12

TF22221

50-Hour Maintenance

CAUTION!

Make sure you do not pierce the fuel line

with the end of the hooked wire. The line

is delicate and can be damaged easily.

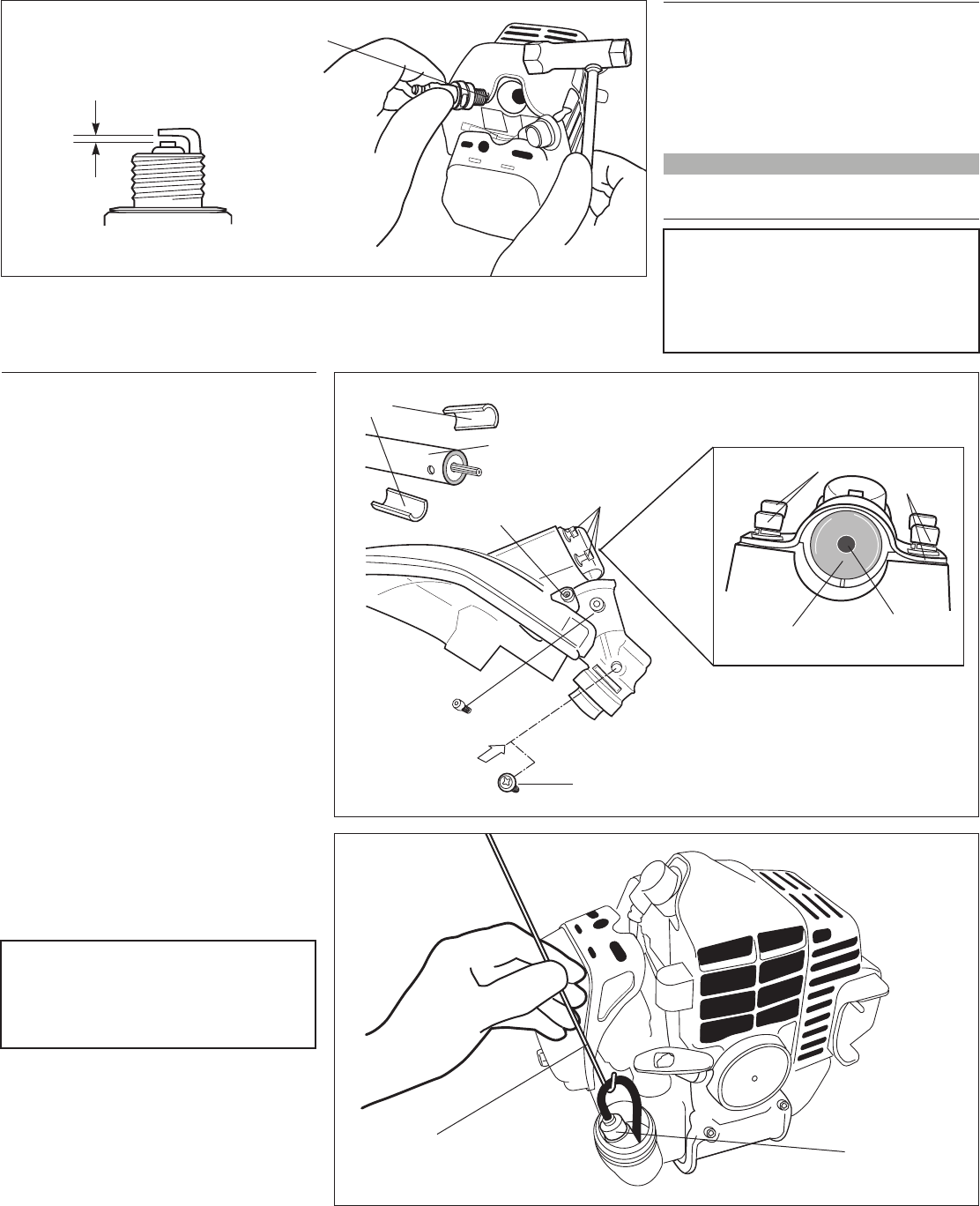

Every 10 to 15 hours of operation:

Remove and clean the spark plug. Adjust

the spark plug electrode gap to 0.024-

0.028 inch (0.6-0.7 mm). If the spark plug

must be replaced, use only an BPMR6A

or equivalent resistor type spark plug of

the correct heat range. See Figure 22.

■

CAUTION!

Before removing the spark plug, clean

the area around the plug to prevent

dirt and debris from getting into the

engine’s internal parts.

10/15-Hour Maintenance

NOTE:

The BPMR6A also meets the requirements

for electro-magnetic compliance (EMC).

Every 50 hours of operation (more

frequently in dusty or dirty conditions):

Gearcase Lubrication (T222 Only)

To perform this operation, first remove

the gearcase and debris shield from the

outer tube as follows. See Figure 23.

Remove the index bolt from the

gearcase.

Loosen the gearcase clamp screw.

Loosen the four socket head cap screws

that secure the cutting attachment

shield.

Slide the gearcase and cutting

attachment shield off the tube. (Do not

lose the two shims).

Remove the filler plug and press new

grease into the gearcase until old grease

is purged from the gearcase, which can

be seen in the outer tube cavity.

Clean up the excess grease and rein-

stall the cutting attachment shield, two

shims and the gearcase.

Remove and replace the lter

element.

1.

■

■

■

■

2.

3.

Use a hooked wire to extract the fuel

filter from inside the fuel tank. See

Figure 24.

Before reinstalling the new filter element,

inspect the condition of all the fuel system

components (fuel pick-up line, fuel return line,

tank vent line, tank vent, fuel cap and fuel

tank). If damage, splitting or deterioration is

noted, the unit should be removed from service

until it can be inspected or repaired by a

Shindaiwa-trained service technician.

1.

Shims

Clean the spark

plug and check

the gap at the

electrode.

0.024–0.028 inch

(0.6–0.7 mm)

Figure 22

Figure 24

Filter Element

Hooked

Wire

4 Socket Head Screws

Clamp Screw

Outer Tube

Figure 23

Index Bolt

Outer Tube

Cavity

4 Socket Head

Screws

Grease Plug

New Grease

Old Grease