the four

studs, Figure 9.

5. Align the four holes in the burner mounting plate

with the 7/16" studs and force the burner insulation

block inward until the studs extend far enough

through the burner mounting plate holes so the nuts

can be started. Lightly tighten the nuts.

6. Carefully insert the 1/4-20 x 5" machine screws

through the holes in the burner mounting plate and

insulation block, Figure 9. Reach through the inside

of the burner opening and install the stainless steel

fender washers and nuts and snug the nuts down.

CAUTION: The burner insulation block must be

supported from the inside to prevent it from tearing.

Don't force the bolts through the block or over

tighten the nuts or the block with be damaged!