MAINTENANCE AND REPAIR INSTRUCTIONS

16

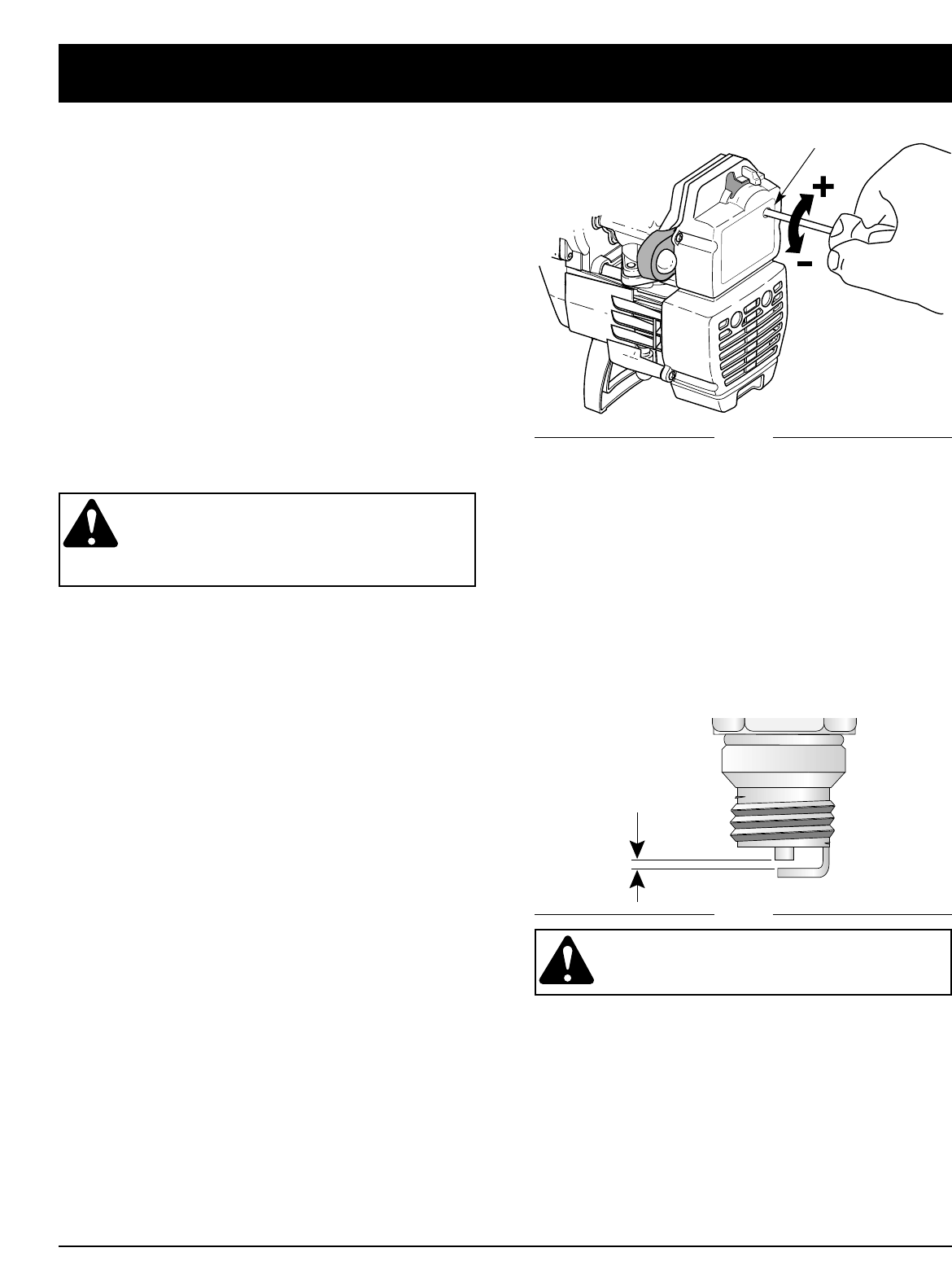

REPLACING THE SPARK PLUG

Use a Champion RDJ7Y spark plug (or equivalent). The

correct air gap is 0.020 in. (0.5 mm.). Remove the plug

after every 50 hours of operation to check its condition.

1. Stop the engine and allow it to cool. Grasp the plug

wire firmly and pull the cap from the spark plug.

2. Clean dirt from around the spark plug. Remove the

spark plug from the cylinder head by turning a 5/8 in.

socket counterclockwise.

NOTE: Replace cracked, fouled or dirty spark plug.

3. Set the air gap at 0.020 in. (0.5 mm.) using a feeler

gauge (Fig. 27).

0.020 in.

(0.5 mm.)

Fig. 27

CAUTION: Do not sand blast, scrape, or

clean electrodes. Grit in the engine could

damage the cylinder.

4. Install a correctly gaped spark plug in the cylinder

head. Tighten by turning the 5/8 in. socket clockwise

until snug.

If using a torque wrench torque to;

110-120 in.•lb.. (12.3-13.5 N•m).

Do not over tighten.

CARBURETOR SETTING

The idle speed adjuster of the engine is adjustable

through the Air filter/muffler cover (Fig 26).

NOTE: Careless adjustments can seriously damage your

unit. An authorized service dealer should make

carburetor adjustments.

Check Fuel Mixture

Old and/or improperly mixed fuel is usually the reason

for the unit not running properly. Drain and refill the tank

with fresh, properly mixed fuel prior to making any

adjustments. Refer to Oil and Fuel Information, Pg. 11.

Clean Air Filter

The condition of the air filter is important to the

operation of the unit. A dirty air filter will restrict air flow

and change the air/fuel mixture. This is often mistaken

for an out of adjustment carburetor. Check the condition

of the air filter before adjusting the idle speed adjuster.

Refer to

Air Filter Maintenance Pg. 14.

Adjust Idle Speed Adjuster

WARNING: This unit will need to be running

during idle speed adjustment. Wear

protective clothing and observe all safety

instructions to prevent serious personal

injury.

If after checking the fuel mixture and cleaning the

air filter the engine still will not idle, adjust the idle speed

screw as follows.

1. Start the engine and let it run at a high idle for a

minute to warm up. See Starting/Stopping

Instructions, Pg. 12.

NOTE: Ensure the tines are not in contact with the

ground when adjusting the idle.

2. Release the throttle control and let the engine idle. If

the engine stops, insert a small phillips or flat blade

screwdriver into the hole in the air filter/muffler cover

(Fig. 26). Turn the idle speed screw in, clockwise,

1/8 of a turn at a time (as needed) until the engine

idles smoothly.

NOTE: The tines should not rotate when the engine

idles.

3. If the tines rotate when the engine idles, turn the idle

speed screw counterclockwise 1/8 of a turn at a

time (as needed), to reduce idle speed.

Checking the fuel mixture, cleaning the air filter, and

adjusting the idle speed screw should solve most engine

problems.

If not and:

• The engine will not idle,

• The engine hesitates or stalls on acceleration,

• There is a loss of engine power,

have the carburetor adjusted by an authorized service

dealer.

Idle Speed Adjuster

Fig. 26