MAINTENANCE

OIL CHANGE

Refer engine manufacturers’ instructions.

1. Place the machine on a level surface. Start and run

the engine for a period to warm the oil.

Fig. 8

2. Fit the drain tube to the drain fitting. Fig. 8

3. Place an oil pan under the end of drain tube.

4. Open the drain fitting about 1 turn and allow the oil

to drain completely.

5. Retighten the drain fitting and refill the sump with

new oil. For correct viscosity and service

classification, refer to the engine manufacturers’

instructions.

SPARK PLUG

The spark plug gap gradually increases during engine

running and should be checked periodically and

whenever the engine malfunctions.

1. Clean around the spark plug area so that dirt will not

enter the engine when the spark plug is removed.

2. Disconnect the spark plug lead and remove the spark

plug.

3. Check the condition of electrodes and ensure there is

no damage to insulator.

4. Carefully clean the spark plug. Do not grit blast.

5. Set the gap between 0.7mm to 0.8mm.

6. Install the spark plug in the engine and tighten.

COOLING SYSTEM

The Ranger has an air cooled 4 stroke engine. It must

be cleared frequently. Remove any build up of grass,

dirt or other debris from the

1. Cylinder

2. Cylinder head cooling fins

3. Cooling air intake screen

4. Carburettor governor levers and linkages.

This will ensure adequate cooling and correct engine

speed.

THROTTLE CONTROL

Proper choke operation is dependant on the

adjustment of remote controls –

1. Loosen the outer cable clamp screw on engine.

2. Set the throttle control to choke position.

3. Adjust the outer cable under clamp plate so that

choke is operated.

4. Tighten the clamp plate screw and check

(a) Choke does not operate in fast position,

(b) Stop switch operates correctly.

CARBURETTOR ADJUSTMENT

The carburettor has been factory set and should only

require occasional fine tuning.

Refer to Engine Manufacturer’s Owner’s Manual for

details adjustment procedures.

