GENERALRECOMMENDATIONS Hex Bolts

&

WARNING: ALWAYS STOP THE ENGINE

AND DISCONNECT THE SPARK PLUG

WIRE BEFORE PERFORMING ANY MAIN-

TENANCE OR ADJUSTMENTS.

Check all nuts, bolts and hose clamps periodically to

make certain they are tightened securely.

LOGSPLITTER

RESERVOIR FLUID

Check the hydraulic fluid level in the log splitter reser-

voir tank before each use. Fluid level should be 1-1/2"

to 2" from the top of the tank.

Change the hydraulic fluid in the reservoir every 100

hours of operation. Disconnect the suction hose from

the bottom of the reservoir tank, and drain the fluid

into a suitable container. Refill using only Dexron II

automatic transmission fluid, as instructed in the

BEFORE INITIAL USE section of this manual. Also,

make certain to change the hydraulic filter.

NOTE: Drain the fluid and flush the reservoir tank and

hoses with kerosene whenever any repair work is per-

formed on the tank, hydraulic pump or valve.

Contaminants in the fluid will damage the hydraulic

components (should be performed by your SEARS

Service Center).

WARNING: USE EXTREME CAUTION

WHEN WORKING WITH KEROSENE, AS

IT IS AN EXTREMELY FLAMMABLE

FLUID.

Wedge

Plate

Gib

"Back _.

Plate

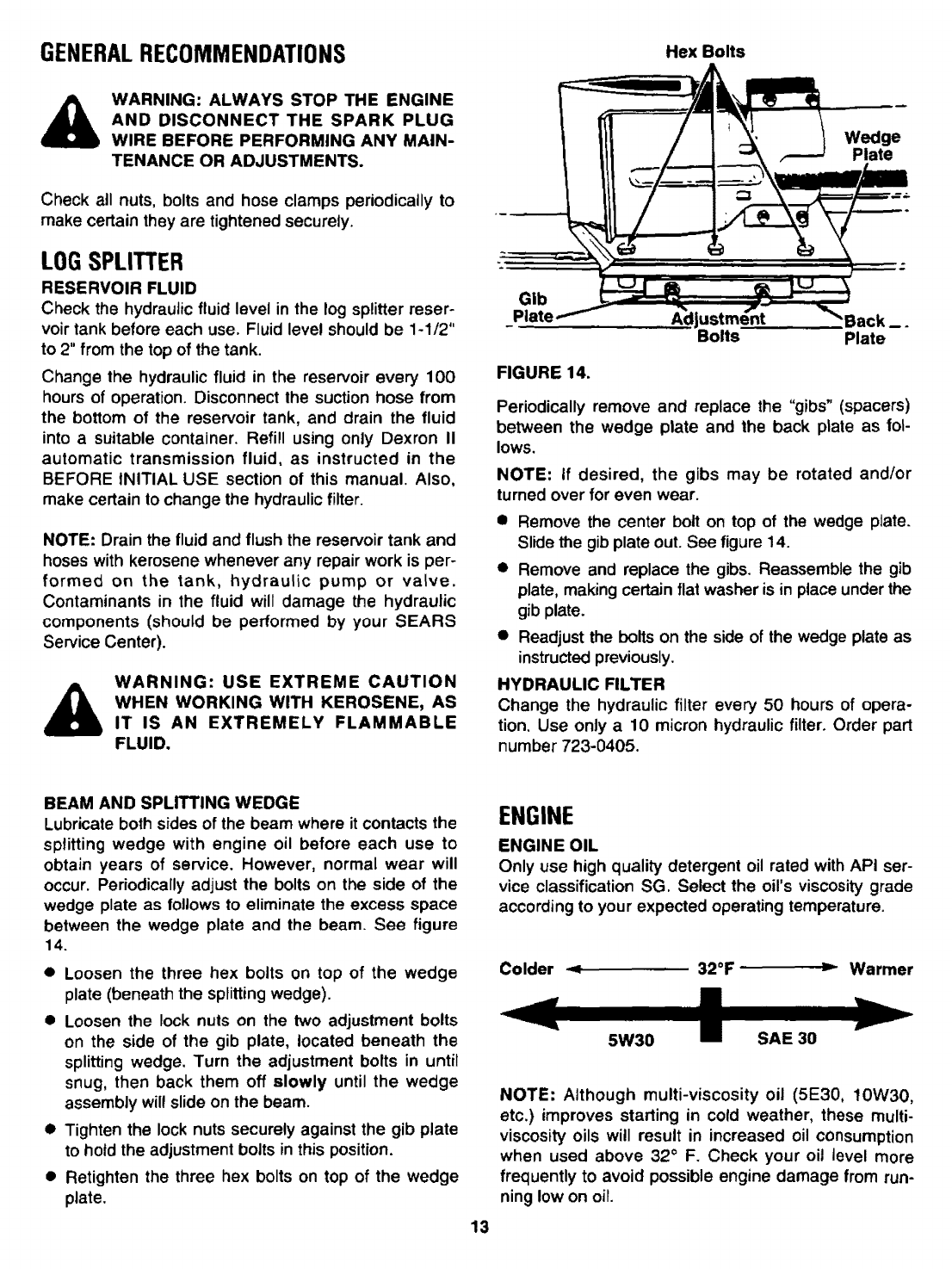

FIGURE 14.

Periodically remove and replace the "gibs" (spacers)

between the wedge plate and the back plate as fol-

lows.

NOTE: If desired, the gibs may be rotated and/or

turned over for even wear.

• Remove the center bolt on top of the wedge plate.

Slide the gib plate out. See figure 14.

• Remove and replace the gibs. Reassemble the gib

plate, making certain flat washer is in place under the

gib plate.

• Readjust the bolts on the side of the wedge plate as

instructed previously.

HYDRAULIC FILTER

Change the hydraulic filter every 50 hours of opera-

tion. Use only a 10 micron hydraulic filter. Order part

number 723-0405.

BEAM AND SPLITTING WEDGE

Lubricate both sides of the beam where it contacts the

splitting wedge with engine oil before each use to

obtain years of service. However, normal wear will

occur. Periodically adjust the bolts on the side of the

wedge plate as follows to eliminate the excess space

between the wedge plate and the beam. See figure

14.

• Loosen the three hex bolts on top of the wedge

plate (beneath the splitting wedge).

• Loosen the lock nuts on the two adjustment bolts

on the side of the gib plate, located beneath the

splitting wedge. Turn the adjustment bolts in until

snug, then back them off slowly until the wedge

assembly wil! slide on the beam.

• Tighten the lock nuts securely against the gib plate

to hold the adjustment bolts in this position.

• Retighten the three hex bolts on top of the wedge

plate.

ENGINE

ENGINE OIL

Only use high quality detergent oil rated with API ser-

vice classification SG. Select the oil's viscosity grade

according to your expected operating temperature.

Colder < 32°F "' = Warmer

13

NOTE: Although multi-viscosity oil (5E30, 10W30,

etc.) improves starting in cold weather, these multi-

viscosity oils will result in increased oil consumption

when used above 32 ° F. Check your oil level more

frequently to avoid possible engine damage from run-

ning low on oil.