OPERATION

OPERATION

Operation Section 4-13

© 2004 Alamo Group Inc.

FM84A 09/03

When fitting the mower to the tractor, the telescoping driveline must be inspected to ensure that at its most

compressed position, the profiles do not “bottom out”, and when at its farthest extended position, there is

sufficient engagement between the profiles to operate safely. At its shortest length, there must be at least

a 1” clearance between each profile end and opposite profile universal joint. At its farthest operating extension,

a minimum profile engagement of 12” must be maintained.

7.1 Driveline Length Modification

Before operating the Mower, check to make sure the driveline will not bottom out or

become disengaged. Bottoming out occurs when the inner shaft penetrates the outer

housing until the assembly becomes solid-it can shorten no more. Bottoming out can

cause serious damage to the Tractor PTO by pushing the PTO into the Tractor and through

the support bearings or downward onto the PTO shaft, breaking it off.

WARNING!

7. DRIVELINE ATTACHMENT

The driveline yoke and tractor PTO shaft must be dirt

free and greased for attachment.

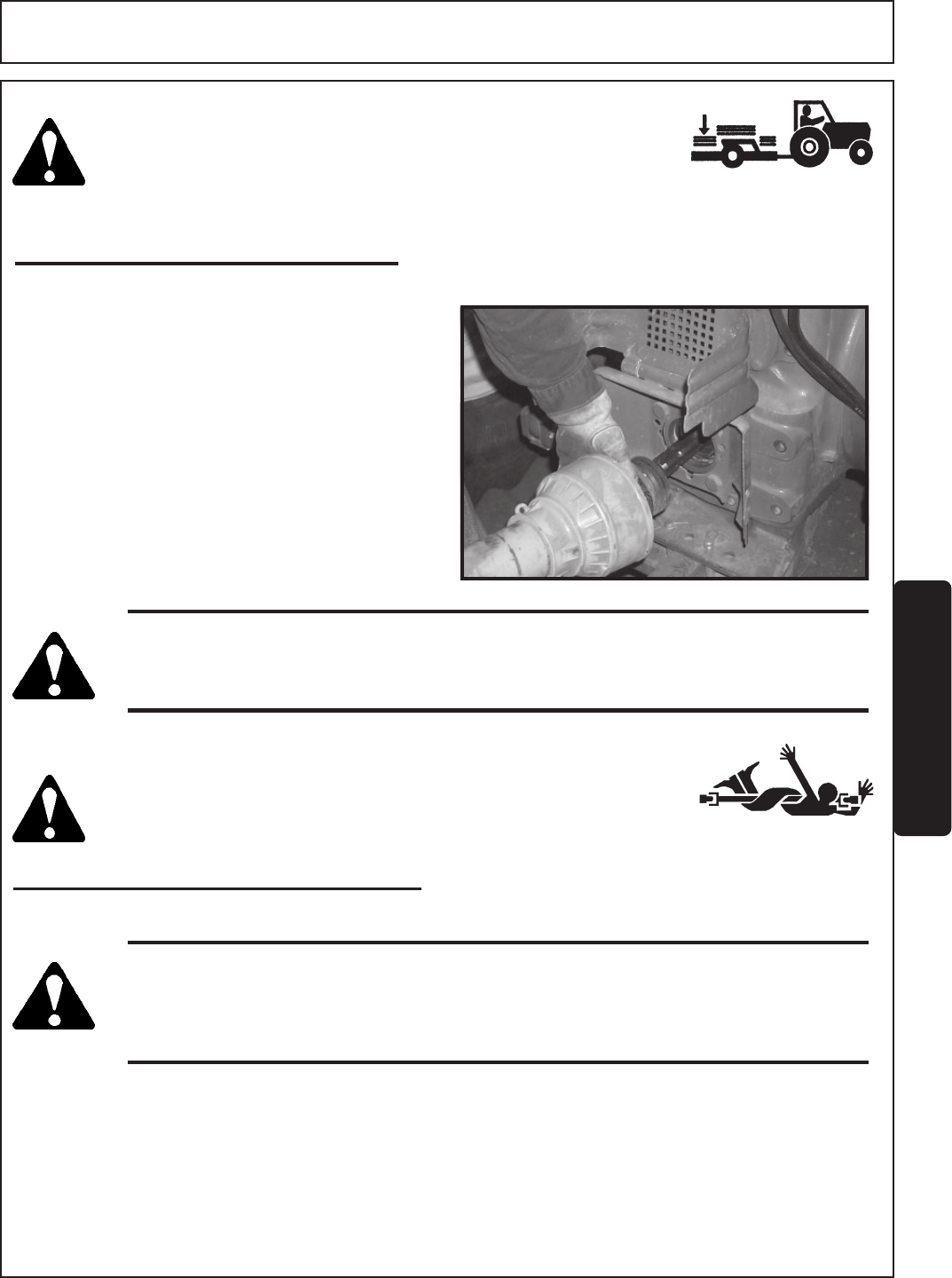

To connect the mower driveline to the tractor PTO output

shaft, pull the driveline yoke collar back and align the

grooves and splines of the yoke with those of the PTO

shaft. Push the driveline yoke onto the PTO shaft,

release the locking collar, and position the yoke until

the locking collar balls are seated onto the PTO shaft.

Push and pull the driveline back and forth several times

to ensure a secure attachment.

WARNING!

When attaching the PTO yoke to the Tractor PTO shaft, it is important that the spring

activated locking collar slides freely and the locking balls are seated securely in the

groove of the PTO shaft. A driveline not attached correctly to the Tractor PTO shaft could

slip off and result in personal injury and damage to the cutter.

DANGER!

Make sure the PTO shield is installed when using PTO-driven equipment.

Always replace the PTO shield if it is damaged or missing. (S3PT-8)

WARNING!

Relieve hydraulic pressure prior to doing any maintenance or repair work

on the Implement. Place the Implement on the ground or securely

blocked up, disengage the PTO, and turn off the tractor engine. Push

and pull the Remote Cylinder lever in and out several times prior to

starting any maintenance or repair work. (S3PT-9)