54

MAINTENANCE

Spark Plug

Spark Plug Inspection and Replacement

3. Clean any dirt from around the base of the spark plug.

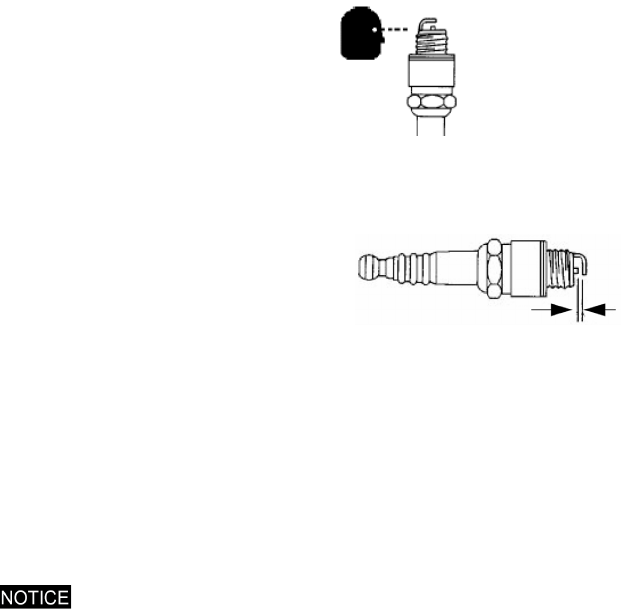

4. Using the provided park plug wrench (B), remove the spark plug.

5. Inspect the electrode for wear

and carbon buildup. Look for a

sharp outer edge with no

rounding or erosion of the

electrode.

6. Inspect spark plug. Replace if electrodes are worn or if insulator is

cracked, chipped, or fouled.

7. Clean the spark plug with a wire brush if it is to be reused.

8. Using a wire-type feeler gauge,

measure the spark plug

electrode gap. If necessary,

correct the gap by carefully

bending the side electrode. The

gap should be 0.028-0.031in

(0.7-0.8mm). Correct as

necessary by carefully bending

the side electrode.

9. Ensure the spark plug sealing washer is in good condition and

thread the spark plug in by hand to prevent cross-threading.

10. After a new spark plug has been seated by hand, it should be

tightened 1/2 turn with a wrench to compress the sealing washer. If

a used plug is being reinstalled, it should only require 1/8 to 1/4 turn

after being seated.

A loose spark plug can overheat and damage the engine. Over tightening

the spark plug can damage the plug threads.

Never use a spark plug with an improper heat range.

11. Re-install the spark plug cap and close the service door.

Inspect electrode

for wear and

buildup

Spark plug gap