11

www.remingtonpowertools.com

ENGLISH

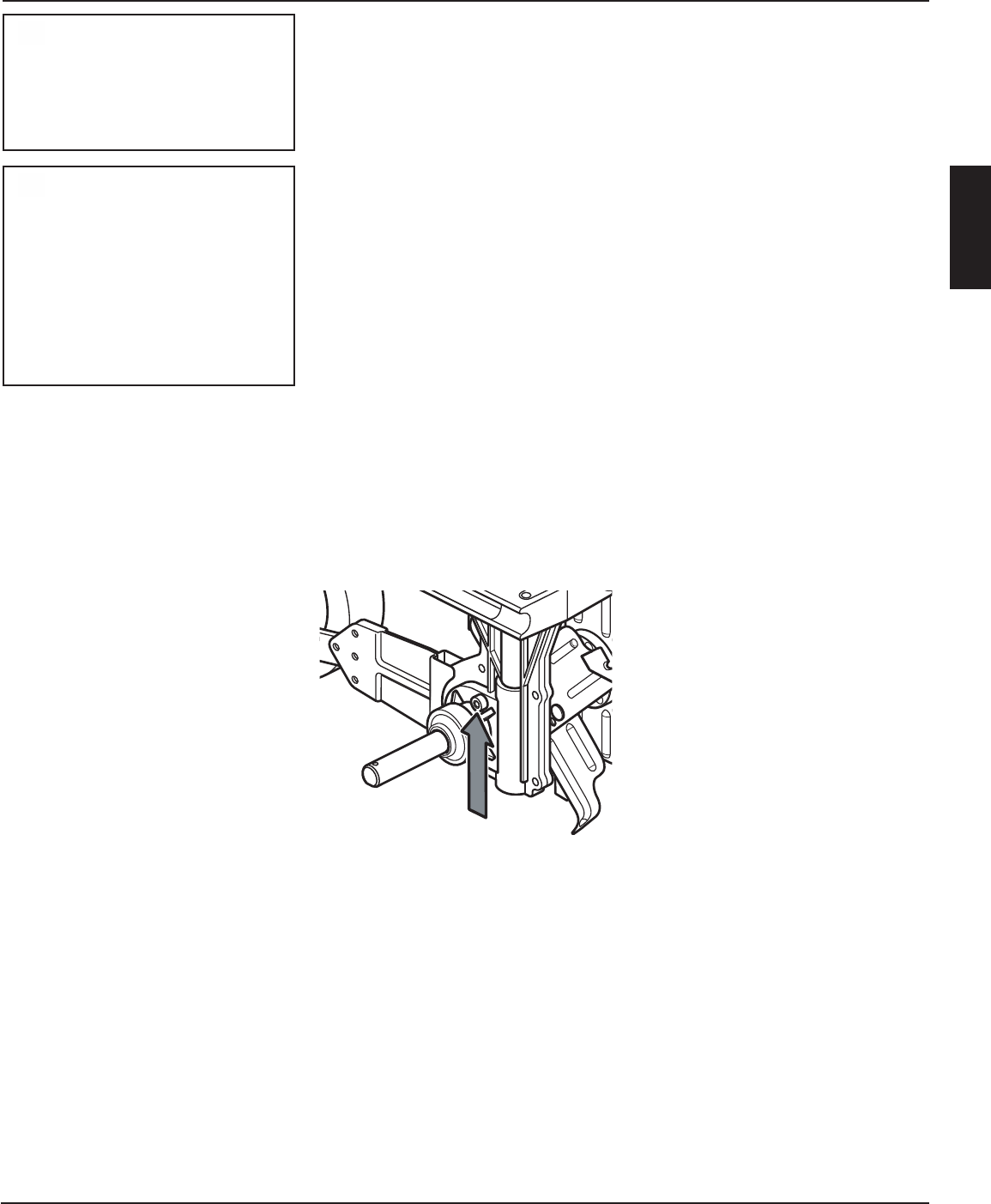

Figure 13- Grease Filler Screw

Grease Filler

Screw

CHECKING TRANSMISSION

LUBRICANT

1. Unplug tiller from power source.

2. Locate the grease fi ller screw located

above the tine shaft on the right side of

the transmission (see Figure 13).

3. Lay the tiller on its left side. Remove

the right side tine sets for easy access

to grease fi ller screw. See Tine Removal

and Installation.

4. Clean the transmission to prevent dirt and

debris from entering the transmission.

5. Using a Phillips head screwdriver, re-

move the grease fi ller screw from the

transmission case.

6. If grease is not visible in the hole,

add a high-quality, automotive-grade,

petroleum-based grease using standard

grease gun. Place the nozzle of the

grease gun fi rmly against the rim of

the hole and add grease until it begins

to seep out around the edge of the

nozzle.

7. Reinstall the grease fi ller screw and

wipe away any excess grease.

8. Reassemble the tine sets. See Tine

Removal and Installation.

CLEANING TILLER

1. To clean front and rear cover and

fender, use a soft cloth dampened with

a mild soap and water mixture. Do not

spray or pour water directly onto the

front or rear cover. Wipe the front and

rear covers and fender with the damp-

ened cloth.

2. To remove soil and debris from the

tines and transmission, use a stiff brush

or a dampened cloth. Do not spray or

pour water directly onto tiller.

3. For easier cleaning, remove the tines

from the tine shaft. See Tine Removal

and Installation.

4. Once cleaned, wipe the tine shaft dry

and apply a light coat of oil to the shaft

before reinstalling the tines.

WARNING: When cleaning

tiller:

• Do not submerge tiller in any

liquids.

• Do not use products that

contain ammonia, chlorine, or

abrasives.

• Do not use chlorinated cleaning

solvents, carbon tetrachloride,

kerosene, or gasoline.

WARNING: Unplug tiller from

power source before cleaning or

servicing. Severe injury or death

could occur from fi re, electrical

shock, or body contact with mov-

ing tines.

CLEANING AND MAINTENANCE

OTHER SUGGESTED

LUBRICATION POINTS

Handlebar Adjustment Knobs: Oc-

casionally spray a silicone type lubricant

around the saddle bolts.

Tine Shaft: After each use, remove the

tines, clean the tine shaft with fi ne sandpaper

and apply a light coat of oil to the tine shaft.

This will make future tine installation and

removal easier.