[5] Tightening torque specifications

Repair

P 19/ 19

[4] DISASSEMBLY/ASSEMBLY

[4]-9. Ignition system (cont.)

CHECKING SPARK PLUG

(1) Remove Plug cap from Spark plug, then Spark plug from Cylinder head complete with the supplied socket wrench.

Note: If the electrodes of Spark plug are wet, wipe them with a rag then dry them with an air blower.

(2) Using a wire brush, carefully clean up carbon deposits (if any) from the electrodes and the ceramic insulator around

the center electrode.

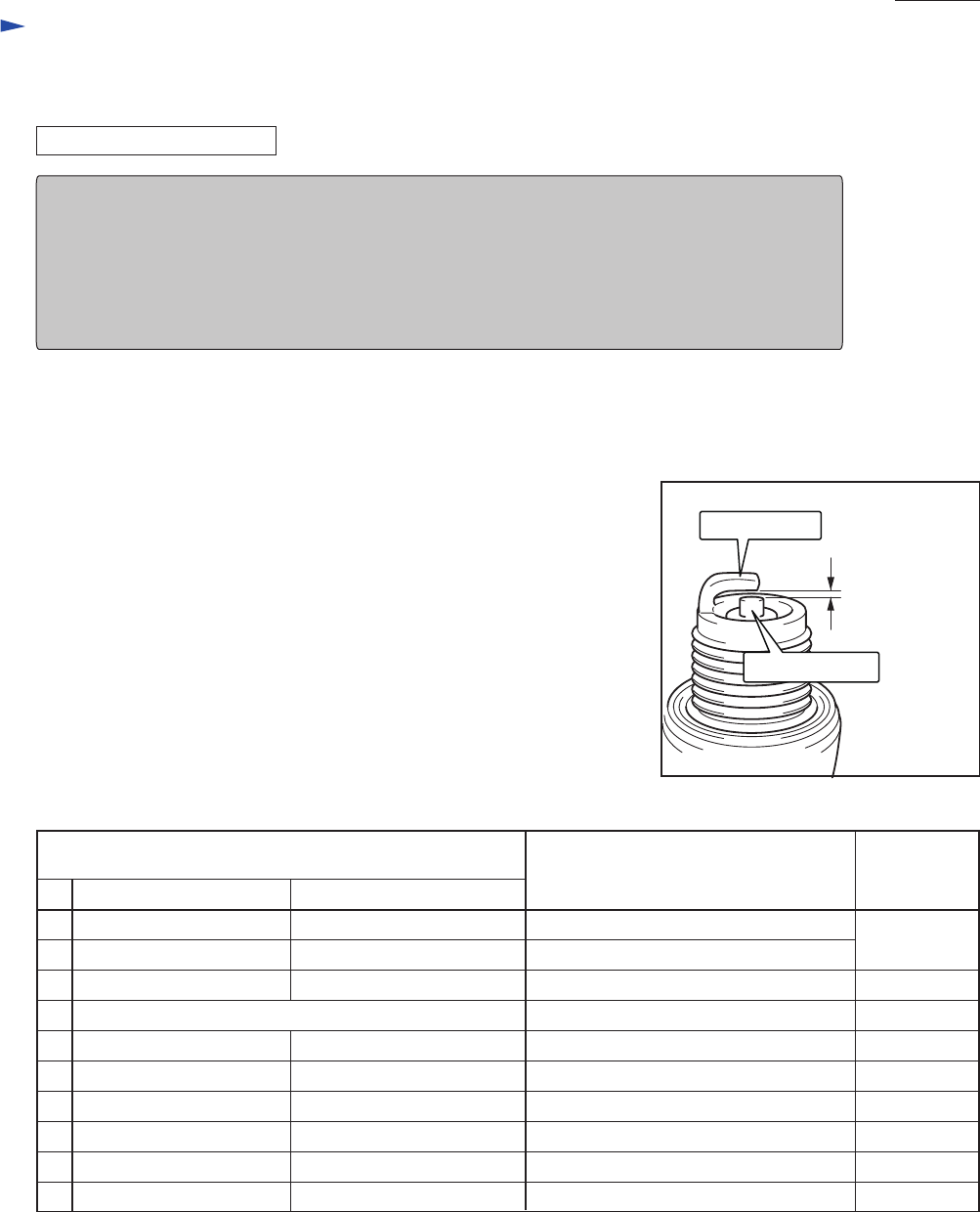

(3) Adjust the electrode gap to 0.5mm by carefully bending the side electrode.

Use Feeler gauge set (1R366) to check the gap width:

between the center electrode and the side electrode, insert 0.5mm leaf

of Feeler gauge set. (Fig. 42)

(4) Install another Spark plug into spark plug hole to prevent air/fuel mixture

from leaking outside of engine.

(5) Connect the removed Spark plug with Plug cap, then ground the threads

of Spark plug to a proper metal part of the engine.

(6) With Stop switch on, pull Recoil starter knob gently and check for spark.

Note: It is hard to see the spark in a bright location.

Therefore, be sure to do the check in a shady but well-ventilated place.

(7) If spark is not produced, replace Spark plug with a new one,

then check for spark by following the procedure (1) to (6) once again.

WARNING !!

• When a spark is produced, high-voltage current is delivered from Ignition coil to Spark plug.

It is, therefore, very dangerous to pull Recoil starter knob with your hand on Ignition cable.

Be sure to keep your hands off from Ignition cable when checking for spark.

• Fuel is extremely flammable and fuel vapors are explosive.

Therefore, clean up spilled fuel before starting to check for spark.

Also, be careful not to do the check near Carburetor.

Fig. 42

Electrode gap

must be 0.5mm.

side electrode

center electrode

Cushion Tank complete M6x30 Hexalobular socket head bolt

7

Cutting arm Cylinder block complete M6x25 Hexalobular socket head bolt

30Cutting arm Belt cover M8 Hex nut

3Front inner holder M6x30 Hexalobular socket head bolt

12Crank case Cylinder block M6x30 Hexalobular socket head bolt

12Cylinder head complete Cylinder block M6x35 Hexalobular socket head bolt

40Flywheel Crankshaft M10 Flange nut

38Clutch holder Crankshaft

M10-17 Hex lock nutClutch assembly Crankshaft

Hexagonal portion (M16-24) of Clutch holder

18

Rocker arm M5x9 Hex nutM5 Hex socket head bolt

1

2

3

4

5

6

7

9

8

10 6

Application

(for fastening A to B)

A B

Fastener

Tightening

torque (N.m)