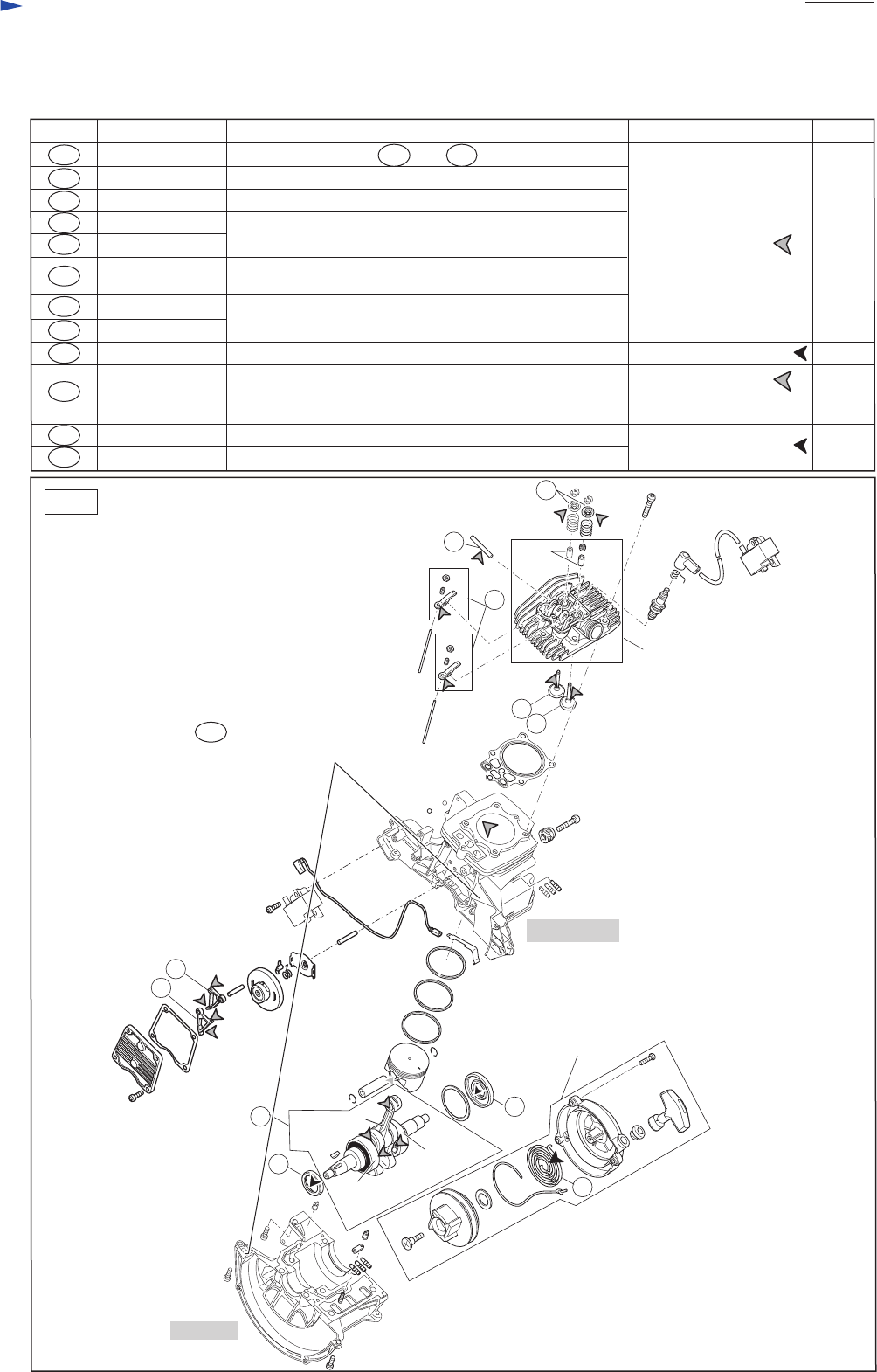

DescriptionItem No. Use for Amount

a little

a little

a little

Lubricant

4-cycle Engine oil

(API grade SM class)

4-cycle Engine oil

(API grade SM class)

Makita grease N No. 2

[3] LUBRICANT/ ADHESIVE APPLICATION

Retainer (2 pcs.)

Contact surface with the holes of Rocker arm assembly

Contact surface with the inner periphery of Valve guide

Contact surface with Piston

• Contact surface with Push rod

• Contact surface with Cam gear complete

• Steel balls in Ball bearings 6204LU and 6204

• Hole of Connection rod to pass Piston pin in Piston

• Needle cage in the other hole of Connection rod

Push rod (2 pcs.)

Exhaust valve

Intake valve

Cam lifter L

Pin 5 Contact surface with the holes of Cylinder head assembly

Repair

Inner periphery

a littleMakita grease N No. 2

Inner periphery

Oil seal 17

Cam lifter R

Crankshaft

complete

Oil seal L

P 3/ 19

109

112

117

Cylinder head

complete

Starter assembly

Ball bearing

6204LU

Ball bearing

6204

Connecting

rod

Valve

guide

119

120

140

138

134

133

Contact surface with 119 and 120

109

112

117

119

120

Cylinder block

complete

123

123

133

134

138

185

208

140

185

208

Spiral spring Entire surface

Apply the following grease/ oil to protect parts and product from unusual abrasion.

Note: After assembly, supply 220cc of 4-cycle engine oil from the inlet of machine before trial run.

When disassembling the engine, put ThreeBond 1215 to the matching surface of Crank case and Cylinder block. (Fig. 66)

Cylinder block complete

(It consists of Cylinder block

and Crankcase)

Fig. 1

Crankcase

Cylinder block