Pin

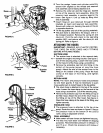

FIGURE 4.

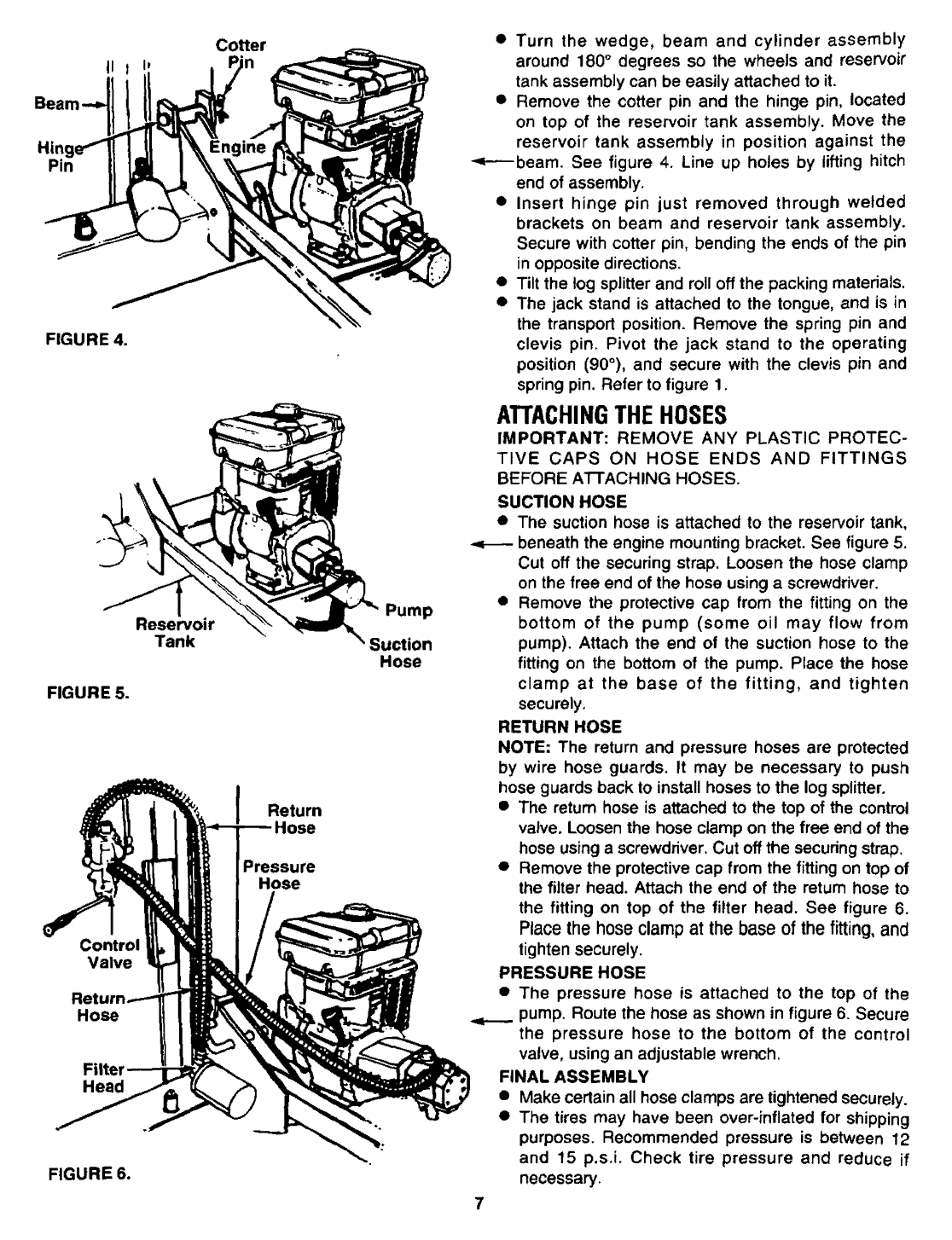

Reservoir

Tank

FIGURE 5.

Control

Valve

Hose

FIGURE 6.

Cotter

Return

Pressure

Hose

Pump

Suction

Hose

• Turn the wedge, beam and cylinder assembly

around 180° degrees so the wheels and reservoir

tank assembly can be easily attached to it.

• Remove the cotter pin and the hinge pin, located

on top of the reservoir tank assembly. Move the

reservoir tank assembly in position against the

-,i----beam. See figure 4. Line up holes by lifting hitch

end of assembly,

• Insert hinge pin just removed through welded

brackets on beam and reservoir tank assembly.

Secure with cotter pin, bending the ends of the pin

in opposite directions.

• Tilt the tog splitter and roll off the packing materials.

• The jack stand is attached to the tongue, and is in

the transport position. Remove the spring pin and

clevis pin. Pivot the jack stand to the operating

position (90°), and secure with the clevis pin and

spring pin. Refer to figure 1.

ATTACHINGTHEHOSES

IMPORTANT: REMOVE ANY PLASTIC PROTEC-

TIVE CAPS ON HOSE ENDS AND FITTINGS

BEFORE A1 I'ACHING HOSES.

SUCTION HOSE

• The suction hose is attached to the reservoir tank,

beneath the engine mounting bracket. See figure 5.

Cut off the securing strap. Loosen the hose clamp

on the free end of the hose using a screwdriver.

• Remove the protective cap from the fitting on the

bottom of the pump (some oil may flow from

pump). Attach the end of the suction hose to the

fitting on the bottom of the pump. Place the hose

clamp at the base of the fitting, and tighten

securely.

RETURN HOSE

NOTE: The return and pressure hoses are protected

by wire hose guards. It may be necessary to push

hose guards back to install hoses to the log splitter.

• The return hose is attached to the top of the control

valve. Loosen the hose clamp on the free end of the

hose using a screwdriver. Cut off the securing strap.

• Remove the protective cap from the fitting on top of

the filter head. Attach the end of the return hose to

the fitting on top of the filter head. See figure 6.

Place the hose clampat the base of the fitting, and

tighten securely.

PRESSURE HOSE

• The pressure hose is attached to the top of the

pump. Route the hose as shown in figure 6. Secure

the pressure hose to the bottom of the control

valve, using an adjustable wrench.

FINAL ASSEMBLY

• Make certain all hose clamps are tightened securely.

• The tires may have been over-inflated for shipping

purposes. Recommended pressure is between 12

and t5 p.s.i. Check tire pressure and reduce if

necessary.