4

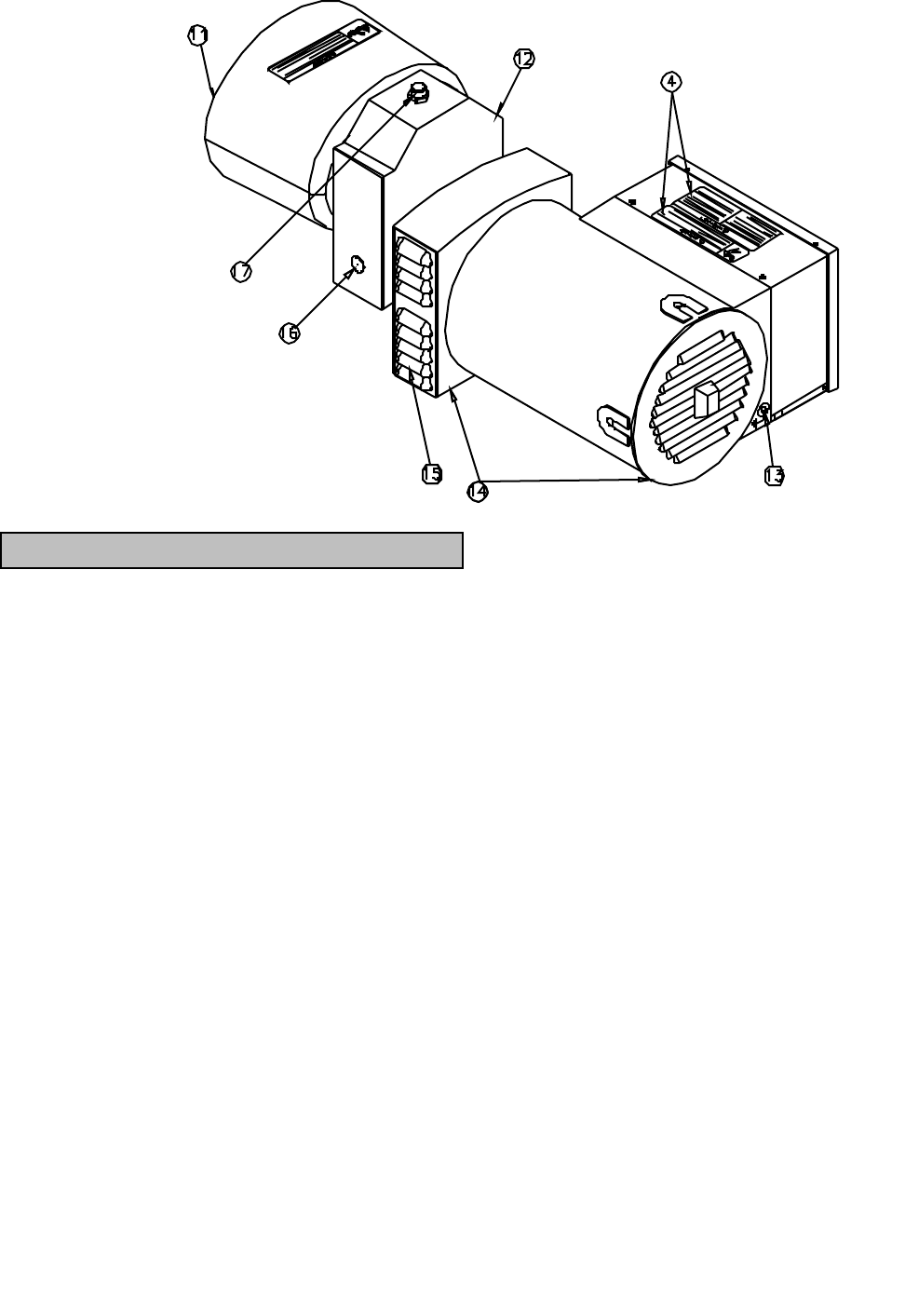

GENERATOR FEATURES

References 1-3 Circuit Breakers.

• Reference 1 - two 50A push-to-reset circuit

breakers.

• Reference 2 - one 30A push-to-reset circuit

breaker.

• Reference 3 - two 20A push-to-reset circuit

breakers.

References 4 - Warning Decals. Read and

follow all warnings.

References 5 - 1 3/8” Diameter 6 Spline Input

Shaft. 540 RPM. PTO driveline is available from

Northern, Item #165936.

References 6 - Oil Drain Plug. Change oil

after the first 50 hours of use, then after every 500

hours.

References 7 - Voltmeter. Voltmeter needle

should be in green area during all generator load

conditions. The black line in the center on the

green area indicates 120V. During no load

conditions, the needle should be at or above the

black line.

References 8-9 120V Receptacles.

• Reference 8 - 120V Receptacle. The

generator has a control panel with two 120V 20A

straight blade receptacle duplexes (two receptacles

in a common housing). National Electrical

Manufacturer’s Association (NEMA) number is 5-

20R.

• Reference 9 - This twistlock receptacle is a

120V 30A receptacle, NEMA number L5-30R. This

receptacle accepts NEMA plug number L5-30P,

which is supplied with the generator.

Reference 10 - 120/240V Receptacle. This

straight blade receptacle is 120/240V 50A. This

receptacle accepts a NEMA plug number 14-50P.

ALWAYS use grounded male plugs. The

neutral line of the generator is mechanically

grounded to the frame. Matching NEMA male

plugs must always be used.

References 11 - Shield. Plastic implement

shield. NEVER operate generator without shield in

place.

Reference 12 - Gear Box. Cast iron frame. 1:7

gear ratio.

Reference 13 - Grounding Screw. Ground the

generator via the ground screw, to a copper pipe or

rod that is driven into moist soil.

Reference 14 - Mounting Holes. Use these

three locations to mount the generator head in

place with 7/16” grade 5 bolts. Mounting plates

(item #165935) for mounting generator to a cement

pad are available through Northern and the

NorthStar parts catalog.

Reference 15 - Fan Vents. Never block the

vent slots or insert objects through the slots. The

closest object should be at least 3 feet away from

the vents.

Reference 16 - Oil Level Sight. When oil is

even with the red dot, the oil level is correct. Check

oil level daily. Sight is mounted on the gear box

service panel. If panel is removed for whatever

reason, reseal using Dow Corning sealant #732.

Fi

g

ure 2

(

Ref. 10-16

)

00295