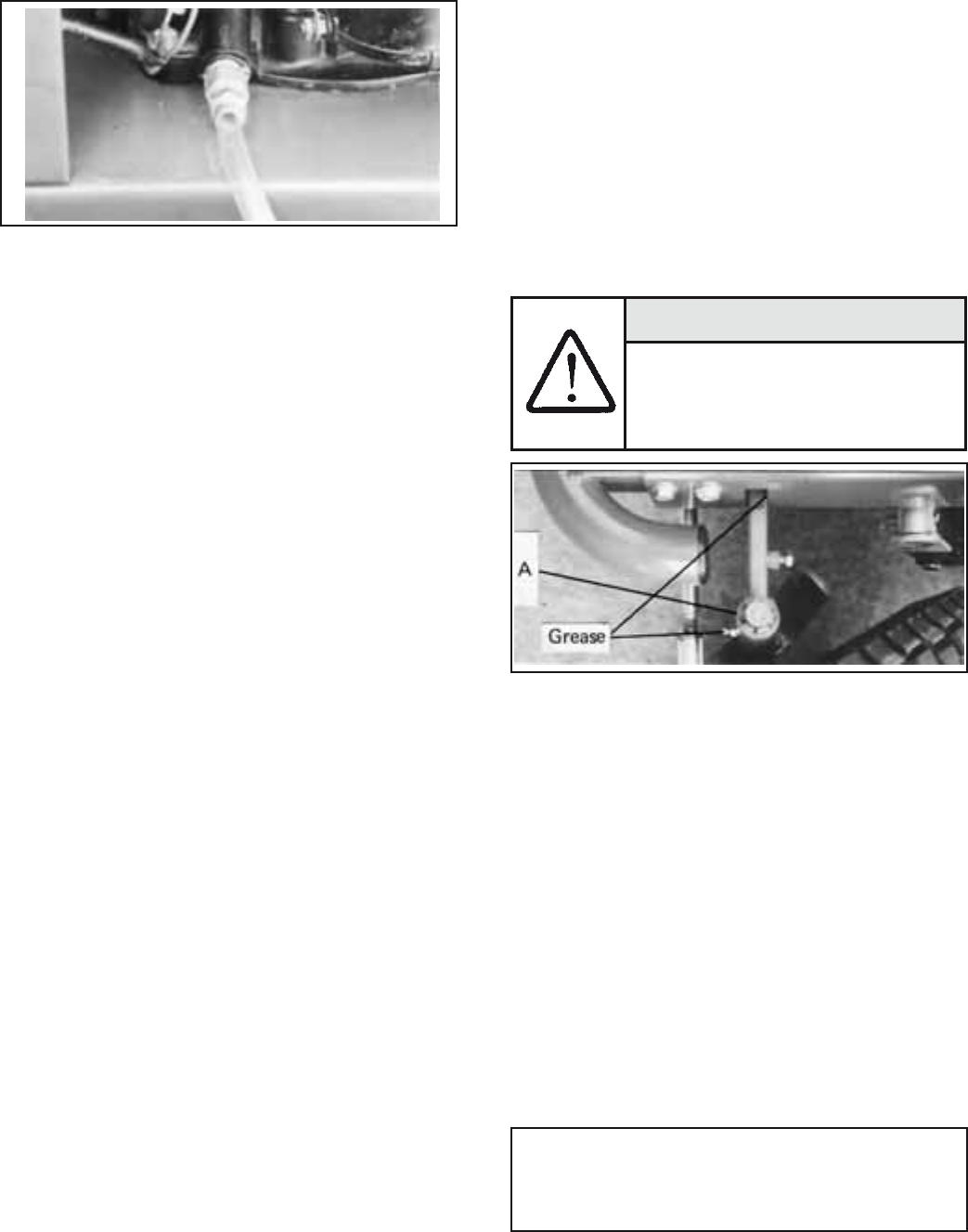

Fig. 11

LUBRICATION GENERAL

Using General Purpose Grease – (Every 25 hours)

Grease nipples on front wheel pivots. Fig. 11

Cam plate bearing area. Fig. 26

Front Axle beam guides.

Grease nipples on steering pivot blocks. Fig. 21

Steering gears. Fig. 21

Grease nipples on engagement lever pivot.

Steeing pivot blocks. Fig. 23

Using Clean Engine Oil –

Jockey pivot arms

Throttle control cable.

Drive Chain. Fig. 23

Cutter drive lever pivot.

Clutch/Brake pedal pivot. Fig. 15

Tie rod ball ends. Fig. 11

All connecting rod pivots points.

NOTE:

All ball bearings are sealed and require no

maintenance.

8

MAINTENANCE

CUTTING UNIT

Remove spark plug lead and disengage cutter drive

before working on cutter unit, to prevent accidental

starting of the engine.

Before using the machine always inspect cutting unit to

ensure that the cutting disc, blades and blade fittings are

not worn or damaged.

Always check after striking a solid object. Do not

operate machine when unusual vibration occurs.

Replace worn or damaged blades in sets to preserve

balance.

Remove any build-up of grass or clogging within the

cutting unit, discharge chute or stone guard.

CUTTERHEAD REMOVAL

Fig. 12

1. Disconnect push rods & brake rod. Fig. 12

2. Remove the tensioning spring. A loop has been

provided on the spring to assist in this operation. Fig.

12

3. Slide cutterback towards back of machine and

remove belt from around cutterdeck pulley.

4. Undo large retaining washer bolts (A) Fig. 12 This

will allow front of deck to be lowered to ground.

5. Slide cutterdeck forward. This will allow the rear to

be lowered to the ground and be slid from under the

machine.

6. Replace in reverse order.

NOTE:

To remove cutterdeck belt from machine, the

belt guard has to be moved away from the

drive pulley to allow the belt to be removed

from the V-groove and the cutterhead lifting

rod is to be disengaged from the cutterhead

selection arm assembly to allow belt to be

drawn out.

WHEEL REMOVAL

Fig. 13 Fig. 14

Front –

1. Chock the rear wheels and remove the front axle nut.

Fig. 13

2. Raise the front of the machine.

3. Slide the wheel from the shaft.

4. Replace in reverse order.

5. Re-tighten the axle nut firmly.

Rear –

1. Chock the front wheels and raise the rear of the

machine.

2. Remove the four wheel nuts.

3. Slide the wheel from the hub. Fig. 14

4. Refit the wheel to hub.

5. Replace the wheel nuts and tighten.

BRAKE CALIPER ADJUSTMENT

Fig. 15

1. Loosen locknut ‘A’ Fig. 15

2. Adjust Bolt ‘B’ till brake calliper ‘C’ touches brake

Disc.

3. Re-tighten locknut ‘A’.

BRAKE ARM ADJUSTMENT

1. Check that brake calliper is correctly adjusted.

2. Adjust locknut ‘E’ Fig. 15. Till brake arm ‘D’ Pad

comes into contact with disc.

3. Check operation of brake to ensure park brake can be

applied, and brake operates correctly.

9

WARNING

Always deflate tyre before moving

rim nuts on front wheel only.

CAUTION

Never tamper with the engine

governor setting. Changing of

engine governor speed will

void engine warranty.

2303 Current Artwork 7-2003 18/5/06 2:11 PM Page 10