10

Transporting The Log Splitter

• Lower the beam to its horizontal position. Make

certain the beam is locked securely with the

horizontal beam lock.

• Remove the spring clip and clevis pin from jack

stand. Support the tongue and pivot the jack stand

up against the tongue. Secure with the spring clip

and clevis pin previously removed. See Figure 9.

• Attach coupler hitch to a class I or higher 1-7/8” ball

on a towing vehicle, making certain to latch

securely.

• If coupler hitch does not fit on ball, turn adjustment

nut one turn counter-clockwise.

• If coupler hitch is too loose on ball, turn adjustment

nut one turn clockwise.

• Connect the safety chains to the towing vehicle.

• Do not tow faster than 45mph and check local,

state, and federal requirements before towing on

any public road.

• If equipped, plug in the taillights as instructed in the

taillight kit manual included with your log splitter.

NOTE: Use caution when backing up. It is

recommended to use a spotter outside the vehicle.

SECTION 5: ADJUSTING YOUR LOG SPLITTER

WARNING: Do not at any time make any

adjustments without first stopping engine,

disconnecting spark plug wire, and

grounding it against the engine.

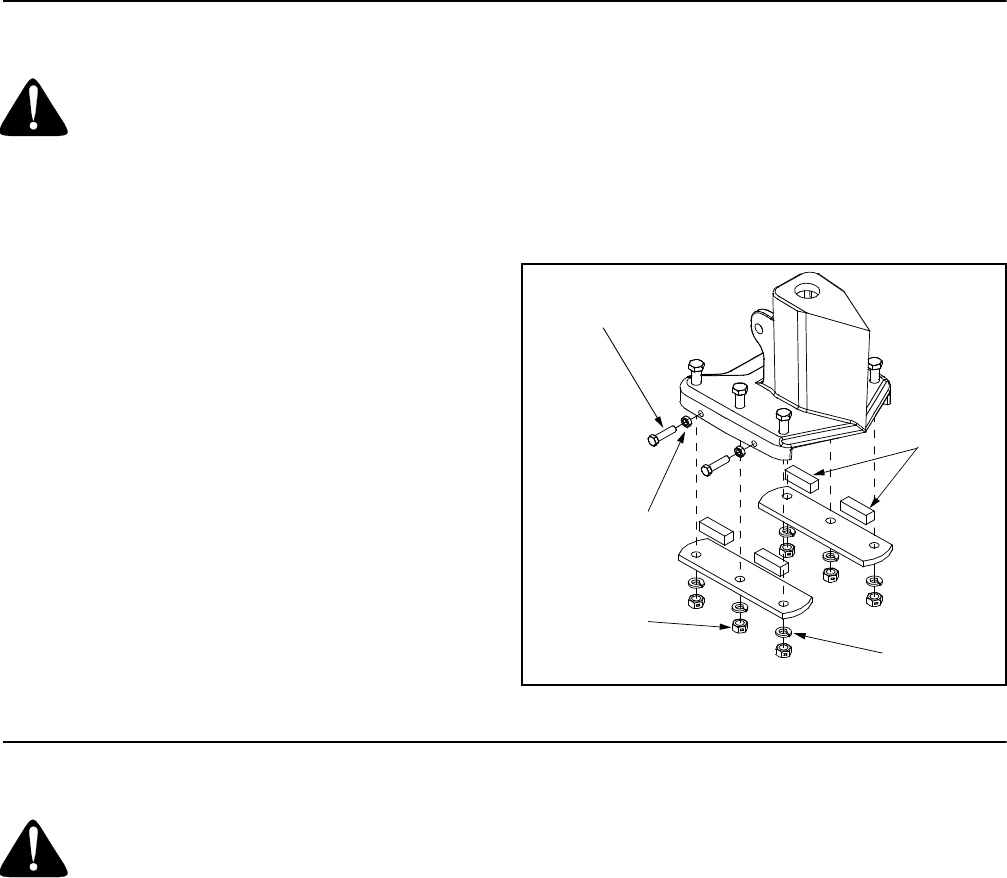

Wedge Assembly Adjustment

As normal wear occurs and there is excessive “play”

between the wedge and beam, adjust the bolts on the

side of the wedge assembly to eliminate the excess

space between the wedge and beam. See Figure 10.

• Loosen the jam nuts on the two adjustment bolts on

the side of the wedge. Turn the adjustment bolts in

until snug and then back them off slowly until the

wedge assembly will slide on the beam.

• Tighten the jam nuts securely against the side of

the wedge to hold the adjustment bolts in this

position.

Gib Adjustment

Periodically remove and replace the “gibs” (spacers)

between the wedge assembly and the back plate.

See Figure 10.

NOTE: The gibs may be rotated and/or turned over for

even wear.

• Loosen the lock nuts under the each back plate and

slide the gibs out.

• Turn or replace the gibs.

• Reassemble the back plate and secure with the

lock washers and lock nuts.

• Readjust the bolts on the side of the wedge

assembly.

Figure 10

SECTION 6: MAINTAINING YOUR LOG SPLITTER

WARNING: Before cleaning, lubricating,

repairing, or inspecting, disengage the

control lever and stop engine. Disconnect

the spark plug wire and ground it against

the engine to prevent unintended starting.

Hydraulic Fluid

Check the hydraulic fluid level in the log splitter

reservoir tank before each use. Maintain fluid level

within the range specified on the dipstack at all times.

Change the hydraulic fluid in the reservoir every 100

hours of operation. Disconnect the suction hose from

the bottom of the reservoir tank and drain the fluid into a

suitable container. Refill using only Dexron III automatic

transmission fluid or 10W AW hydraulic fluid.

Be aware of the environment when disposing of

used petroleum products. Please dispose of used

hydraulic fluid and engine oil at approved recycling

centers.

Hex Jam Nut

Adjustment

Bolt

Gibs

Lock Nut

Lock

Washer