6

Figure 1

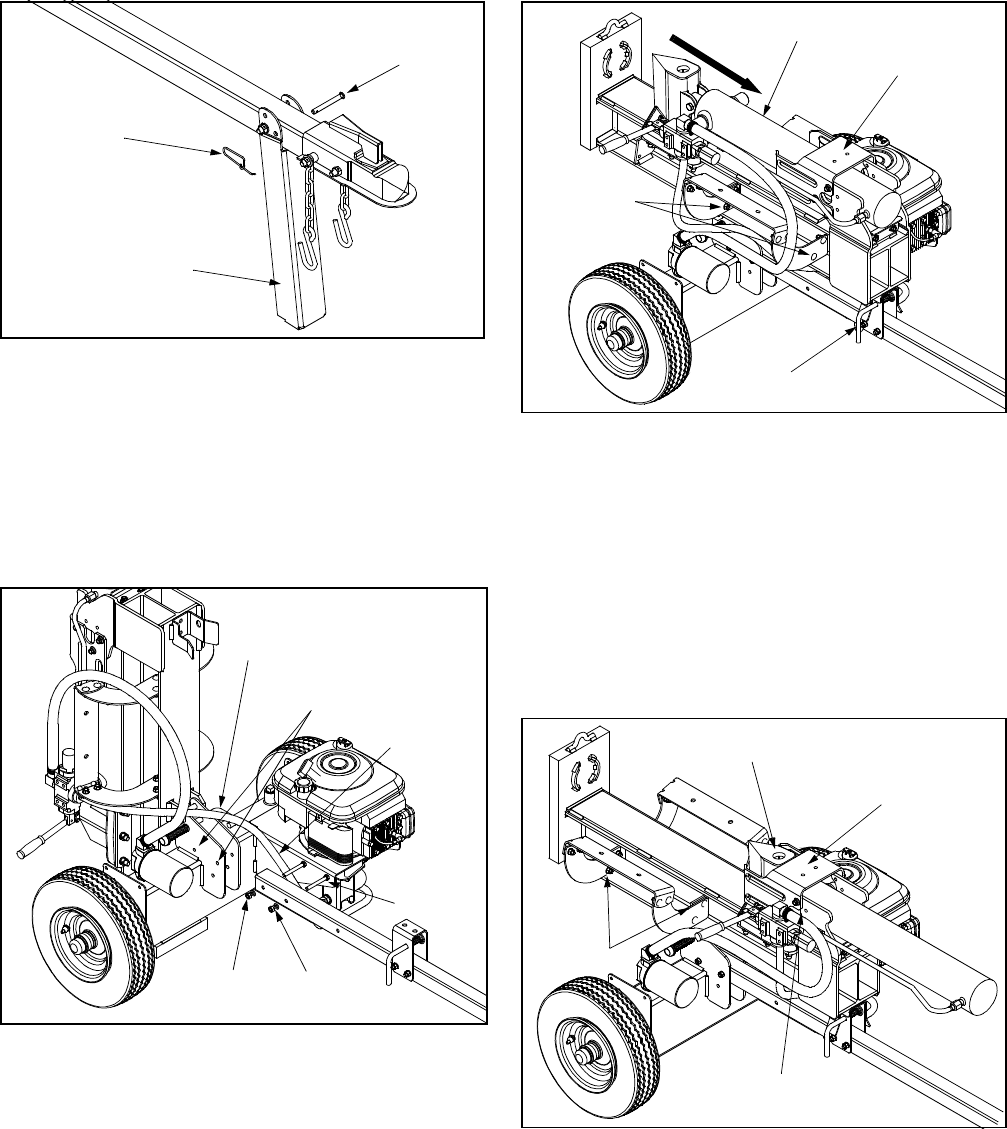

Attaching The Tongue (See Figure 2)

• With the log splitter still standing upright, remove

two hex bolts, lock washers, and hex nuts from the

end of the tongue assembly.

• Align the holes in the tongue with the holes in the

tank and secure with hardware just removed.

NOTE: High pressure hose must be above the

tongue assembly.

Figure 2

Connecting the Cylinder to Beam

• The log splitter is shipped with the beam in the

vertical position. Pull out the vertical lock rod, rotate

it back, and pivot the beam to the horizontal

position until it locks. See Figure 2 & Figure 3.

• Disconnect the dislodger from the beam weld

bracket by removing the six hex screws and flat

washers. See Figure 3.

• Disconnect the log cradle from the beam on the

side of the control valve.

• Lift and slide the cylinder up to the top of beam and

into the weld brackets.

Figure 3

• Attach the dislodger over the wedge assembly and

secure with the hardware previously removed to the

weld brackets. See Figure 4.

• Once the six hex screws are tighten, there may be

a slight gap between the dislodger and the weld

brackets. This gap is allowable.

• Reattach the log cradle to the side of the beam with

the control valve, aligning the ends of the cradle

with the beam flanges.

• Roll log splitter off the bottom crate.

Figure 4

Preparing The Log Splitter

• Lubricate the beam area where the splitting wedge

will slide with engine oil (DO NOT USE GREASE).

• Remove vented reservoir dipstick, which is located

in front of the engine on top of the reservoir tank.

See Figure 5.

Spring

Clip

Clevis

Pin

Jack Stand

(Operating Position)

Align With

Hex Bolts

Hex Nuts

Lock

Washers

These Holes

Vertical Lock

Pressure

Hose

Horizontal

Lock

Dislodger

Vertical Lock

Remove

Log Cradle

Wedge Assembly

Dislodger

Attach

Log Cradle

Weld Bracket Slot