SP 1 SAW CE— OPERATION AND PARTS MANUAL — REV. #3 (06/09/08) — PAGE 27

Drive Belt

Refer to page 16 of this manual for Drive Belt adjustment

procedures and Removal and Replacement procedures.

See the engine manual supplied with your

machine for appropriate engine

maintenance schedule and troubleshooting

guide for problems.

MQ STREET PRO 1 CE SAW — MAINTENANCE

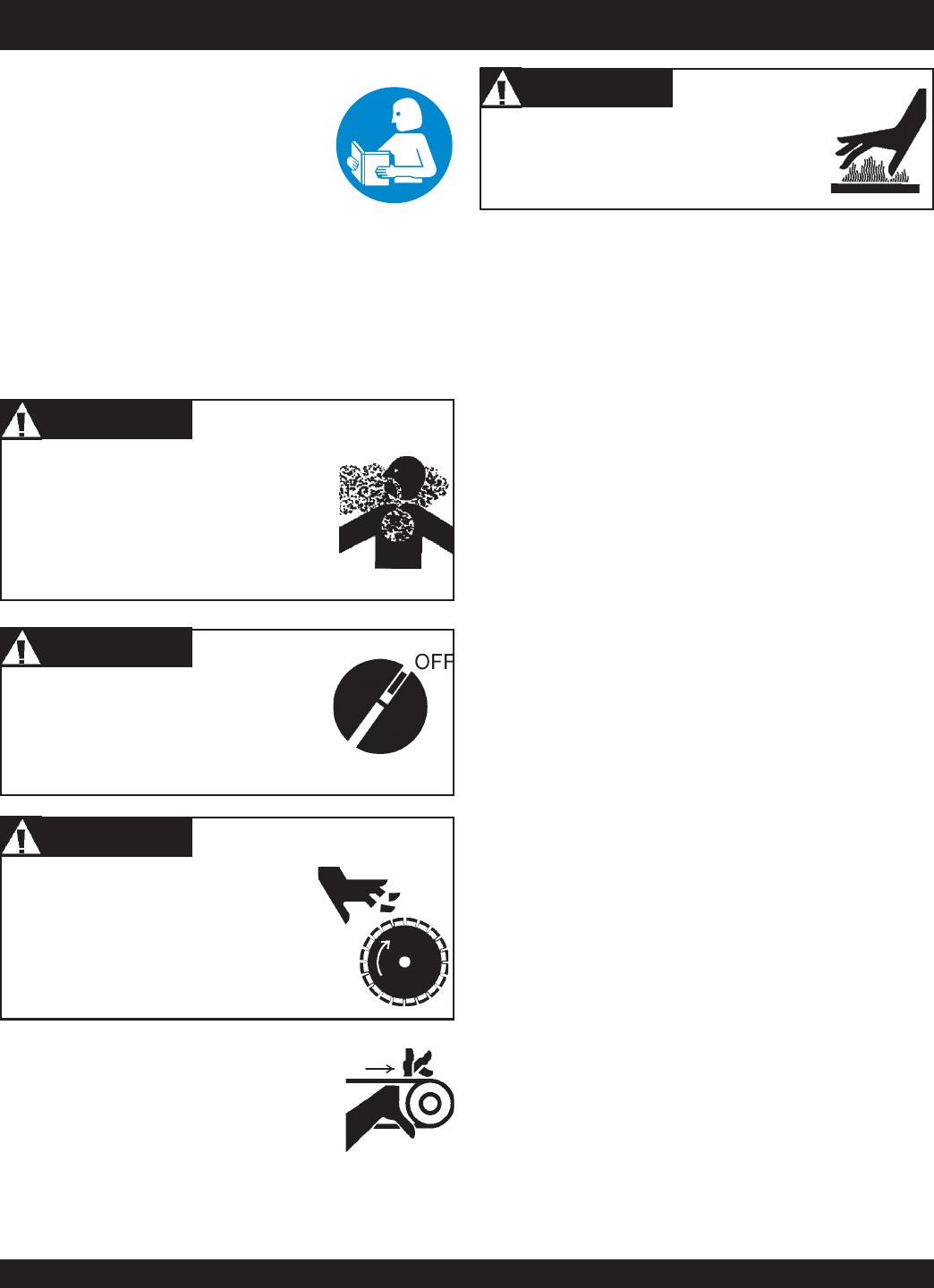

ALWAYS allow the engine to cool before

servicing. NEVER attempt any maintenance

work on a

hot!

engine.

■

REMOVING

or

INSTALLING

blades

■

ADJUSTING

front or rear pointers

■

LUBRICATING

any components

■

REMOVING

engine mounting bolts

■

INSPECTING, ADJUSTING, OR

REPLACING

drivebelt, spindle, spindle bearings or

ANY

engine part

■

REMOVING

blade or belt guards

Saw Blade Removal and Installation

See page 19.

Chassis Lubrication

■

Spindle Bearings - Two zerk fittings are located up under

the lower-front of the saw. Lubricate before daily use.

Use a good quality extreme pressure grease. Check and

lubricate more often if unit is under heavy use. Do not

overfill bearings. Overfilling can damage the grease seals.

This can result in bearing exposure to dirt and

contaminants which can then shorten the life of the

bearings. Excess grease can also drip onto the cutting

surface.

MAINTENANCE

CAUTION

General Cleanliness

Clean the machine daily. Remove all dust and slurry build up.

If the saw is steam cleaned, ensure that lubrication is accom-

plished AFTER steam cleaning operations.

Engine check:

Check daily for any oil and/or fuel leakage, thread nut & bolt

tightness, and overall cleanliness.

ALWAYS ensure that both ENGINE ON/

OFF switches (on the handlebar and on

the engine) are in the "OFF" position, and

that the spindle has COMPLETELY

STOPPED ROTATING before performing

any of the the following operations:

CAUTION

Some maintenance operations may require

the engine to be run. Ensure that the mainte-

nance area is well ventilated. Exhaust con-

tains poisonous carbon monoxide gas that

can cause of unconsciousness and may re-

sult in DEATH.

Before servicing or inspection, ALWAYS

park the saw on a level surface with the

blade removed, and the handlebar En-

gine ON/OFF switch & Engine ON/OFF

switch in “OFF” position.

General maintenance practices are crucial to the

performance and longevity of your saw. The extreme

environments of sawing operations require routine

cleaning, lubrication, belt tensioning, and inspection for wear

and damage

DANGER

The following procedures devoted to maintenance can prevent

serious saw damage or malfunctioning.

WARNING

Engine air filter:

Replace air filter if dirty. See Engine Owner’s Manual for

detailed information.

General Engine Care

Engine oil:

Check daily. Inspect with blade removed and saw frame

level on a level surface. Keep the oil clean, and at the proper

servicing level (Figure 7). DO NOT OVERFILL! SAE 10W-

30 of SG is recommended for general use.