11

Drain the fluid and flush the reservoir tank and hoses

with kerosene whenever any repair work is performed

on the tank, hydraulic pump or valve. Contaminants in

the fluid will damage the hydraulic components.

NOTE: The flushing the reservoir tank is recommended

to be performed by an authorized service dealer.

WARNING: Use extreme caution when

working with kerosene. It is an extremely

flammable fluid.

Hydraulic Filter

Change the hydraulic filter every 50 hours of operation.

Use only a 10 micron hydraulic filter. Order part number

723-0405.

Beam And Splitting Wedge

Lubricate both sides of the beam (where it comes into

contact with the splitting wedge) before each use with

engine oil. The wedge plate on the log splitter is

designed so the gibs on the side of the wedge plate can

be removed and rotated and/or turned over for even

wear.Make certain to readjust the adjustment bolts so

wedge moves freely, but no excess space exists

between the wedge plate and beam.

Hose Clamps

Check the hose clamps on the suction hose (attached

to side of the pump) for proper tightness before each

use. Check the hose clamps on the return hose at least

once a season.

Engine

Refer to the separate engine manual for all engine

maintenance instructions.

Flexible Pump Coupler

The flexible pump coupler is a nylon “spider” insert,

located between the pump and engine shaft. Over a

period of time, the coupler will harden and deteriorate.

Replacement is needed if you detect vibration or noise

coming from the area between the engine and the

pump. If the coupler fails completely, you will

experience a loss of power.

IMPORTANT:

Never hit the engine shaft in any manner,

as a blow will cause permanent damage to the engine.

When replacing the flexible pump coupler, proceed as

follows:

• Remove three nuts and lock washers that secure

the pump to the coupling shield. Two nuts are at the

bottom corners and one is in the top center.

• Remove the pump.

• Rotate the engine by slowly pulling starter handle

until engine coupling half set screw is at bottom.

Loosen set screw using allen wrench and slide

coupling half off of engine shaft.

• Loosen set screw on pump coupling half and

remove coupling half.

• Slide new engine coupling half onto the engine

shaft until the end of the shaft is flush with the inner

portion of the coupling half. (There must be space

between end of the engine support bracket and

coupling half). Tighten set screw.

• Install pump coupling half and key on pump shaft.

Rotate coupling half until set screw faces opening

in shield. Do not tighten set screw.

• Install nylon “spider” onto engine coupling half.

• Align pump coupling half with nylon “spider” by

rotating engine using starter handle. Slide coupling

half into place while guiding three mounting bolts

through holes in pump support bracket.

• Secure with nuts and washers removed earlier.

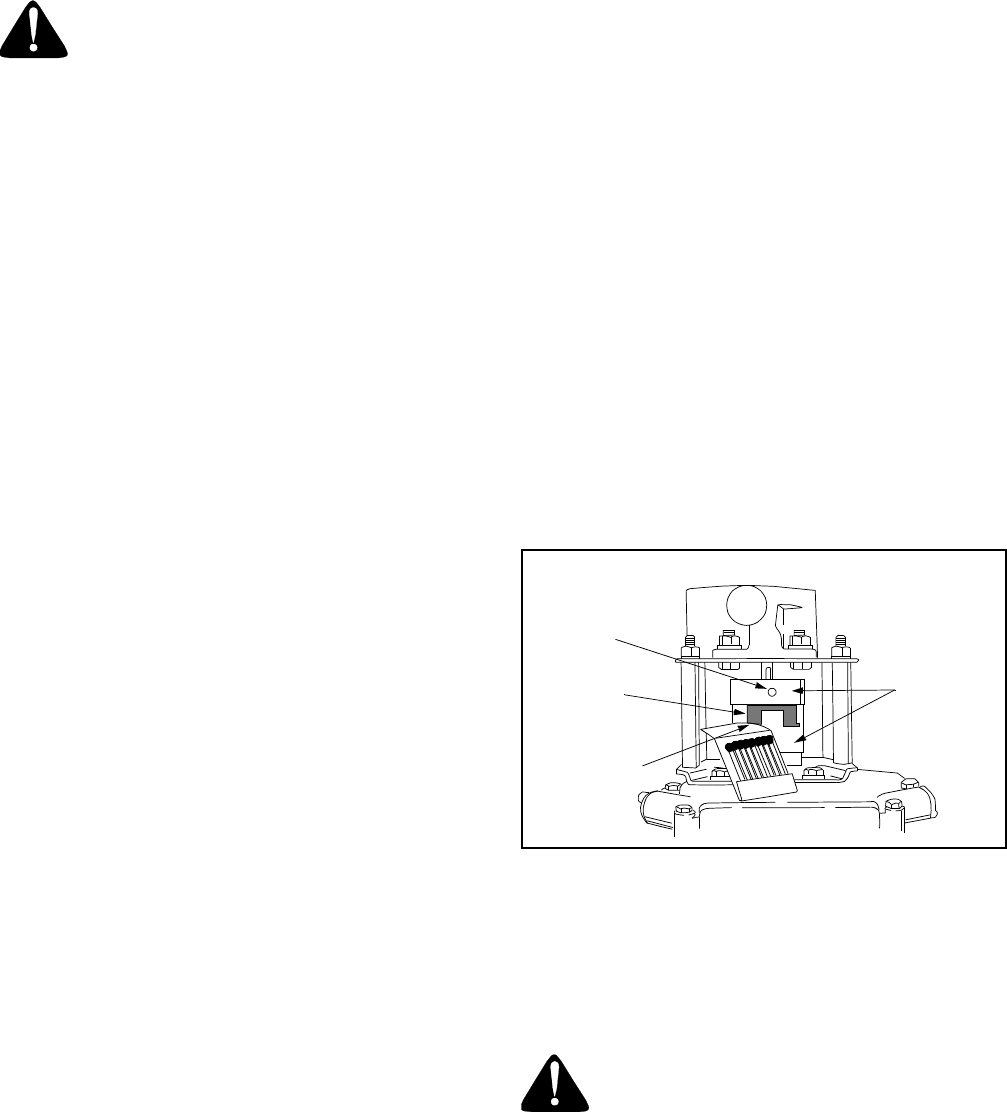

• Set .010” to .060” clearance between the nylon

“spider” and the engine coupling half by sliding a

matchbook cover between the nylon “spider” and

the engine coupling half and moving pump coupling

half as needed. Secure pump coupling half with set

screw. See Figure 11.

NOTE: Make certain proper clearance is obtained

before tightening set screw.

Figure 11

Tires

See sidewall of tire for recommended pressure.

Maximum tire pressure under any circumstances is 30

p.s.i. Equal tire pressure should be maintained on all

tires.

WARNING: Excessive pressure (over 30

p.s.i.) when seating beads may cause tire/

rim assembly to burst with force sufficient

to cause serious injury.

Set

Screw

Nylon

“Spider”

Insert

Clearance

Steel

Coupling

Halves

Gear Pump

Engine