ENGLISH

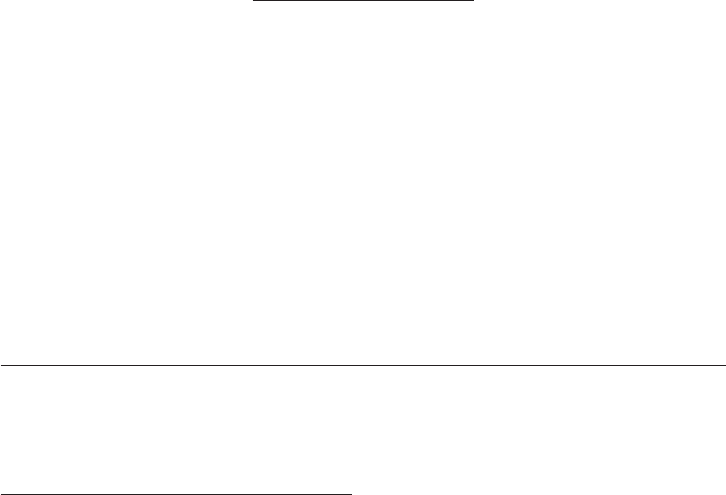

Explanation of general view

1 Loosen

2 Tighten

3 Hold

4 Wing nut

5 Spring washer

6 Flat washer (small)

7 Base

8 Flat washer (large)

9 Bolt

10 Trimmer shoe

11 Adjusting screw

12 Scale

13 Bit protrusion

14 Nut

15 Graduation

16 Wing bolt

17 Amount of chamfering

18 Switch lever

19 Workpiece

20 Feed direction

21 Bit revolving direction

22 (View from the top of

the tool)

23 Correct bit feed direction

24 Trimmer shoe, straight guide

or trimmer guide

25 Bolt

26 Guide plate

27 Straight guide

28 Flat washer

29 Wave washer

30 Wing nut

31 Clamp screw (A)

32 Center hole

33 Nail

34 Adjusting screw

35 Clamp screw (B)

36 Trimmer guide

37 Bit

38 Guide roller

39 Screws

40 Screwdriver

41 Templet guide

42 Convex portions

43 Straight bit

44 Templet

45 Distance (X)

46 Not available

47 Not available

48 Not available

49 Not available

50 Not available

51 Not available

52 Not available

53 Not available

54 Not available

55 Limit mark

56 Brush holder cap

SPECIFICATIONS

Model 3704

Collet capacity ..................................... 6mm or 1/4’’

No load speed (min

–1

) ................................... 30,000

Overall length ............................................... 310 mm

Net weight .......................................................1.5 kg

•

Due to our continuing program of research and

development, the specifications herein are subject

to change without notice.

•

Note: Specifications may differ from country to

country.

Power supply

The tool should be connected only to a power supply

of the same voltage as indicated on the nameplate,

and can only be operated on single-phaseAC supply.

They are double-insulated in accordance with Euro-

pean Standard and can, therefore, also be used from

sockets without earth wire.

Safety hints

For your own safety, please refer to the enclosed

safety instructions.

ADDITIONAL SAFETY RULES ENB054-1

1. Hold tool by insulated gripping surfaces when

performing an operation where the cutting

tools may contact hidden wiring or its own

cord. Contact with a ‘‘live’’ wire will make

exposed metal parts of the tool ‘‘live’’ and

shock the operator.

2. Wear hearing protectionduring extended peri-

ods of operation.

3. Handle the bits very carefully.

4. Check the bit carefully for cracks or damage

before operation. Replace cracked or dam-

aged bit immediately.

5. Avoid cutting nails. Inspect for and remove all

nails from the workpiece before operation.

6. Hold the tool firmly.

7. Keep hands away from rotating parts.

8. Make sure the bit is not contacting the work-

piece before the switch is turned on.

9. Before using the tool on an actual workpiece,

let it run for a while. Watch for vibration or

wobbling that could indicate improperly

installed bit.

10.Be careful of the bit rotating direction and the

feed direction.

11. Do not leavethe tool running. Operate the tool

only when hand-held.

12.Always switch off and wait for the bit to come

to a complete stop before removing the tool

from workpiece.

13.Do not touch the bit immediately after opera-

tion; it may be extremely hot and could burn

your skin.

14.Always lead the powersupply cordaway from

the tool towards the rear.

15.Do not smear the tool base carelessly with

thinner, gasoline, oil or the like. They may

cause cracks in the tool base.

16.Draw attentiontothe needtouse cuttersofthe

correct shank diamater and suitable for the

speed of the tool.

SAVE THESE INSTRUCTIONS.

8

3704 (E) (’100. 11. 29)