/ iii ii]1111111ilJl/ J/irll i iiii iiiiiiiii

C. STARTER ROPE

• A starter rope that breaks next to the pulley can be

repaired.

• Replacethe starter ropeifthe ropebreaks more than

2-3 inches away from the pulley as the rope will be

too short to repair properly.

A WARNING

Always wear eye protection when servicing the

starter rope. The recoil spring beneath the pulley

is under tension. If the spring pops out, serious

injury can result.

1

NOTE:The recoilspring,locatedbeneaththe pulley,

is under tension. If the spring pops out, it will

require considerable time and effort the

reinstall. For this reason, you may want to leta

qualifiedservicedealerhandlethisrepair.Ifyoudo

trytorepairthestarterrope andtherecoilspringpops

out,takethe unitto a qualifiedservice dealer.

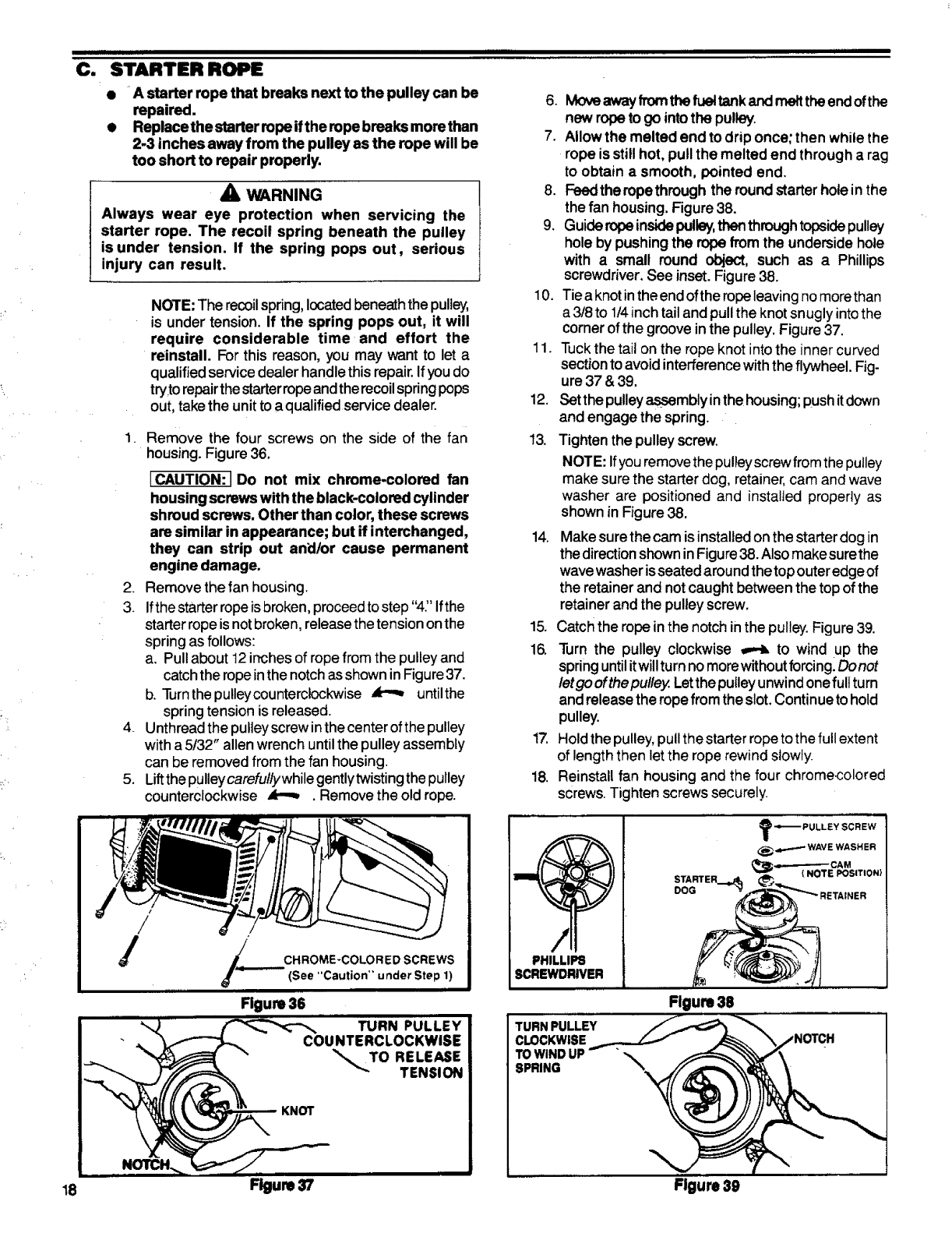

Remove the four screws on the side of the fan

housing. Figure 36,

ICAUTION:I Do not mix chrome-colored fan

housing screwswith the black-colored cylinder

shroud screws. Other than color, these screws

are similar in appearance; butif interchanged,

they can strip out and/or cause permanent

engine damage.

2. Remove thefan housing.

3. Ifthe starterrope isbroken, proceedtostep "4:' Ifthe

starterrope isnotbroken, release thetension on the

spring as follows:

a. Pull about 12inches of rope from the pulley and

catchthe ropein the notch asshown in Figure37.

b. Turnthepulleycounterclockwise _ untilthe

spring tension is released.

4_ Unthread the pulleyscrew in thecenter ofthe pulley

with a 5/32" allenwrench untilthe pulley assembly

can be removed from the fan housing.

5. LiftthePUlleycarefu//ywhile gentlytwisting the pulley

counterclockwise _ . Remove the old rope.

/ CHROME-COLORED SCREWS

'-'-- (See "Caution" under Step 1)

Figure36

TURN PULLEY

TO RELEASE

TENSION

6. Moveaway from the fueltank andmetttheend ofthe

new rope to go intothe pulley.

7. Allow the melted end to drip once; then whilethe

rope is stillhot, pull the melted end through a rag

to obtain a smooth, pointed end.

8. Feedthe ropethrough the round starterhole in the

the fan housing. Figure 38.

9. Guide rope insidepulley,thenthrough topsidepulley

hole by pushing the rope from the underside hole

with a small round object, such as a Phillips

screwdriver. See inset. Figure 38.

10. Tie aknot inthe end oftherope leaving nomorethan

a 3/8to 1/4inch tail and pull the knot snugly intothe

corner of the groove in the pulley. Figure 37.

11. Tuckthe tail on the rope knot into the inner curved

section to avoid interference with the flywheel. Fig-

ure 37 & 39.

12. Settheputleyassemblyinthehousing; push itdown

and engage the spring.

13. Tighten the pulley screw.

NOTE: Ifyou removethepulleyscrew fromthepulley

make sure the starter dog, retainer, cam and wave

washer are positioned and installed properly as

shown in Figure 38,

14. Make surethe cam isinstalled on the starter dog in

thedirection shown in Figure38.Alsomake surethe

wave washer isseated around the top outeredge of

the retainer and not caught between the top of the

retainer and the pulley screw.

15. Catch the rope in the notch in the pulley. Figure 39.

16. Turn the pulley clockwise _ to wind up the

springuntilitwillturn no morewithout forcing.Donot

letgo ofthepulley. Letthe pulley unwind onefult turn

and releasethe rope from the slot.Continue tohold

pulley.

17. Holdthe pulley, pull thestarter rope to thefull extent

of length then let the rope rewind slowly.

18. Reinstall fan housing and the four chrome_colored

screws. Tighten screws securely.

STARTER_

DOG "#

PHILLIPS

SCREWDRIVER

TURN PULLEY

CLOCKWISE

TO WIND

SPRING

Figure 38

18 Figure 37 Route 39