11

OPERATING INSTRUCTIONS

possible. Cutting to the left improves

the unit's cutting efficiency. Clippings

are thrown away from the operator.

• Slowly move the trimmer into and out of

the cutting area at the desired height.

Move either in a forward-backward or

side-to-side motion. Cutting shorter

lengths produces the best results.

• Trim only when grass and weeds are dry.

• The life of your cutting line is dependent

upon;

• Adherence of the listed trimming

techniques

• What vegetation is cut

• Where vegetation is cut

For example, the line will wear faster

when trimming against a foundation wall

as opposed to trimming around a tree.

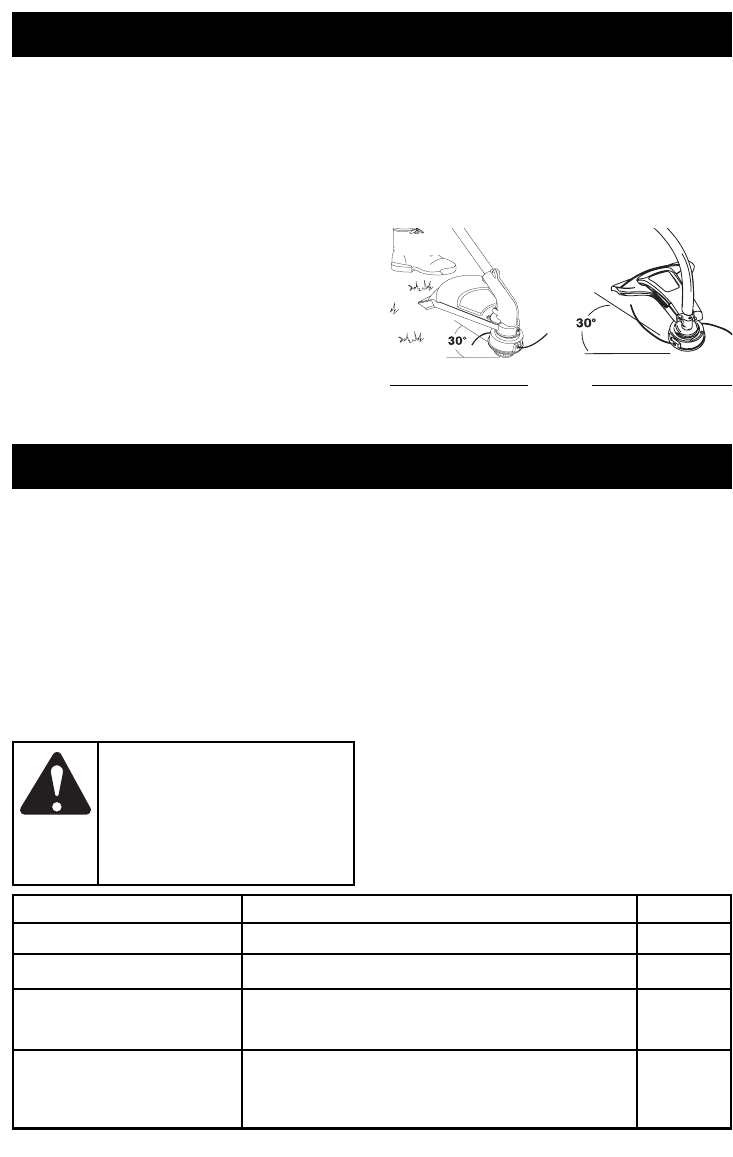

Fig. 11

BL100

BL150

DECORATIVE TRIMMING

Decorative trimming is accomplished by

removing all vegetation around trees,

posts, fences, etc.

Rotate the whole unit so that the cutting

attachment is at a 30° angle to the

ground (Fig. 11).

MAINTENANCE AND REPAIR INSTRUCTIONS

MAINTENANCE SCHEDULE

Perform these required maintenance

procedures at the frequency stated in the

table. These procedures should also be a

part of any seasonal tune-up.

NOTE: Some maintenance procedures

may require special tools or

skills. If you are unsure about

these procedures take your unit

to any non-road engine repair

establishment, individual or

authorized service dealer.

NOTE: Maintenance, replacement, or

repair of the emission control

devices and system may be

performed by any non-road engine

repair establishment, individual or

authorized service dealer.

In order to assure peak performance of your

engine, inspection of the engine exhaust

port may be necessary after 50 hours of

operation. If you notice lost RPM, poor

performance or general lack of acceleration,

this service may be required. If you feel your

engine is in need of this inspection, refer

service to any non-road engine repair

establishment, individual or authorized

service dealer for repair. DO NOT attempt to

perform this process yourself as engine

damage may result from contaminants

involved in the cleaning process for the port.

WARNING:

To prevent

serious injury, never perform

maintenance or repairs with unit

running. Always service and

repair a cool unit. Disconnect

the spark plug wire to ensure

that the unit cannot start.

FREQUENCY MAINTENANCE REQUIRED SEE

Before starting engine Fill fuel tank with fresh fuel p. 6

Every 10 hours Clean and re-oil air filter p. 13

Every 25 hours

Check and clean spark arrestor

Check spark plug condition and gap

p. 12

p. 12

Every 50 hours

Inspect exhaust port and spark arrestor

screen for clogging or obstruction to assure

maximum performance levels.

p. 14